G

Guest

Guest

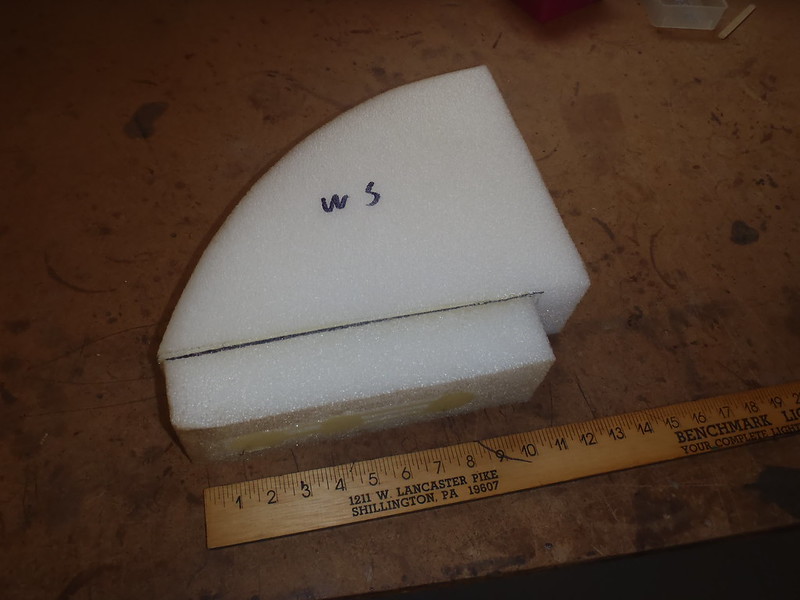

The Wenonah Wilderness still lacked a couple of handy outfitting touches.

Most importantly, an in camp storage cover over the open center between the partial spray covers, so I can leave all the paddling gear inside and dry while in camp.

Some sizing and design play with a piece of Tyvek, well whadda ya know, the best coverage and riveted stud placement on the hull can be achieved with a simple 68 x 34 inch rectangle and five strategic studs on each side.

P3090605 by Mike McCrea, on Flickr

P3090605 by Mike McCrea, on Flickr

P3090608 by Mike McCrea, on Flickr

P3090608 by Mike McCrea, on Flickr

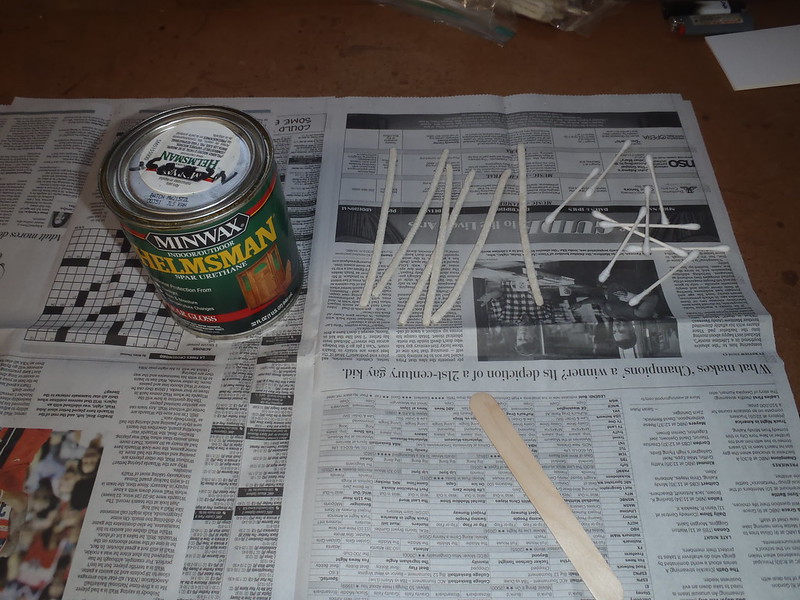

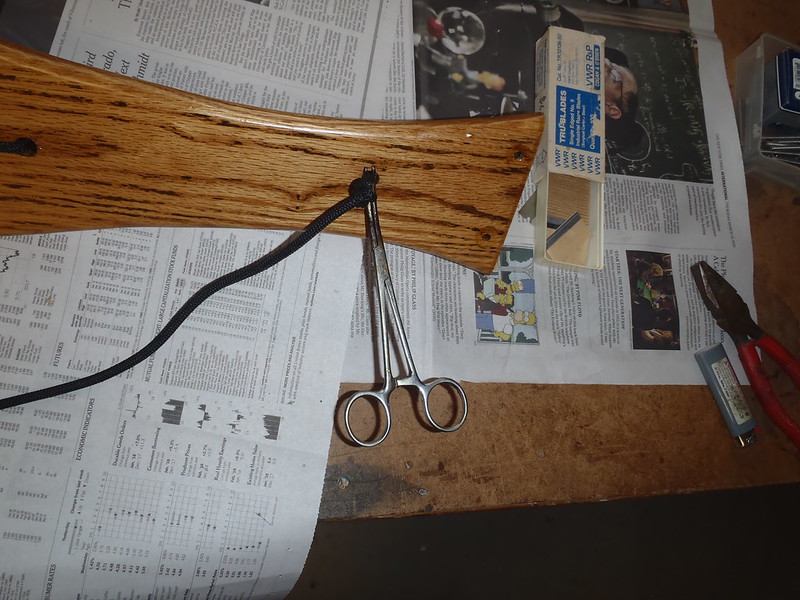

Once you have a modified pop rivet gun and some practice installing snap rivets that is some easy peezy work that takes only minutes, and I have added snaps to make other gear more functional.

Tape the cover fitted in place, stick a multi-layer length of duct tape on the hull below a cover snap and press to make an indentation in the duct tape. My eyes are weak, so I Sharpie dot the center of the impressed stud ring so my drilling aim is true. Or not the center, sometimes the blind aim and press for indentation into tape is a bit off from best placement, and I can adjust that with the Sharpie drilling dot.

Drill the hole. And remember to take the duct tape off before you rivet the stud in place. That oops did not occur this time, but has in the past. Eh, more than once.

P3090603 by Mike McCrea, on Flickr

P3090603 by Mike McCrea, on Flickr

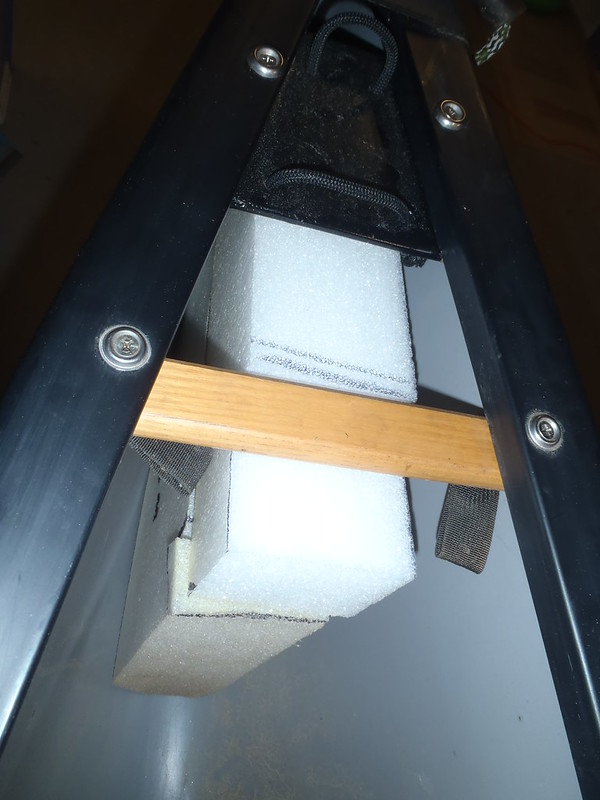

For ease of installation all three pieces are marked for bow or stern orientation.

P3100616 by Mike McCrea, on Flickr

P3100616 by Mike McCrea, on Flickr

It all still fits in the bag with room to spare.

P3100617 by Mike McCrea, on Flickr

P3100617 by Mike McCrea, on Flickr

I do like having a fully covered canoe in camp.

Most importantly, an in camp storage cover over the open center between the partial spray covers, so I can leave all the paddling gear inside and dry while in camp.

Some sizing and design play with a piece of Tyvek, well whadda ya know, the best coverage and riveted stud placement on the hull can be achieved with a simple 68 x 34 inch rectangle and five strategic studs on each side.

P3090605 by Mike McCrea, on Flickr

P3090605 by Mike McCrea, on Flickr P3090608 by Mike McCrea, on Flickr

P3090608 by Mike McCrea, on FlickrOnce you have a modified pop rivet gun and some practice installing snap rivets that is some easy peezy work that takes only minutes, and I have added snaps to make other gear more functional.

Tape the cover fitted in place, stick a multi-layer length of duct tape on the hull below a cover snap and press to make an indentation in the duct tape. My eyes are weak, so I Sharpie dot the center of the impressed stud ring so my drilling aim is true. Or not the center, sometimes the blind aim and press for indentation into tape is a bit off from best placement, and I can adjust that with the Sharpie drilling dot.

Drill the hole. And remember to take the duct tape off before you rivet the stud in place. That oops did not occur this time, but has in the past. Eh, more than once.

P3090603 by Mike McCrea, on Flickr

P3090603 by Mike McCrea, on FlickrFor ease of installation all three pieces are marked for bow or stern orientation.

P3100616 by Mike McCrea, on Flickr

P3100616 by Mike McCrea, on FlickrIt all still fits in the bag with room to spare.

P3100617 by Mike McCrea, on Flickr

P3100617 by Mike McCrea, on FlickrI do like having a fully covered canoe in camp.