silly bling stuff... mulling over paint vs vinyl for deck/hull seam, color. With the kevlar interior with yellow tinted UV epoxy fill coat I think some sort of yellow for the deck seam and a smaller pin stripe to hide the somewhat crappy carbon edge line where the combing meets the bright deck. I didn't quite catch the gel stage of the cure when I tried cutting with a razor blade and clammed up that edge a lot more than I would have liked, but it was one of the many late nights in garage. So its a good candidate for a paint stripe now and it sets off the combing too. I do like yellow anyway and it works with the spray skirt in yellow as well. A little bling and good visibility in foul weather for safety reasons too. Now I probably need to get a different color PFD, SOLAS orange is going to clash horribly

Ensemble challenges aside, I was initially planning to paint the stripes and bought a qt of safety yellow a month or so ago, but after reckoning the time and effort required to paint stripes and pondering whether the yellow was really the one I wanted to live with or not I decided to get some vinyl tape in yellow and yellow/gold to try first. Both tape colors appear to pretty close matches in the acrylic urethane I'm using for UV clear. After applying the yellow/gold tape on the sanded surface I think I like it better than the brighter safety yellow.

Over the course of day or two though I talked myself out of painting stripes entirely for now and just clear coat instead. I'll try each color tape for a while and decide which one I like best before committing to paint. Or maybe I'll just stay with the tape since I can change it completely in less than 30 minutes. Redoing painted stripes would be several hours work over several days. I figure if vinyl tape is good enough for Savage River its probably good enough for me too...

On to clear coating. For those keeping score at home. I'm using a marine grade acrylic urethane by Blue Water. Its an Awlcraft 2000 knock-off that is also rated below the waterline which Awlcraft is not.

https://www.bottompaintstore.com/to...ermarine-ironside-urethane-quart-p-28192.html

Why this stuff for a canoe? Well, in past projects I've painted both aluminum jon boats and fiberglass boats as well as aluminum airboats with Dupont Imron, Awlgrip and at the time Ditzler (now PPG) base coat/clear coat systems. These are all substantially more durable coatings compared to anything in consumer grade offerings, of course priced accordingly and far more complex and problematic to apply. I've received excellent long term results with all of them through relatively harsh use too. Like much of what I've done on this project this grade of finish is certainly over kill, but my next project is to build a 16' flats skiff where it won't be:

http://cernyyachtdesign.com/power/swift-skiff-series/guide-skiff/

With this skiff build on the radar I wanted try a different and less expensive advanced coating and decided this canoe would be a perfect sized experiment with clear coating over epoxy as opposed to manufacturer compatible primer and topcoat. (I plan to have some bright work under epoxy on the skiff too)

For those that are not familiar with these coating systems, clear coating (pick your favorite brand) over non-mfr-compatible paints and/or substrates is not for the faint of heart. Once you've conquered a particular combination its generally repeatable, but rarely does it "just" work In this case applying the clear over epoxy was an adventure.

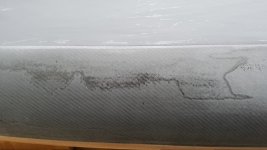

Anticipating "challenges", I started with my test panels and the small parts, rudder pedal cleats and the seat cross member, etc. For prep I went by the manufacturer recommendations sanding at 180-240grit, used the etching solution (think mild battery acid) on raw surface, then cleaning with the appropriate solvent before thinning and spraying, but still had incompatibility issues. Micro craters pin point size to about 1/8" or so and some kind of unexplained blush in places. Some of the problems were due to contaminates in my air system and some had to be tiny amounts of mold release wax I didn't completely remove. I replaced the oil/filter/drier and added additional inline filter at the gun. I sold my Binks conventional spray guns to a buddy many years ago and went HVLP and never looked back (I don't miss spraying 50lbs at the gun...). My first and only HVLP gun is a Porter Cable that has been a dedicated conversion varnish gun for over a decade and provided excellent finishes, but wasn't atomizing this high solid coating well enough with the 1.5mm fluid tip and air head at 15-20% thinning ratio and 22-30lbs at the gun. I took it apart and meticulously cleaned it and ran acetone, lacquer thinner and finally the 275 solvent for the SM-266 clear through it and tried some more, full fan, 4-6" away, farther, closer, dialed back fan, more paint, less paint etc. I ended up having to thin to about 40% by volume before I could get a decent flow out, but at that ratio the clear coat left on the surface was too thin and very difficult to avoid runs when going for a wetter application (spec calls for 4mil wet film thickness).

Long story short I bought a DeVilbis Finishline 4 FLG-670 hoping to get better results and it was fine. The winning formula is the 1.3mm tip, 20% thinner, 28lbs at the gun, 6" hold off with fan at about 90% wide open and 75% overage on each pass. Regardless, of all that I got the best results laying down a light coat of clear, let it cure overnight or at least 18hrs (mfr recommends 24) light sand then apply light tack coat, 2 min flash off and wet coat. Seems first layer to touch the epoxy no matter how well prepped will micro crater in places, but following a light sanding subsequent coats flow nicely without issue anywhere. Maybe re-etching and re-washing with thinner enough would do it, but didn't work to the extent I tried. Seems like there needed to be a light film down first.

I burned through 2 qts of clear stumbling through the issues and small parts and ended up with only about 1.5 coats on the canoe, love bug tracks and all. Did I mention my compressor of 14 years died a slow miserable death this Friday afternoon with the 2nd to last pint of finish in the gun too.

Spraying outside and finagling around the combing riser it's taking about a pint to cover the top and sides down to the tape line at the graphite scuff coat on the football. I'm figuring it will take about 3-4 coats to get the build I want before compound, glaze and wax. So I'll need at least 2 more quarts of clear and its f'ing done. Nothing but rain in the forecast into next weekend though too, so probably going to be another two weeks, arrggghhh...

, before final ironing.