I believe that there are financial, tooling, shop space, and time costs that deter many people from building their own stripper or wood/fabric canoes.

"Yeah, building seems kind of interesting but":

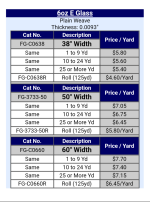

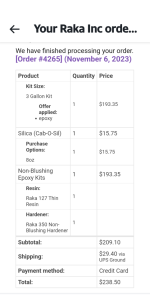

- "I don't want to spend the money on expensive or hard-to-find cedar/ash/mahogany/brass/copper/canvas/filler/whatever."

- "I don't have all those fancy forms, strongbacks, table saws, band saws, circular saws, routers, sanding machines, clamps, pulleys, come-alongs, whatever."

- "I don't have a shop in my house."

- "I'm busy and have a family and don't have hundreds of hours to spend on a big project like a canoe."

Your mission, members, should you choose to accept it, is to reply to one or more of these excuses by explaining how a canoe can be built on a low or inexpensive budget of materials, tools, space and/or time.

"Should you or any member of your CTN team be caught or killed, the administrator will disavow all knowledge of your actions."

"Yeah, building seems kind of interesting but":

- "I don't want to spend the money on expensive or hard-to-find cedar/ash/mahogany/brass/copper/canvas/filler/whatever."

- "I don't have all those fancy forms, strongbacks, table saws, band saws, circular saws, routers, sanding machines, clamps, pulleys, come-alongs, whatever."

- "I don't have a shop in my house."

- "I'm busy and have a family and don't have hundreds of hours to spend on a big project like a canoe."

Your mission, members, should you choose to accept it, is to reply to one or more of these excuses by explaining how a canoe can be built on a low or inexpensive budget of materials, tools, space and/or time.

"Should you or any member of your CTN team be caught or killed, the administrator will disavow all knowledge of your actions."