Whew Boy! Yep I cut one scupper 3/8" deep and 3" wide. Put my inside gunnel in and cracked it, ugh

. I fixed it the next day. So skip the scuppers.

There are other ways to build scuppers, into the inwhale, other than trying to make it from one piece.

I cut a long, a 3/8" strip, ( full length ), because I have long Ash. Then epoxy 3/8"spacers. That gives me the 3/4" inwhale.

Another method, used by Bruce Kunz, was a three piece inwhale.

The center section, about three feet long, was scuppered with spacers, making it 3/4", and the rest was a solid 3/8" strip.

The widened middle part, 3/4", accommodates hanging the seat, and thwarts. While the rest was narrow, and lighter .

To me this is a great compromise, especially if you don't have access to full length inwhale stock.

Bruce knew how to build!

Some day, I will use Bruces method.

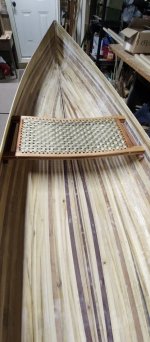

Seat looks great !

I make mine more open. Mine are cooler in the Summer, but this time of year ? I need a pad, to keep my Tush warm and cozy.

I like the photo of you looking at the stem ! I spent a lot of time staring at my canoes during the building process . Trying to reason out my next move. I swear this is half the time it takes me, to build a canoe. I even wake up in the middle of the night, thinking of building !

A chunk of Walnut, with the center drilled out, for your liner rope, would look cool on your hull !

The PVC is fine also .

Come on Spring !

Jim