Ok this will be my first build ever of any sort of boat with the exception of building two RC model wood boats.

My original plan was to build two stitch and glue kayaks, However after seeing all the strip build canoes online I have changed my mind and ordered the plans for the Freedom 17 from Bear Mountain boats.

A little about myself, I live up here in Gold Bar, WA. in a RV resort, needless to say I do not have a garage to build it in, and the weather up here is going to be getting colder and the rainy season is coming soon.

My plan is to build a temporary 8ft by 24ft wood frame a cover with [FONT="]rolled clear 6 mil Plastic Sheeting and heat it with a propane heater, hopefully this will work for me.[/FONT]

[FONT="]Right now I am just getting every thing set up for the build, I have picked up my Western Red cedar and the sheeting for the forms and the strong back, the strong back sheeting is going to double as in feed and out feed tables for cutting the strip. I have a 14” Grizzly Polar Bear band saw and a 10” table saw, not sure witch one I am going to use yet.[/FONT]

[FONT="]Ok so bare with me, it is going to take me a while to get every thing set up so that I can get started on the build.[/FONT]

[FONT="]Thank you for looking.[/FONT]

[FONT="]Harold[/FONT]

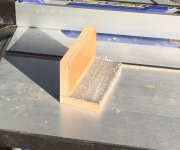

Oh by the way, The cedar in the photos is westurn red cedar.

One 3/4” X 12” X 20 feet

One 3/4” X 10” X 20 feet

One 3/4” X 4” X 20 feet

My original plan was to build two stitch and glue kayaks, However after seeing all the strip build canoes online I have changed my mind and ordered the plans for the Freedom 17 from Bear Mountain boats.

A little about myself, I live up here in Gold Bar, WA. in a RV resort, needless to say I do not have a garage to build it in, and the weather up here is going to be getting colder and the rainy season is coming soon.

My plan is to build a temporary 8ft by 24ft wood frame a cover with [FONT="]rolled clear 6 mil Plastic Sheeting and heat it with a propane heater, hopefully this will work for me.[/FONT]

[FONT="]Right now I am just getting every thing set up for the build, I have picked up my Western Red cedar and the sheeting for the forms and the strong back, the strong back sheeting is going to double as in feed and out feed tables for cutting the strip. I have a 14” Grizzly Polar Bear band saw and a 10” table saw, not sure witch one I am going to use yet.[/FONT]

[FONT="]Ok so bare with me, it is going to take me a while to get every thing set up so that I can get started on the build.[/FONT]

[FONT="]Thank you for looking.[/FONT]

[FONT="]Harold[/FONT]

Oh by the way, The cedar in the photos is westurn red cedar.

One 3/4” X 12” X 20 feet

One 3/4” X 10” X 20 feet

One 3/4” X 4” X 20 feet

Attachments

Last edited: