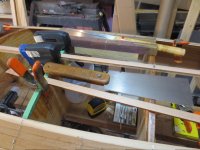

A pic of my stripping tools. Note the stapler with the Blue tape. That holds the 9/16" staples.

The Crude looking saw, is my First Jap Pull saw. I bought a replacement blade, and made a crude handle. I love it ! It has cut strips on every strip canoe I've built.

Also the Home made Mitre box. I've had to splice every strip on this canoe so far !

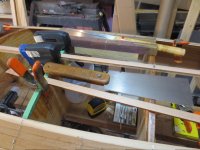

The Crude looking saw, is my First Jap Pull saw. I bought a replacement blade, and made a crude handle. I love it ! It has cut strips on every strip canoe I've built.

Also the Home made Mitre box. I've had to splice every strip on this canoe so far !