Here I go again !

I thought I would settle back, and spend more time paddling, than building.

All of a sudden, materials started falling into my lap.

Picked at least 20yds, of 5 oz x 50" Kevlar, at an auction for $5.

Then a bunch of WRC trimmings from a local supplier, grabbed my attention. Most of it was, 3/4"x 1 5/8"x 8'. It was mostly clear, and flat grain. I try and shy way from less than full length strips, but for the price ? I couldn't pass it up ! Enough wood for about three hulls. They gave it to me ! Once I made it back to the shop, and started looking it over ! I felt like a Thief, and went back with $100 . I slept a lot better after that !

To start the project, I Cut strips on the Shop's Delta Unisaw. This was going to be my first hull, using 3/16" strips. As it turns out ? The Unisaw with a gang of three Freud Diablo blades, yielded 6 strips making only 2 passes, Perfect !.

I know a few are saying " No Skilsaw ? " In this case the Unisaw reigned as King !

It took a lot of trial and error, but with enough washers, and Dado blade spacers, I was able to get all the strips the same thickness.

Now for bead and cove. I used the same bits I use for 1/4" thick strips. It worked, but next time, I'll go with 3/32" radius bits.

I'll throw in some picks. I started this build at the Nokomis Wood shop, last Fall. The Shop, was given access to more work space. It was just Begging for me to build a canoe in !

After playing with the fence, I discovered that moving the fence back towards me, I achieved a cleaner cut at the tail of the planks.

Saw was set.

Made some push handles, to keep me safe, and planks against the fence.

Here's a pick of the set up. I didn't use any feather boards. It worked fine, but next time I will set feathers !

More later.

I thought I would settle back, and spend more time paddling, than building.

All of a sudden, materials started falling into my lap.

Picked at least 20yds, of 5 oz x 50" Kevlar, at an auction for $5.

Then a bunch of WRC trimmings from a local supplier, grabbed my attention. Most of it was, 3/4"x 1 5/8"x 8'. It was mostly clear, and flat grain. I try and shy way from less than full length strips, but for the price ? I couldn't pass it up ! Enough wood for about three hulls. They gave it to me ! Once I made it back to the shop, and started looking it over ! I felt like a Thief, and went back with $100 . I slept a lot better after that !

To start the project, I Cut strips on the Shop's Delta Unisaw. This was going to be my first hull, using 3/16" strips. As it turns out ? The Unisaw with a gang of three Freud Diablo blades, yielded 6 strips making only 2 passes, Perfect !.

I know a few are saying " No Skilsaw ? " In this case the Unisaw reigned as King !

It took a lot of trial and error, but with enough washers, and Dado blade spacers, I was able to get all the strips the same thickness.

Now for bead and cove. I used the same bits I use for 1/4" thick strips. It worked, but next time, I'll go with 3/32" radius bits.

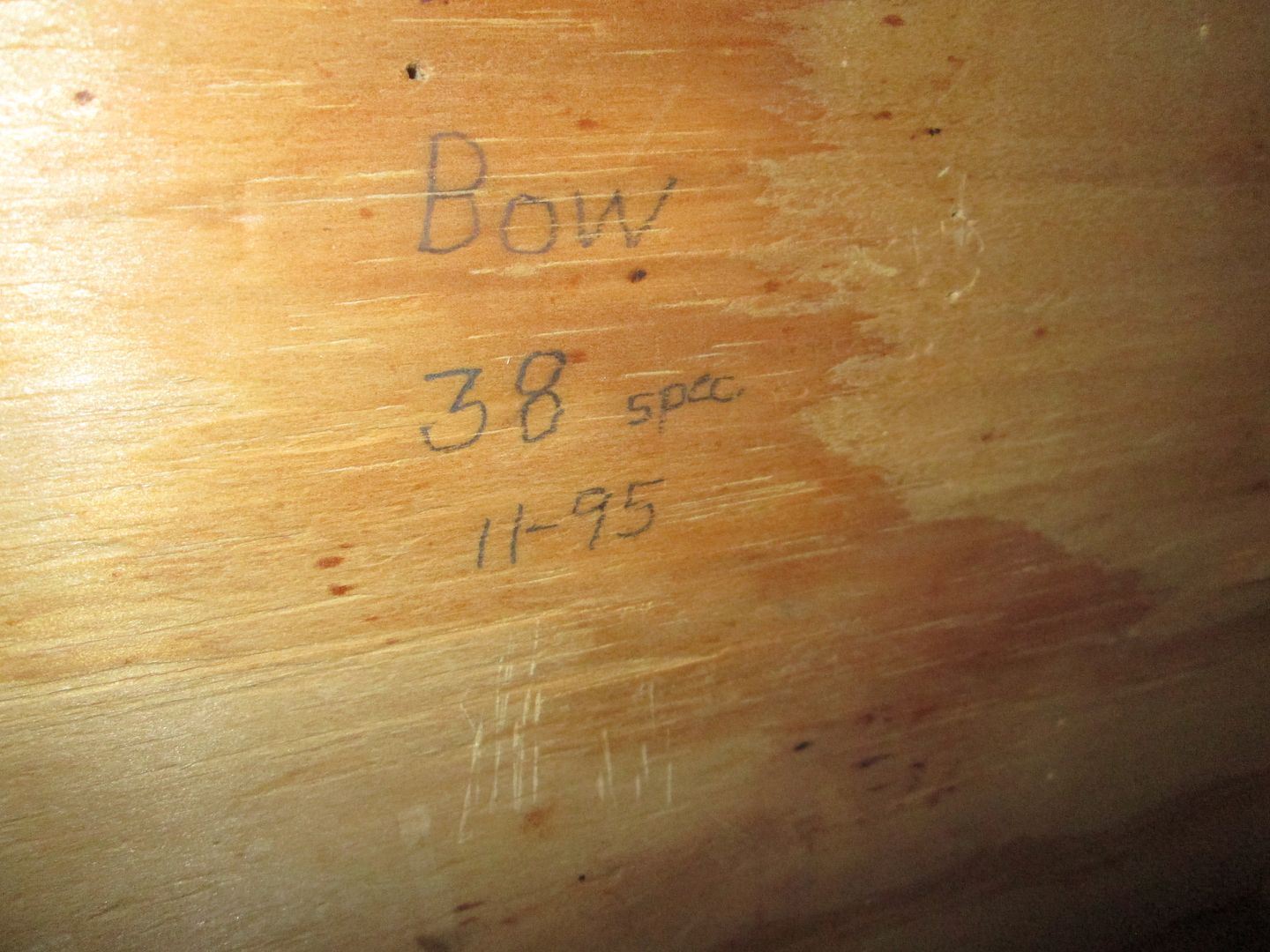

I'll throw in some picks. I started this build at the Nokomis Wood shop, last Fall. The Shop, was given access to more work space. It was just Begging for me to build a canoe in !

After playing with the fence, I discovered that moving the fence back towards me, I achieved a cleaner cut at the tail of the planks.

Saw was set.

Made some push handles, to keep me safe, and planks against the fence.

Here's a pick of the set up. I didn't use any feather boards. It worked fine, but next time I will set feathers !

More later.