I seem to do more dreaming and designing than actual building. I have three designs that have yet to be built. At least it's cheaper. I might have some time off unemployed in the next couple months, so once again I'm thinking of a build. I'm thinking a short pack style canoe. 10 ft, but wider and higher prismatic coefficient. Basically something that can fit in the bed of my truck, small and light enough to toss in any creek or river around town, and able to drag over any downed trees and exposed rocks. I want it wide and stable enough to pole it because I'll mostly be in shallow waters. The design will come up later, once it's more complete.

This has got me thinking of the most common problem I deal with. How do I build a canoe that can handle frequent groundings on shallow rocky rivers and streams. If only it was affordable to build a giant oven to bake a polyethylene canoe. Since that isn't an option, and I don't really want to build another mold for a kevlar and glass boat, I've been thinking of a strip build. It seems to me that the advantages of a strip canoe, especially for racers, are its ease of build for one offs, relative lightness, and its stiffness. However, the stiffness of the stressed skin design with thin skins does not translate well to impact resistance. Typically constructed with a lightweight and thick core, the stressed skin design is easy punctured and the core has little compression strength once one of the skins is compromised or the impact forces the skin into the much weaker core. When grounding out with my kevlar/glass boats I can watch and feel the hull flex over the load, with little apparent ill effects as it spreads the stress out over a larger and more flexible area than a cored boat is capable of.

So, my hypothesis is, why not use a thinner yet more dense and stronger core material that acts as less of a core and more of a functional part of the laminate (I understand that cedar already does this over a foam core). Western red cedar's weakness is its lack of hardness or its susceptibility to denting upon impact. The wood species most readily available to me (Kansas/Missouri) are white oak and black walnut. White oak is about twice the price of western red cedar, walnut is much more expensive, but since I would be using much less material with a denser wood (1/8" strips vs 1/4" for the same weight) the price difference becomes much less. Kerf waste from the saw becomes the driving factor between the price points.

With a thinner core, more flexibility would be retained to spread out the impact loads similar to a non cored composite (like a Millbrook). Final weight should come out similar or lighter depending on wood species and strip thickness. The concentrated point impact resistance, such as grounding out on a rock or gravel, becomes much greater with more dense wood and should reduce delamination between skin and core.

After all that, my question for everyone is why do we build such stiff canoes when most of us are not racers, and as trippers or recreationalists (mixed water, rivers/shallows, open water secondary specific) overall durability and lightness would seem to be more important? If a non cored composite canoe is the most durable per weight on a river why do we build on such less emphasis of survivability when considering the paddling environment. Hopefully Stripperguy, our resident materials engineer, can enlighten me on the engineering details.

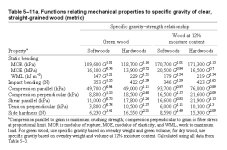

Not, sure if this will work, but I will attempt to add a spreadsheet of the material properties of the woods I'm discussing. Looking at the numbers it seems that these species would be suitable in thinner strips as long as the overall weight was kept the same. [TABLE="border: 0, cellpadding: 0, cellspacing: 0"]

[TR]

[TD]Species[/TD]

[TD]Moisture Content[/TD]

[TD]Specific Gravity[/TD]

[TD]Modulus of rupture (kPa)[/TD]

[TD]Modulus of elasticity (Mpa)[/TD]

[TD]Work to maximum load (kj m[SUP]-3[/SUP])[/TD]

[TD]Impact bending (mm)[/TD]

[TD]Compression parallel to grain (kPa)[/TD]

[TD]Compression perpendicular to grain (kPa)[/TD]

[TD]Shear parallel to grain (kPa)[/TD]

[TD]Tension perpendicular to grain (kPa)[/TD]

[TD]Side hardness (N)[/TD]

[/TR]

[TR]

[TD]Oak (Bur)[/TD]

[TD]12%[/TD]

[TD]0.64[/TD]

[TD]71,000[/TD]

[TD]7,100[/TD]

[TD]68[/TD]

[TD]740[/TD]

[TD]41,800[/TD]

[TD]8,300[/TD]

[TD]12,500[/TD]

[TD]4,700[/TD]

[TD]6,100[/TD]

[/TR]

[TR]

[TD]Oak (White)[/TD]

[TD]12%[/TD]

[TD]0.68[/TD]

[TD]105,000[/TD]

[TD]12,300[/TD]

[TD]102[/TD]

[TD]940[/TD]

[TD]51,300[/TD]

[TD]7,400[/TD]

[TD]13,800[/TD]

[TD]5,500[/TD]

[TD]6,000[/TD]

[/TR]

[TR]

[TD]Walnut (Black)[/TD]

[TD]12%[/TD]

[TD]0.55[/TD]

[TD]101,000[/TD]

[TD]11,600[/TD]

[TD]74[/TD]

[TD]860[/TD]

[TD]52,300[/TD]

[TD]7,000[/TD]

[TD]9,400[/TD]

[TD]4,800[/TD]

[TD]4,500[/TD]

[/TR]

[TR]

[TD]Cedar (Western Red)[/TD]

[TD]12%[/TD]

[TD]0.32[/TD]

[TD]51,700[/TD]

[TD]7,700[/TD]

[TD]40[/TD]

[TD]430[/TD]

[TD]31,400[/TD]

[TD]3,200[/TD]

[TD]6,800[/TD]

[TD]1,500[/TD]

[TD]1,600[/TD]

[/TR]

[/TABLE]

This has got me thinking of the most common problem I deal with. How do I build a canoe that can handle frequent groundings on shallow rocky rivers and streams. If only it was affordable to build a giant oven to bake a polyethylene canoe. Since that isn't an option, and I don't really want to build another mold for a kevlar and glass boat, I've been thinking of a strip build. It seems to me that the advantages of a strip canoe, especially for racers, are its ease of build for one offs, relative lightness, and its stiffness. However, the stiffness of the stressed skin design with thin skins does not translate well to impact resistance. Typically constructed with a lightweight and thick core, the stressed skin design is easy punctured and the core has little compression strength once one of the skins is compromised or the impact forces the skin into the much weaker core. When grounding out with my kevlar/glass boats I can watch and feel the hull flex over the load, with little apparent ill effects as it spreads the stress out over a larger and more flexible area than a cored boat is capable of.

So, my hypothesis is, why not use a thinner yet more dense and stronger core material that acts as less of a core and more of a functional part of the laminate (I understand that cedar already does this over a foam core). Western red cedar's weakness is its lack of hardness or its susceptibility to denting upon impact. The wood species most readily available to me (Kansas/Missouri) are white oak and black walnut. White oak is about twice the price of western red cedar, walnut is much more expensive, but since I would be using much less material with a denser wood (1/8" strips vs 1/4" for the same weight) the price difference becomes much less. Kerf waste from the saw becomes the driving factor between the price points.

With a thinner core, more flexibility would be retained to spread out the impact loads similar to a non cored composite (like a Millbrook). Final weight should come out similar or lighter depending on wood species and strip thickness. The concentrated point impact resistance, such as grounding out on a rock or gravel, becomes much greater with more dense wood and should reduce delamination between skin and core.

After all that, my question for everyone is why do we build such stiff canoes when most of us are not racers, and as trippers or recreationalists (mixed water, rivers/shallows, open water secondary specific) overall durability and lightness would seem to be more important? If a non cored composite canoe is the most durable per weight on a river why do we build on such less emphasis of survivability when considering the paddling environment. Hopefully Stripperguy, our resident materials engineer, can enlighten me on the engineering details.

Not, sure if this will work, but I will attempt to add a spreadsheet of the material properties of the woods I'm discussing. Looking at the numbers it seems that these species would be suitable in thinner strips as long as the overall weight was kept the same. [TABLE="border: 0, cellpadding: 0, cellspacing: 0"]

[TR]

[TD]Species[/TD]

[TD]Moisture Content[/TD]

[TD]Specific Gravity[/TD]

[TD]Modulus of rupture (kPa)[/TD]

[TD]Modulus of elasticity (Mpa)[/TD]

[TD]Work to maximum load (kj m[SUP]-3[/SUP])[/TD]

[TD]Impact bending (mm)[/TD]

[TD]Compression parallel to grain (kPa)[/TD]

[TD]Compression perpendicular to grain (kPa)[/TD]

[TD]Shear parallel to grain (kPa)[/TD]

[TD]Tension perpendicular to grain (kPa)[/TD]

[TD]Side hardness (N)[/TD]

[/TR]

[TR]

[TD]Oak (Bur)[/TD]

[TD]12%[/TD]

[TD]0.64[/TD]

[TD]71,000[/TD]

[TD]7,100[/TD]

[TD]68[/TD]

[TD]740[/TD]

[TD]41,800[/TD]

[TD]8,300[/TD]

[TD]12,500[/TD]

[TD]4,700[/TD]

[TD]6,100[/TD]

[/TR]

[TR]

[TD]Oak (White)[/TD]

[TD]12%[/TD]

[TD]0.68[/TD]

[TD]105,000[/TD]

[TD]12,300[/TD]

[TD]102[/TD]

[TD]940[/TD]

[TD]51,300[/TD]

[TD]7,400[/TD]

[TD]13,800[/TD]

[TD]5,500[/TD]

[TD]6,000[/TD]

[/TR]

[TR]

[TD]Walnut (Black)[/TD]

[TD]12%[/TD]

[TD]0.55[/TD]

[TD]101,000[/TD]

[TD]11,600[/TD]

[TD]74[/TD]

[TD]860[/TD]

[TD]52,300[/TD]

[TD]7,000[/TD]

[TD]9,400[/TD]

[TD]4,800[/TD]

[TD]4,500[/TD]

[/TR]

[TR]

[TD]Cedar (Western Red)[/TD]

[TD]12%[/TD]

[TD]0.32[/TD]

[TD]51,700[/TD]

[TD]7,700[/TD]

[TD]40[/TD]

[TD]430[/TD]

[TD]31,400[/TD]

[TD]3,200[/TD]

[TD]6,800[/TD]

[TD]1,500[/TD]

[TD]1,600[/TD]

[/TR]

[/TABLE]

Last edited: