The tape reveal

The funnest part of a taping and painting extravaganza is finally pulling the tape.

All of the tape, and there was a lot to pull; tape wrapped around the gunwales, tape 5” below the gunwales and tape surrounding accent diamonds.

Yay, I had thoughtfully laid all of the tapes in strategic order, all with folded over pull tabs on one end.

One other trick to it, the tape on the gunwales had four coats of paint, two coats green hull and two coats white stripe, all gravity fed sealing the edge of the tape to inwale edge. I ran an Exacto knife between the hull and gunwale edge to help free the tape.

Well, ok, I briefly tried to peel off the gunwale tape - egads, it was shredding within inches - before going to the Plan B Exacto blade. With the Exacto slice 99% of the gunwale tape came off cleanly, with just a few stubborn scraps.

P6190001

P6190001 by

Mike McCrea, on Flickr

Dang, what a difference a couple coats of paint can make.

YARR still needed a few decorative white stripe touches. On the bow YARR needed YARR.

P6190004

P6190004 by

Mike McCrea, on Flickr

And, as balance on the other side, a Duckhead sticker. Nothing could be more Duckhead than a 1984 freebie canoe rebuilt twice. And of course there is a Duckhead sticker on OOSOBO. This matching canoe paint scheme and sticker décor has got to catch the eye of a curious reservoir cop at the launches.

P6190006

P6190006 by

Mike McCrea, on Flickr

On the right stern, where it should be, a stainless steel HIN tag, with homage to the original pre-rebuild.

P6190009

P6190009 by

Mike McCrea, on Flickr

BTW, once again I see in photos things I missed in person; I filled in the missing white under the deck plates with a small brush, actually OCD touched up any sliver of missing white along the outwale edges. Five minutes to touch up the under-gunwale holidays on both sides; I’m running out of YARR tasks.

And still making “mistakes”. I had three lines of text to available on that SS tag, I really should have included another historic line, “

Das Uber Bot”. Tom told me the wording of the mostly vanished subtext line, but it was an esoteric Tom-ism; something like “

Taking submarined canoeing to new low”, in honor of finishing some drops upside down.

While the alcohol spray bottle was out for stickers I found that I had a couple feet of green High Intensity reflective tape left, nearly the last of that discontinued tape. 3” pieces with rounded ends bow and stern; I didn’t want to crowd the white stripe, so adhered the tape just below where the green begins.

P6190012

P6190012 by

Mike McCrea, on Flickr

Without the camera flash that green-on-green tape is barely visible, but hit with a flashlight it winks back bright at night. It’s nice to be able to flash a light and see the canoe, or canoes, beam back. Our family trippers have different tape patterns, so I can flash a light and see four distinct tape arrangements wink back. Even with a single canoe, just checking.

P3070819

P3070819 by

Mike McCrea, on Flickr

The reflective stem tape also leads to less noggin bumping on the stern overhang in dark campgrounds and parking lots. Possibly a dusk capsize or lost boat help as well.

For symmetry YARR needed some flourish on the left stern to complement the HIN tag. As on OOSOBO another distinctive identifier, the traditional Shop Gogetch, indicating that this boat was refurbished under several moon phases, with a pipe phase or two, and a few IPA phases.

A small Shop Gogetch, traced on the hull with carbon paper, and as usual I called in the artist in residence to do the actual paint-by-numbers fill in.

P6200015

P6200015 by

Mike McCrea, on Flickr

That is the smallest Gogetch yet, 3” x 4”. He has the patience and steady hand to do fine brushwork.

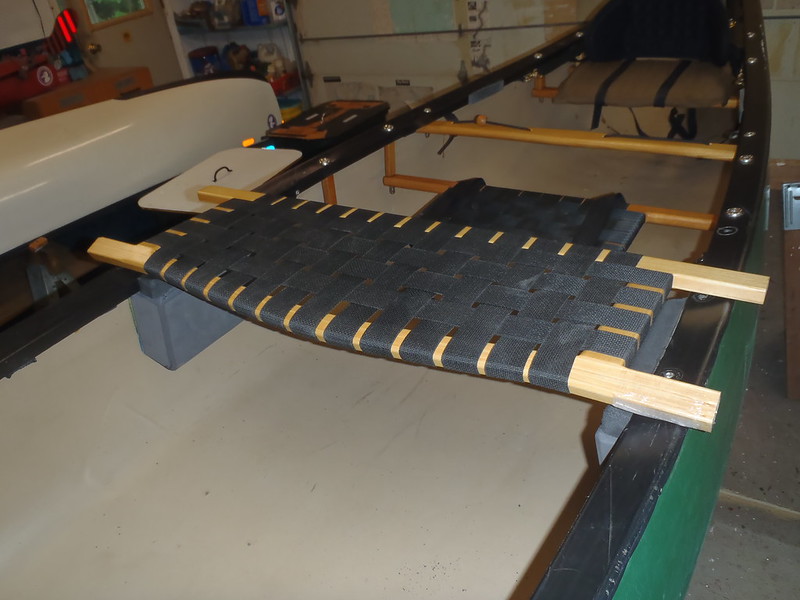

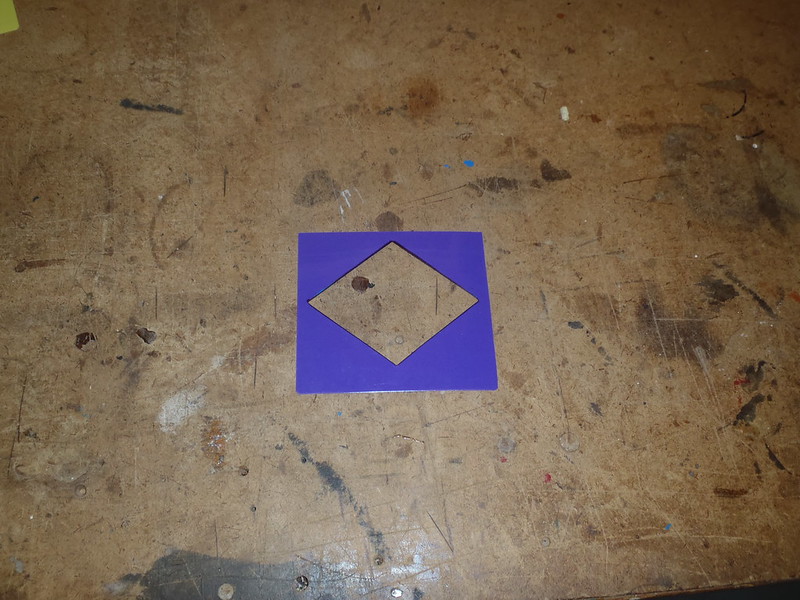

With YARR held sideways I had opportunity to install the customized flanges in the old ¾” hawser holes.

P6200018

P6200018 by

Mike McCrea, on Flickr

A little G/flex, a little wax paper cover, sandbag weight on the flanges, and it was again walk-away time. Those gaping holes looked much better with black flanges.

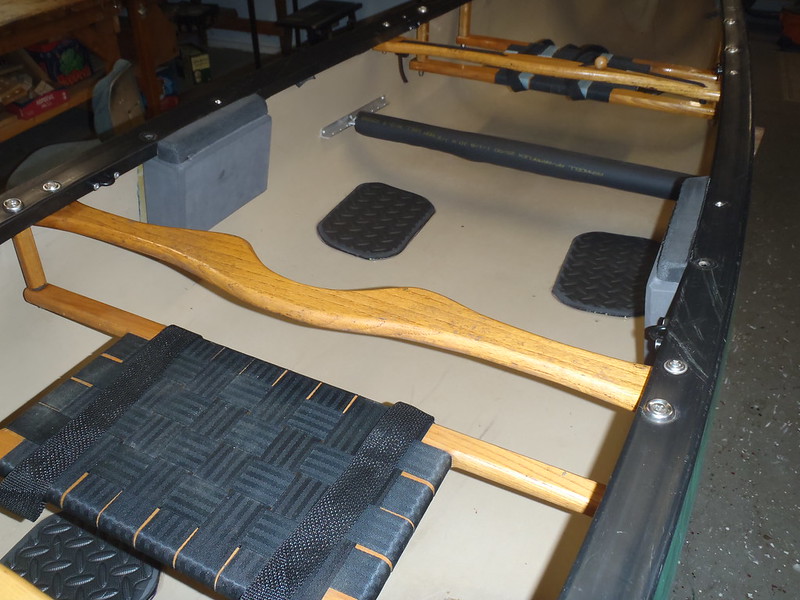

P6200022

P6200022 by

Mike McCrea, on Flickr

Flip YARR 180 degrees and do the flanges on other side. I made enough extra G/flex to belt and suspenders swipe some inside the hull on the slightly protruding flange necks. Those conduit adapters are not going anywhere.

It is always a good idea to prep things for any leftover G/flex, I removed the wing nutted yoke to lay an epoxy bead around the edge of the countersink, and prep-cleaned the Missus favorite sandals, which had become loose soled tripper flappers.

P6210024

P6210024 by

Mike McCrea, on Flickr

Done, barely a drop of G/flex left. Into the trash with the medicine cup and brush. And back out of the trash; I had forgotten about the fender washers on the yoke. I wasn’t making for G/flex for something destined to be used twice a year. Wringing the dregs out of the pot and tiny brush the fender washers got more of a smear than a bead. Don’t care, it’s the bottom of something that will get used twice a year.

Once that flange epoxy set up YARR got painter line loops, with the usual bicycle handlebar toggle grips.

P6220029

P6220029 by

Mike McCrea, on Flickr

P6220030

P6220030 by

Mike McCrea, on Flickr

Uh, oh, I see a major mistake. There is nothing left to do on YARR, and summer has just begun. Guess I need to find another rebuild project soon.