Almost two months. It's been a fun and busy Fall.

Now that Winter is here, I'm back in the shop.

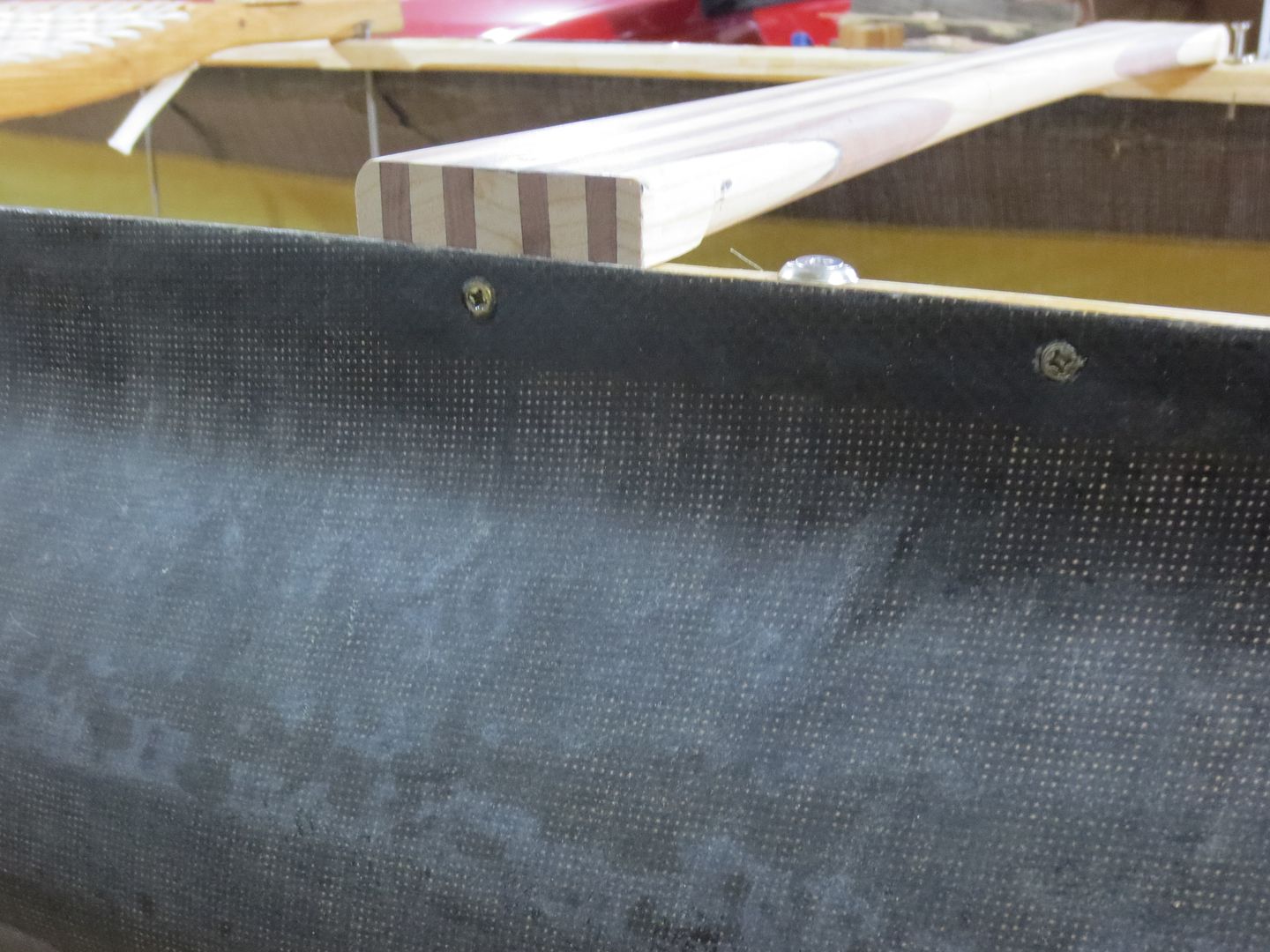

Stripping up the insert for CF Nokomis.

I went with real thin cut cedar, 1/8", as opposed to foam. One I like the look, but more importantly the price ! I put NO value on my labor

a couple of pics.

Jim

Now that Winter is here, I'm back in the shop.

Stripping up the insert for CF Nokomis.

I went with real thin cut cedar, 1/8", as opposed to foam. One I like the look, but more importantly the price ! I put NO value on my labor

a couple of pics.

Jim

Last edited: