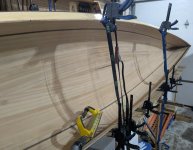

It's looking good! I imagine that planing down the inner stem like that could be a real hassle depending on grain and what tools you have available. For sanding it's hard to beat that random orbital though! I had the pleasure of borrowing the larger festool random orbital (with a 8" pad or something in that ballpark) a few years ago, and I've never had an easier time of a tough sanding job.

Out of my budget at the moment but boy... if you're looking down the barrel of a bunch of sanding and have the $$$ they are amazing!

Out of my budget at the moment but boy... if you're looking down the barrel of a bunch of sanding and have the $$$ they are amazing!