- Joined

- Aug 10, 2018

- Messages

- 2,139

- Reaction score

- 7,202

I've come to enjoy building canoes during the winter and experimenting with different wood combinations. The decision of what to build is normally tough but was made easy this time as the plans for my 2026 build are courtesy of @Alan Gage. Although this hull has been called other things, I'll steer clear of any possible profanity filter edits and simply dub it the Bloodvein II.

This is the revised version of the hull that Alan built for his trip down (and back up) the Bloodvein River. Upon returning, he decided that more rocker was needed so he revised a few of the fore & aft stations before building his composite version. I'll trust his judgment and skip version #1.

The issue of what wood to use was not as simple. I've still got lots of Aspen, Tamarac & White Pine but didn't want to repeat a wood choice yet. I've recently acquired nice supplies of Catalpa, Yellow (Tulip) Poplar and Sassafras but none of them were dry yet.

While helping my daughter find some Walnut for another project, however, I ran across a good deal on some kiln-dried Yellow Poplar, bought 100 board feet (at $1.50/brd ft) and also bought some Walnut that had far too much sap wood to be worth much. I'll have a little more in this build than when I kill the trees myself but I consider that better than waiting for another year.

I took advantage of nice weather today and decided to cut strips in the yard and, at this point, I'm thinking that I may have over-bought on the Poplar. For whatever reason, I've been thinking that I use 60-70 board feet per hull while I know that can't be right (60 feet of White Cedar would weigh 110lbs so, even if 1/2 of the board winds up as sawdust, that would be 50+ lbs of wood before glassing).

The Poplar that I bought is 4/4 (1 inch thick) rough cut, 10 feet long and 14 inches wide on average. I sliced 1 1/2 of these before dark tonight and it's looking like 2 boards might be enough Poplar for the build even though that's only about 20 feet of lumber.

I may count strips on the Raven (which is a similar hull) and I'll need to see if I can get enough clear(ish) heart from the Walnut out boards when I get back to it later this week.

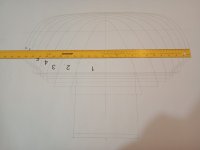

I'm also hoping my architect friend can get the plans printed but, with Christmas mid-week, I might be cutting forms after the first. Nonetheless, it feels good to have the next hull figured out and started.

This is the revised version of the hull that Alan built for his trip down (and back up) the Bloodvein River. Upon returning, he decided that more rocker was needed so he revised a few of the fore & aft stations before building his composite version. I'll trust his judgment and skip version #1.

The issue of what wood to use was not as simple. I've still got lots of Aspen, Tamarac & White Pine but didn't want to repeat a wood choice yet. I've recently acquired nice supplies of Catalpa, Yellow (Tulip) Poplar and Sassafras but none of them were dry yet.

While helping my daughter find some Walnut for another project, however, I ran across a good deal on some kiln-dried Yellow Poplar, bought 100 board feet (at $1.50/brd ft) and also bought some Walnut that had far too much sap wood to be worth much. I'll have a little more in this build than when I kill the trees myself but I consider that better than waiting for another year.

I took advantage of nice weather today and decided to cut strips in the yard and, at this point, I'm thinking that I may have over-bought on the Poplar. For whatever reason, I've been thinking that I use 60-70 board feet per hull while I know that can't be right (60 feet of White Cedar would weigh 110lbs so, even if 1/2 of the board winds up as sawdust, that would be 50+ lbs of wood before glassing).

The Poplar that I bought is 4/4 (1 inch thick) rough cut, 10 feet long and 14 inches wide on average. I sliced 1 1/2 of these before dark tonight and it's looking like 2 boards might be enough Poplar for the build even though that's only about 20 feet of lumber.

I may count strips on the Raven (which is a similar hull) and I'll need to see if I can get enough clear(ish) heart from the Walnut out boards when I get back to it later this week.

I'm also hoping my architect friend can get the plans printed but, with Christmas mid-week, I might be cutting forms after the first. Nonetheless, it feels good to have the next hull figured out and started.