Some manufacturers offer factory installed skid plates, either internal or external. Which would you choose to offer best protection? I know some prefer to add them after wear becomes an issue, but I'm a prevention kind of guy, especially given the remoteness of some trips. So, I'm just wondering which design works best.

-

Happy Birthday, Charles Lindbergh (1902-74)! 🛩️🗽🗼

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Internal or External Skid Plates?

- Thread starter Black_Fly

- Start date

none.. I have been down the Yukon River and the Missinaibi and remote trips in Canada for years and skid plates are useless.. We did have some on one boat and hit a rock head on which put a hole in the skid plate ( Northern Ontario). They are typically made of Kevlar felt which is garbage.

Wait till you need repairs then do a smooth repair with fiberglass peel ply and resin

Interior skid plates are a marketing ploy, All that means is that there is an extra layer of fabric in the stems. And there should be anyway.

Wait till you need repairs then do a smooth repair with fiberglass peel ply and resin

Interior skid plates are a marketing ploy, All that means is that there is an extra layer of fabric in the stems. And there should be anyway.

I don't know. I've installed skids on older boats and new ones. If the stem is damaged, it's still damaged under the skid, making for a more fragile point of impact. Best protection is the original stem - I prefer to keep mine solid when you know it's going to be pounded. I've had good luck with kevlar skids on both royalex and kevlar.

I assume by internal skids they mean extra cloth built into the stems while it's in the mold and external stems means kevlar felt added after it's out of the mold.

If that's the case I'd take internal any day for less weight and less ugly.

I use dynel for skids on my boats and have been extremely happy with its performance. It's not super thick like kevlar felt and is easy to blend into the hull even if added after the build.

Alan

If that's the case I'd take internal any day for less weight and less ugly.

I use dynel for skids on my boats and have been extremely happy with its performance. It's not super thick like kevlar felt and is easy to blend into the hull even if added after the build.

Alan

When I hear "skid plate" I think of an abrasion plate, i.e, something to protect the structure of the boat's stem and sometimes keel line from abrasion damage. Something inside the structure of the boat does nothing to protect against abrasion, although more layers of material will increase stiffness and usually resistance to cracking and other structural damage. Depending upon the conditions in which you paddle, your boat might be at risk of wearing through the gel coat (if present) and into or through the outer layers of cloth. If so, you can add one or more additional layers of fabric to cover the vulnerable areas. This can be done before or after damage occurs.

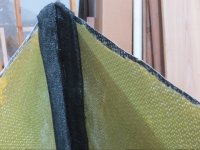

I agree that the common Kevlar felt skid plate material is garbage. Although the aramid fibers may be strong (at least in tension), in a felt material the fibers are very short and compressed and not interlaced with each other in any effective way, and are bound together only by resin. Felt material soaks up a lot of resin so the strength to weight ratio of Kevlar felt is very poor. Furthermore, aramid is not all that strong in compression and does not have as good resin binding as other fabrics. A skid plate at the stem is subjected primarily to compressive and sheer forces, not tension. Also, the material becomes quite thick after soaking up resin and the proud edges cannot be easily feathered. Kevlar felt has become popular because it is easy to work with. It holds its shape after cutting and hey, it's Kevlar so it's got to be strong, right?"

If you want to apply an external skid plate there are much better choices of material. Dynel is good having excellent abrasion resistance but it is a bit resin thirsty. S fiberglass is also very good. It has greater strength than Dynel of the same fabric weight although perhaps a bit less abrasion resistance and does not take up quite as much resin. Either Dynel or S 'glass can be used to make a much thinner plate than Kevlar felt that has greater actual strength, much less weight, and the edges can be very nicely feathered.

I agree that the common Kevlar felt skid plate material is garbage. Although the aramid fibers may be strong (at least in tension), in a felt material the fibers are very short and compressed and not interlaced with each other in any effective way, and are bound together only by resin. Felt material soaks up a lot of resin so the strength to weight ratio of Kevlar felt is very poor. Furthermore, aramid is not all that strong in compression and does not have as good resin binding as other fabrics. A skid plate at the stem is subjected primarily to compressive and sheer forces, not tension. Also, the material becomes quite thick after soaking up resin and the proud edges cannot be easily feathered. Kevlar felt has become popular because it is easy to work with. It holds its shape after cutting and hey, it's Kevlar so it's got to be strong, right?"

If you want to apply an external skid plate there are much better choices of material. Dynel is good having excellent abrasion resistance but it is a bit resin thirsty. S fiberglass is also very good. It has greater strength than Dynel of the same fabric weight although perhaps a bit less abrasion resistance and does not take up quite as much resin. Either Dynel or S 'glass can be used to make a much thinner plate than Kevlar felt that has greater actual strength, much less weight, and the edges can be very nicely feathered.

G

Guest

Guest

What Alan and Pete said.

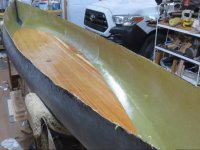

I am very happy with Dynel and graphite powder skid plates, with the Dynel and epoxy skid plates laid hand-compressed under peel ply.

http://www.canoetripping.net/forums...ssions/diy/75518-diy-canoe-skid-plate-install

YC, I agree with most of that. “Typical” kevlar felt skid plates are near garbage. I agree with waiting until the stem scrapes and scratches show exactly where (Dynel) skid plates need to be installed. I agree that “internal skid” plates are not really skid plates, just additional partials of cloth laid where they should be.

But we have skid plates on most of our boats; some old kevlar felt kit crap, some DIYed from glass cloth or thick bi-axial glass tape, some Dynel, graphite powder and black pigment.

All of them show wear; the thick, once rough textured kev felt has worn baby butt smooth, the glass has scrapes and scratches and the abrasion resistant Dynel skid plates (installed with a mix or West 105/206 and G/flex) are holding up best of all. Compressed under peel ply those skid plates are ungurgley flush with the hull (and weigh a LOT less than resin saturated kev felt).

P1080370 by Mike McCrea, on Flickr

P1080370 by Mike McCrea, on Flickr

I would prefer to install my own skid plates, especially if the manufacturer OEM version uses kevlar felt. I would prefer to install them after a few trips, when I can see how and where my load and abuse is wearing at the stems, but I have installed best-guess skid plates on a new canoe that was going on the Tripping Truck and not coming back to the shop for months.

I am very happy with Dynel and graphite powder skid plates, with the Dynel and epoxy skid plates laid hand-compressed under peel ply.

http://www.canoetripping.net/forums...ssions/diy/75518-diy-canoe-skid-plate-install

We did have some on one boat and hit a rock head on which put a hole in the skid plate ( Northern Ontario). They are typically made of Kevlar felt which is garbage.

Wait till you need repairs then do a smooth repair with fiberglass peel ply and resin

Interior skid plates are a marketing ploy, All that means is that there is an extra layer of fabric in the stems. And there should be anyway.

YC, I agree with most of that. “Typical” kevlar felt skid plates are near garbage. I agree with waiting until the stem scrapes and scratches show exactly where (Dynel) skid plates need to be installed. I agree that “internal skid” plates are not really skid plates, just additional partials of cloth laid where they should be.

But we have skid plates on most of our boats; some old kevlar felt kit crap, some DIYed from glass cloth or thick bi-axial glass tape, some Dynel, graphite powder and black pigment.

All of them show wear; the thick, once rough textured kev felt has worn baby butt smooth, the glass has scrapes and scratches and the abrasion resistant Dynel skid plates (installed with a mix or West 105/206 and G/flex) are holding up best of all. Compressed under peel ply those skid plates are ungurgley flush with the hull (and weigh a LOT less than resin saturated kev felt).

P1080370 by Mike McCrea, on Flickr

P1080370 by Mike McCrea, on FlickrSome manufacturers offer factory installed skid plates, either internal or external. Which would you choose to offer best protection? I know some prefer to add them after wear becomes an issue, but I'm a prevention kind of guy, especially given the remoteness of some trips. So, I'm just wondering which design works best.

I would prefer to install my own skid plates, especially if the manufacturer OEM version uses kevlar felt. I would prefer to install them after a few trips, when I can see how and where my load and abuse is wearing at the stems, but I have installed best-guess skid plates on a new canoe that was going on the Tripping Truck and not coming back to the shop for months.

I did some Dynel plates on a friend's drift boat this past summer and they seem to be holding up quite well. That boat sees a lot of contact.

I've always liked working with 4 oz S cloth and I just made a set of skids for another friend's canoe using a double layer of that material. Not enough usage yet to comment on their performance but it sure laid out nice with the peel ply technique.

I've always liked working with 4 oz S cloth and I just made a set of skids for another friend's canoe using a double layer of that material. Not enough usage yet to comment on their performance but it sure laid out nice with the peel ply technique.

Keep in mind that if you wet foot and don't ram the shore in solo boats often the abrasion is in a different place than the ends.. I just wonder why get a new boat and sand it like rocks would and guess where you need the skid plate. Wait till you see where you will need it as Mike mentioned.

Tandems have weight in the ends pinning them and solos often have wear further back from the actual stem as the ends are light.

Tandems have weight in the ends pinning them and solos often have wear further back from the actual stem as the ends are light.

I've been using 4 layers of s-glass (no easy access to dynel), on my yellow canoe (royalex) they can hardly be seen, over the course of a summer I can develop some wear spots in the glass and if I get involved in a heavy collision maybe a tear. In the spring I just put on another layer or two. Probably 12 layers on parts of the bow now and it's still thinner that your standard kevlar felt skids.

I really abuse that boat, more than half of the outer vinyl skin is gone! My specialty is dragging fully loaded through dry river beds.

I really abuse that boat, more than half of the outer vinyl skin is gone! My specialty is dragging fully loaded through dry river beds.

G

Guest

Guest

I've been using 4 layers of s-glass (no easy access to dynel), on my yellow canoe (royalex) they can hardly be seen, over the course of a summer I can develop some wear spots in the glass and if I get involved in a heavy collision maybe a tear. In the spring I just put on another layer or two. Probably 12 layers on parts of the bow now and it's still thinner that your standard kevlar felt skids.

I really abuse that boat, more than half of the outer vinyl skin is gone! My specialty is dragging fully loaded through dry river beds.

My homeriver is often low water draggy across too shallow gravel bars, so the stems, the stern stems especially, see some abuse. Add in the occasional coastal oyster bar or limestone and there can be a lot of scraping and grinding going on. Just hauling the hull up onto a ledge site is abusive.

Nothing has held up as well to abrasion as external Dynel skid plates. One layer of Dynel would be less heavy and sit more flush than 12 layers of fiberglass.

If you can find/order a yard of Dynel (and a yard of release treated peel ply I’d give that a shot instead of adding a 13[SUP]th[/SUP] (14[SUP]th[/SUP]. . . . .15[SUP]th[/SUP]) layer of glass.

Dynel

https://www.jamestowndistributors.com/userportal/show_product.do?pid=4214

Peel Ply (aka vacuum bagging release fabric)

https://www.jamestowndistributors.c...3754&familyName=Vacuum+Bagging+Release+Fabric

I expect that Composites Canada sell the same.

https://compositescanada.com/

Dynel is purportedly not as impact resistant as some other fabrics in layers, but I have smacked the crap out of a few rocks with no cracks or missing chunks.

I've been using 4 layers of s-glass (no easy access to dynel), on my yellow canoe (royalex) they can hardly be seen, over the course of a summer I can develop some wear spots in the glass and if I get involved in a heavy collision maybe a tear. In the spring I just put on another layer or two. Probably 12 layers on parts of the bow now and it's still thinner that your standard kevlar felt skids.

I really abuse that boat, more than half of the outer vinyl skin is gone! My specialty is dragging fully loaded through dry river beds.

I don't know if you're "Hogtown" is real or imaginary...

Any one of us here in the US can readily buy some Dynel and ship to you for the associated costs.

I spoke to a Northstar rep. He said Dynel is not preferred to kevlar as an external skid plate because it is too thin and the long strands prevent it from doing what such a plate is supposed to do...that is skid across rocks. It's not about impact resistance at all...except maybe for ww applications. Short fiber Kevlar is more wear durable for the type of repeated friction that a skid plate is designed to absorb.

Dynel being thin is the advantage over kevlar felt skid plates, and that you can feather it in to the hull shape. With kevlar you have that hard edge all around. I agree that dynel will wear easier than kevlar felt, but you just put another little strip on when it wears through, or build up a few layers to begin with.. Dynel also has little impact resistance. I've chipped off chunks above the water line where the bow comes in contact with rocks.(Mike, maybe using the gflex epoxy makes the difference here?) I think the reps conclusion about it not skidding on rocks is wrong from my experience.

Mark

Mark

Last edited:

Cool. Boat is ordered. Late February. I also had them install a foot brace and tug eyes. Can't wait. Thanks for helping make these decisions. I'm thinking Missinaibi first.

Cool. Boat is ordered. Late February. I also had them install a foot brace and tug eyes. Can't wait. Thanks for helping make these decisions. I'm thinking Missinaibi first.

Which part and what month? Some of us have done it. As for me the Lower and the water level Low.. So low that below the confluence of the Mattagami there were sandstorms.

I'm in agreement with Mark. I have had boats with kevlar and they do their job but look like a giant booger on the ends of a boat. I've been using Dynel mix with resin and G-Flex mix for a while now and several boats. My WW hull has taken some pretty good hits and all I have to do at the end of the day is slap a little touch up paint to the skid plate and never had a problem with chips or wearing. We all have our preferences on what to use on our boats.

dougd

dougd

Yeah if you plan on doing the lower part don't leave it too late in the Summer and check water levels before you go. Regardless you should plan for an exit at Moose River Crossing if necessary because of low water, you won't really be missing anything on the lower Moose. Good to go to Moosonee if you've never been there but nothing really warrants a second visit.

Similar threads

- Replies

- 14

- Views

- 1K