The sooner the better when applying fill coats. Apply your first fill coat, and about an hour or two later, apply the next. If your first coat is still tacky ? It will hold the next coat, and prevent runs. Straight from a System Three Tech !

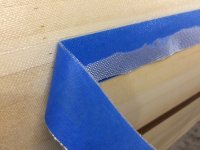

I planned on using Peel Ply like Alan, and yeah it didn't work for me either. On a flat surface, it will save you at least one fill coat. Trouble is ? Peel Ply is at least $8 a yard.

Used Dynel from RAKA, on a fiberglass Snow scoop. Didn't hold up at all ! It cut too easy to have any abrasion resistance. Glad I didn't try it on a canoe !

Jim

I planned on using Peel Ply like Alan, and yeah it didn't work for me either. On a flat surface, it will save you at least one fill coat. Trouble is ? Peel Ply is at least $8 a yard.

Used Dynel from RAKA, on a fiberglass Snow scoop. Didn't hold up at all ! It cut too easy to have any abrasion resistance. Glad I didn't try it on a canoe !

Jim