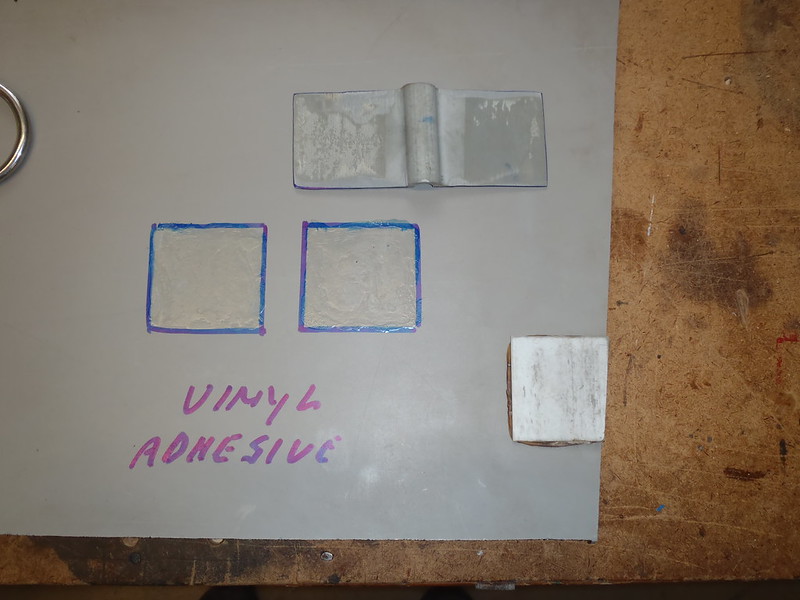

Another shelter-in-place day of cinderblock hositing. The rigid plastic pad D-rings, one adhered with Vynabond and the other with G/flex, have had a week to cure, and the horribly sloppy DIY webbing, glass tape and epoxy D-ring likewise.

P4100016 by

Mike McCrea, on Flickr

That DIY D-ring attachment would have looked much neater had I just tape boxed a perimeter a bit beyond the fiberglass tape instead of just smearing the epoxy on. And not used old (not even that old), already getting dark 205 Fast hardener. The pump was cleaned and replaced 4/19, and the can of 205 isn’t much older.

P4100017 by

Mike McCrea, on Flickr

Those DIY D-rings need not look as ugly

P4110041 by

Mike McCrea, on Flickr

My resins and hardeners are kept relatively temperature-stable, typically between a low of 50-55f and max of 75-80F. I have no use for West System Fast hardener anymore; I’m slow in the shop, and that stuff goes dark too fast.

The Vynabond pad failed faster that I would have thought, popping off the Royalex sheet pad fully intact at 127.5lbs. With zero wait time, add the last weight, jump-back-Jack and watch your toes, so maybe less weight. I’m guessing that the hard plastic pad is not vinyl. Nylon maybe? Vynabond on that hard plastic pad sucked, and I never like that pad style D-ring in any case.

P4100028 by

Mike McCrea, on Flickr

Next, the G/flexed hard plastic D-ring pad.

P4100019 by

Mike McCrea, on Flickr

Eeek, something made a sharp CRACK sound at 119 lbs. That is a sheet of probably brittle Royalex from an ancient Dagger Caper. Something cracked, but it is still hanging together.

It was not, as I suspected, cracked RX; some underside inspection showed that the rigid plastic D-ring pad had started to separate from the Royalex at one end. That RX sheet had a slight arch to it, and with 119lb on the RX went decidedly flat between the two 4x4s. The rigid plastic pad, which had been weighted down to the slight curve as the epoxy cured, did not like that action.

P4100022 by

Mike McCrea, on Flickr

Still holding on at 187.5lbs

P4100024 by

Mike McCrea, on Flickr

The pad finally failed at 226lbs. Actually the pad didn’t fail; the Royalex sheet didn’t break in half between the 4x4’s and the D-ring was still perfect; the hard plastic pad again popped free, taking a bit of Royalex skin with it

Those hard plastic pads were bought decades ago when the Keelhauler’s outfitter went out of business. I actually had those installed in a canoe which I later rebuilt. I don’t recall what adhesive I originally used, probably Vynabond, but on the rebuild those hard pad D-rings popped off when I have them a good hard tug.

I ran the bottoms of those old plastic pads on a 4x36 tabletop sander to take off any adhesive residue, so they were actually a bit thinner and more flexible than original plastic pads. I again kept them, and may sand of the new residue, but I’ll never use them in a boat again.

I could sand the residue off the bottom of the surprisingly clean Vynabond pad and try it with contact cement, but I know (ok, I

think, at this point half the stuff I thought I

knew I now know better) that contact cement would provide a much weaker bond.

I am left thinking that the flexibility of vinyl pad D-rings has distinct advantages over the rigid plastic pads when the hull flexes. I do still wonder about how much weight the stitching in those sewn D-ring pads will support, but that is another

we’ll never know.

Last test piece, the fugly FIY D-ring with webbing, glass tape and epoxy.

P4100029 by

Mike McCrea, on Flickr

The DIY D-ring made a couple of faint crack sounds at 119lbs as the arched RX sheet flattened out and I left it to hang for a while. A long while, getting really tired of re-positioning cinderblocks, which I now refer to as F%#&@*! cinder blocks, and it was time for a beer.

More cracking sounds at 157.5lb, and the occasional snap-crackle-pop resounded through the shop for a few minutes. More weight added, still holding, but making near constant cracking sounds for 10 minutes later before quieting down.

Er, no, as I finished my beer it started cracking, even more loudly and more frequently. It’s gonna break any minute now.

Scotty, we need more power!

“She can’t take much more Captain”.

She could, but at 187.5lbs the cracking sounds got louder and louder, and more frequent, and I kept my distance.

P4110031 by

Mike McCrea, on Flickr

Still held for a few minutes of snap-crackle-pop before the 187.5lb crash.

The West 105/205 saturated poly webbing and glass tape pulled cleanly off the hull. The metal D-ring itself is still fine and I cut it off for (?) future use.

P4110038 by

Mike McCrea, on Flickr

That DIY D-ring might have held better had I propane torch flamed the RX first. Almost certainly would have held better had I used G/flex (note “flex” in the description) as the epoxy.

Dammit, I

really want to try a vinyl pad D-ring. Or vinyl pad D-rings plural, one with installed with Vynabond and one with Gflex. Or plural X4, vinyl pads with stainless steel vs nylon D rings. Or X6 if I test vinyl pads with sewn in webbing loops instead of D-rings.

Maybe after I hit the Lotto and can blow my winnings on an assortment of vinyl D-ring pads. I really like Northwater’s nylon double D’s for running two straps in different directions, and have those in most canoes. I would like to know what fails how at what weight.

I’m moving all the weight testing folderol back outside today – oh boy, more F%#&@*! cinder blocks to carry around – and cleaning the busted pieces off the shop floor. But somehow I’m not sure I’m done with this experiment just yet.