This is an interesting discussion, coming from an aerodynamics background with my first ever homemade paddle roughed out and waiting for my return to the cabin to finish it.That's a great question(s). I'm never quite certain about the term "dihedral" as it pertains to paddle blades, as I would presume that almost all blades are "dihedral" unless each face is completely flat, i.e., the same thickness from edge to edge. Camber, on the other hand, refers to the curvature of the blade, from edge to edge, being thicker in the center, therefore convex.

My blades are all gently cambered, thus convex. They also gently taper from thin at the tip to nearly the thickness of the shaft, at the throat. There is no defined "spine" except, perhaps a tiny bit at the throat. Regarding concavity, except for a minimal bit, right art the throat, concavity should be avoided (in my opinion). Any concavity results is turbulence, especially when doing in-water recoveries.

In summary: It is important that the camber on each facet be matched and also be matched on the front and rear faces of the blade. Blades with mismatched camber will not slice cleanly. If there is greater camber on one face of the blade than the other, the blade will tend to "lift" toward the side with greater camber (Bernoulli's principle), when sliced. Any significant spline, will cause turbulence, and thus is to be avoided.

In aircraft wing design, "camber" usually refers to the mean line curvature, which is the average of the upper and lower surface curvature (which are sometimes referred to as the "upper surface camber" and the "lower surface camber"). A symmetrical airfoil (same curvature top and bottom) has zero mean camber; the mean line is a straight line. Airfoils are defined by a thickness distribution (how the thickness varies from front to back, the actual thickness in percent of chord (the length from front to back, typically 10-15%). That thickness distribution is superimposed on the cambered (or straight) mean line to define the upper and lower surfaces.

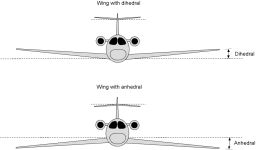

"Dihedral" is an angle, not a curve, referring to the upwards angle of the wings from the center to the tips, viewed from the front to the tips. I could see it applying to the blade faces if they're flat tapered and not curved.

A cambered airfoil will produce lift (which some attribute to Bernoulli, though it's not a simple as that) unless it's angled nose down to compensate for that, which creates more drag than a symmetrical (uncambered) section producing zero lift. Also if a paddle blade has any mean camber, it will tend to twist when slicing through the water. But there are one sided paddles, no? A cambered blade could be more efficient during the pulling stroke, at the expense of slicing behavior.