Interesting factoids from the Sweet Composites web site:

Fiberglass Yarn 101

This is an introduction to fiberglass yarn terminology, just in case anyone is interested.

(This is just for background — we sell only finished laminating fabrics. We do not sell yarn.) First, we’ll look at the chemical composition of the glass and the difference between E-glass and S-glass.

E-glass, which stands for

Electrical, is the common, all-purpose type. When someone justs says, “fiberglass,” (s)he almost invariably means E-glass.

S-glass, which stands for high-

Strength, is stronger and stiffer and more expensive. What is commonly called S-glass nowadays is actually S2-glass. The original S-glass, sometimes called military S-glass because it was developed for military applications, is somewhat stronger than S2 glass but it is extremely expensive, due to stringent testing and certification requirements of the military. There is no chemical difference between S and S2. The stringent mil-spec testing will pass only the highest quality material, while the commercial S2 material may be slightly less strong and still pass its test. I’m told that military S-glass is now called

lot glass because it is made in a lot or batch, which is then certified as to the processing parameters. It has few commercial applications due to the high cost. S2 glass was developed in the 1960s by Owens-Corning to bridge the gap between E-glass and mil-spec S-glass. When I speak of S-glass I am really speaking of S2-glass and that is generally true in the industry today. Compared to E-glass, S-glass provides about 40% higher tensile and flexural strengths, about 10 to 20% higher compressive strength and flexural modulus, and greater abrasion resistance.

| Glass Composition, % by weight | | |

| Component | E-Glass | S-Glass |

| Silicon dioxide | 52 - 56% | 64 - 66% |

| Calcium oxide | 16 - 25% | Trace |

| Aluminum oxide | 12 - 16% | 24 - 26% |

| Boron oxide | 5 - 10% | — |

| Sodium & Potassium oxides | 0 - 2% | Trace |

| Magnesium oxide | 0 - 5% | 9 - 11% |

| Other oxides & fluorides in trace amounts to make 100%. | | |

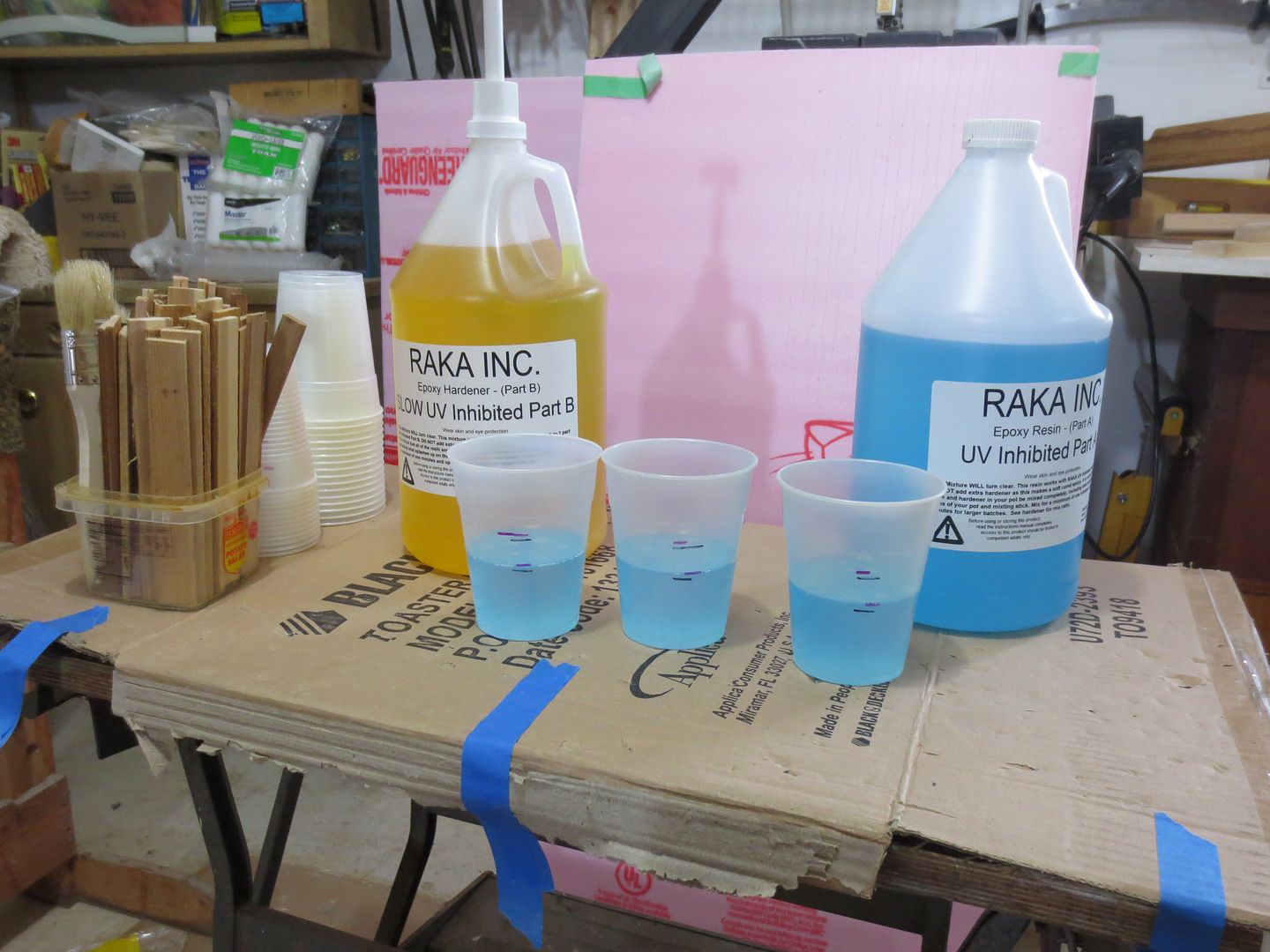

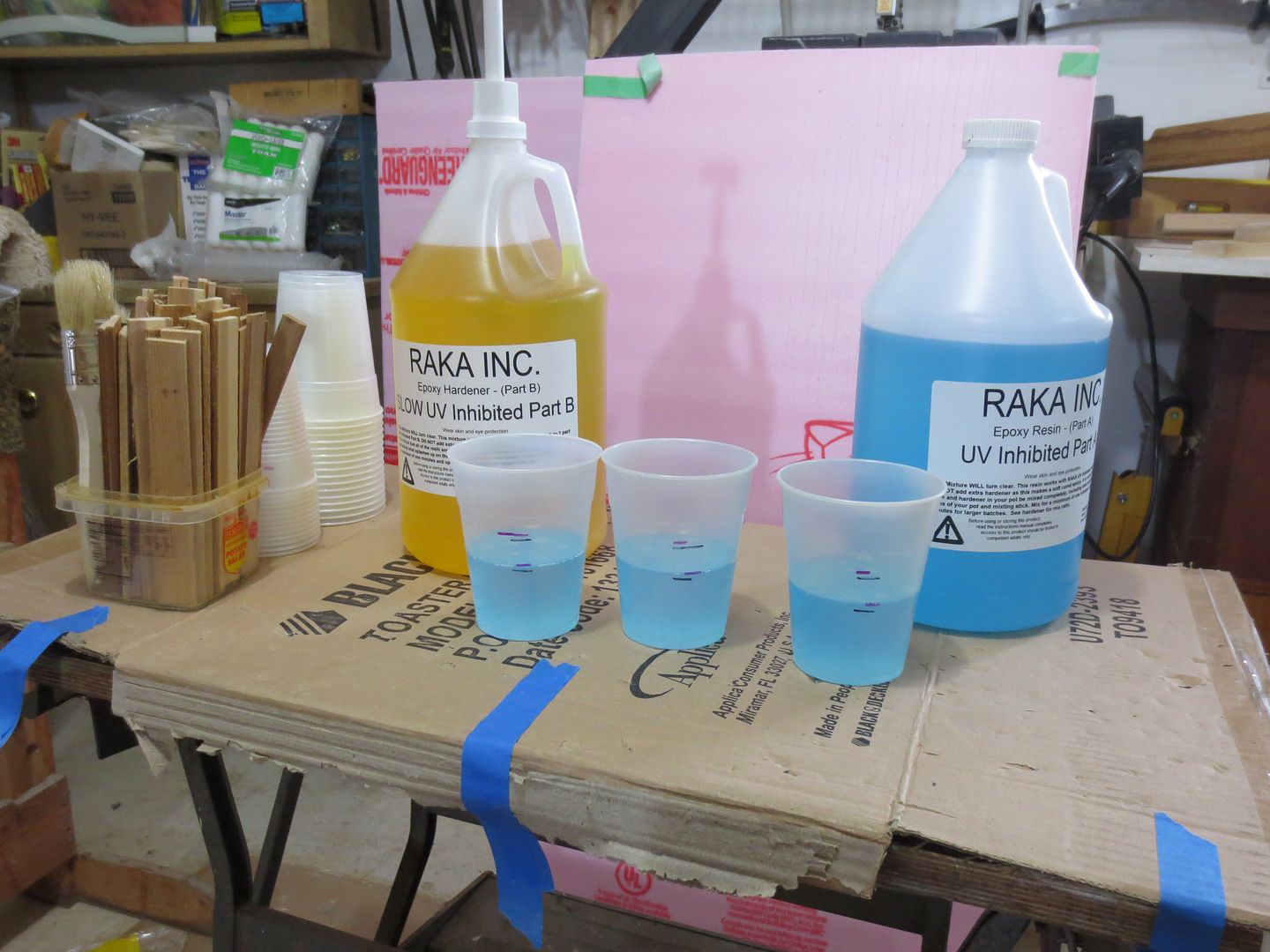

This last pic should have been first. This is how I set things up. A few cups filled with resin, and then with the pump on just the hardener, Even I can't mix them up !

This last pic should have been first. This is how I set things up. A few cups filled with resin, and then with the pump on just the hardener, Even I can't mix them up !