I have a short trip planned for mid October, and, there's an unknown amount of carrying where there are no trails.

I have an old portage thwart from one of my builds from 1984, it used to be a pretty cedar laminate, that fit my 30 year old physique perfectly.

Well, I ain't 30 any more, and that thwart ain't so pretty either.

Of late, I have been strapping it to whichever boat I happen to be carrying. Oh, it's ugly, a pair of deck screws jammed into the ends of the too wide thwart. It was slow to attach, prone to shifting, and slow to remove and stow until the next use.

Anyway, I figured I should at least improve the attachment somewhat. I can't discard the thwart, there's too many miles and too many memories attached to it...

My most recent builds have carbon fiber over foam gunnels, so I needed to add a couple of "lumps" to the gunnels, to allow some sort of fastener to hold the portage thwart in place.

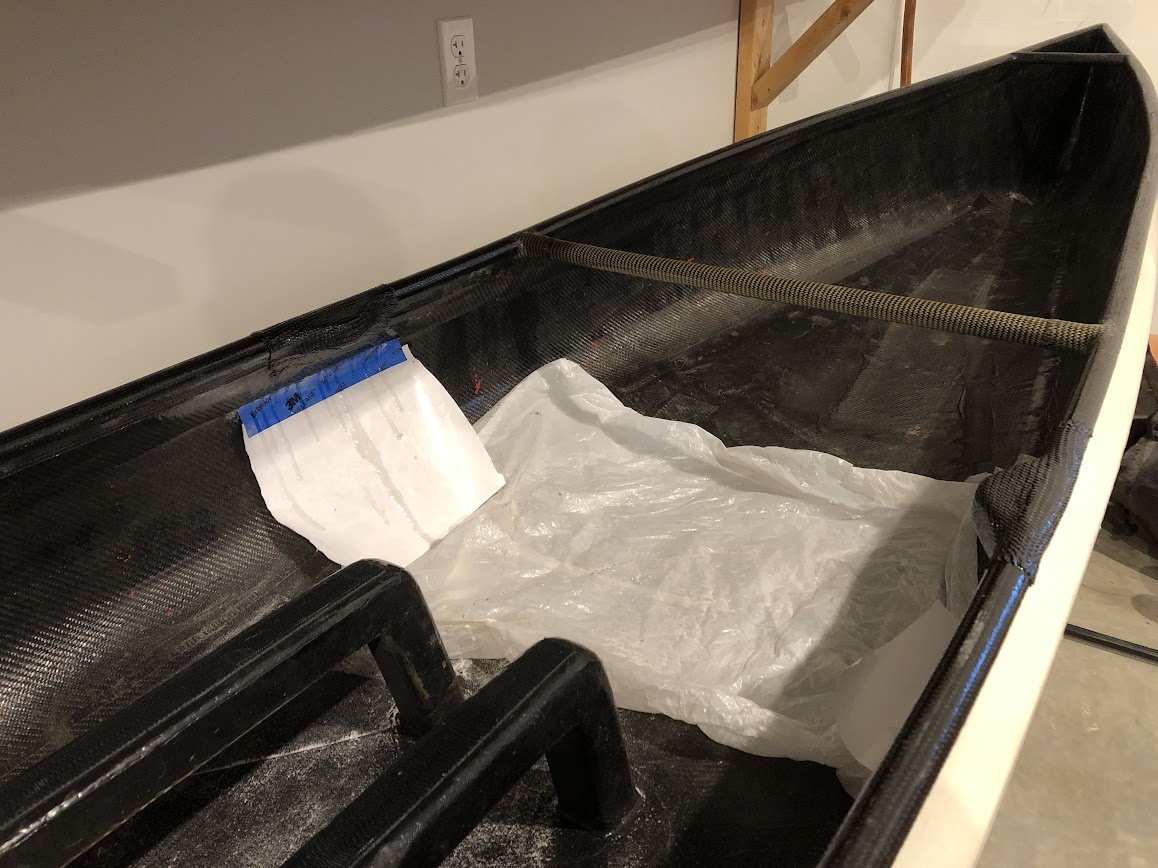

Here's where I started, 3 small pieces of 3/8" thick H80 Divinycell, epoxied together. This pic shows the 3 pieces partially shaped to fit the inside of the gunnels.

Here's how the lump will fit, you can see it needs a bit more shaping to match the gunnel.

Then, after I adhered the lumps with Cabosil thickened epoxy, it was a quick wet out with some left over bias woven carbon tape.

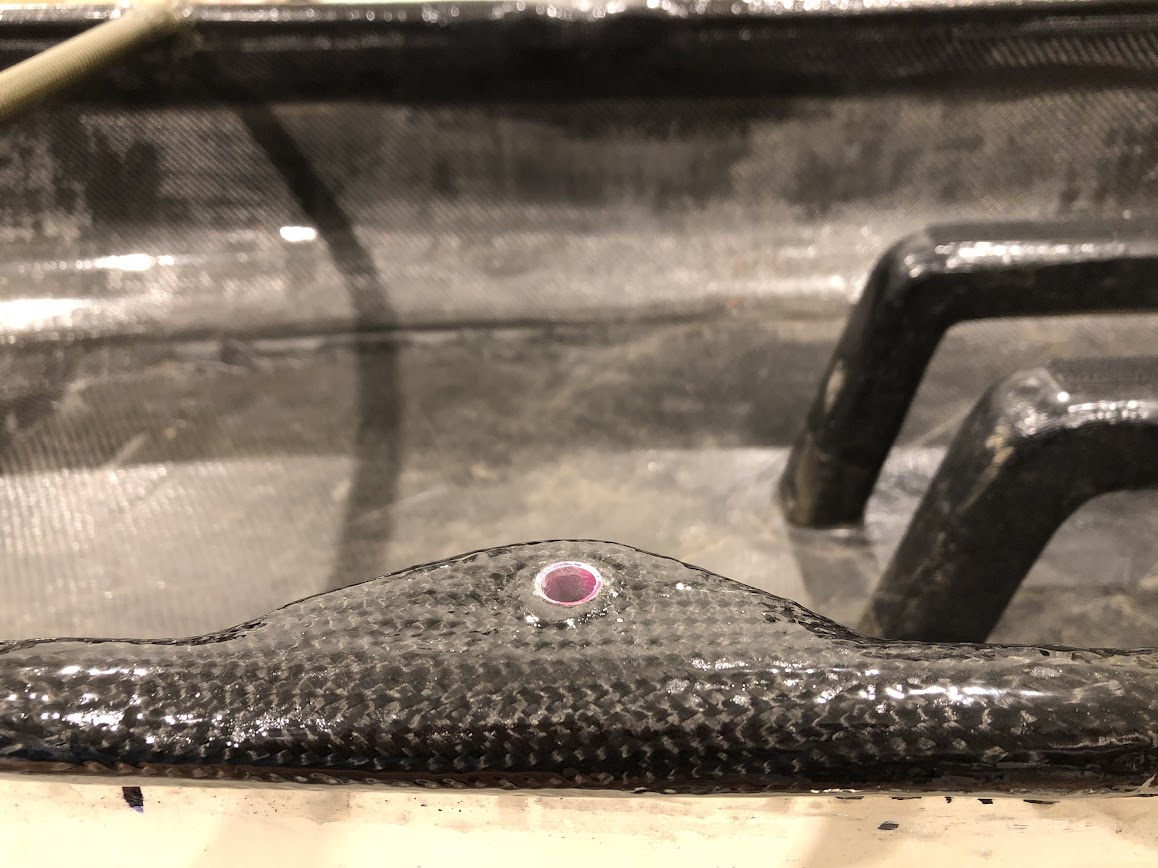

After several iterations of sanding and filling, I drilled a 17/32" hole, and epoxied in a short piece of 1/2" OD aluminum tube (that you can see), and a 1/4"-20 nutsert in the bottom side (that you can't see).

You can see I'm almost finished, just needs a little more sand and fill. One more iteration should do it.

So all that needs to be done (except for the last bit of sand and fill) is to remove those fugly deck screws, drill a couple holes, purchase a couple 1/4-20 knobs, and sand and seal my faithful thwart.

All in all just a few hours effort, spread over a few days...what took me so long??? I should have done this years ago!!

I have an old portage thwart from one of my builds from 1984, it used to be a pretty cedar laminate, that fit my 30 year old physique perfectly.

Well, I ain't 30 any more, and that thwart ain't so pretty either.

Of late, I have been strapping it to whichever boat I happen to be carrying. Oh, it's ugly, a pair of deck screws jammed into the ends of the too wide thwart. It was slow to attach, prone to shifting, and slow to remove and stow until the next use.

Anyway, I figured I should at least improve the attachment somewhat. I can't discard the thwart, there's too many miles and too many memories attached to it...

My most recent builds have carbon fiber over foam gunnels, so I needed to add a couple of "lumps" to the gunnels, to allow some sort of fastener to hold the portage thwart in place.

Here's where I started, 3 small pieces of 3/8" thick H80 Divinycell, epoxied together. This pic shows the 3 pieces partially shaped to fit the inside of the gunnels.

Here's how the lump will fit, you can see it needs a bit more shaping to match the gunnel.

Then, after I adhered the lumps with Cabosil thickened epoxy, it was a quick wet out with some left over bias woven carbon tape.

After several iterations of sanding and filling, I drilled a 17/32" hole, and epoxied in a short piece of 1/2" OD aluminum tube (that you can see), and a 1/4"-20 nutsert in the bottom side (that you can't see).

You can see I'm almost finished, just needs a little more sand and fill. One more iteration should do it.

So all that needs to be done (except for the last bit of sand and fill) is to remove those fugly deck screws, drill a couple holes, purchase a couple 1/4-20 knobs, and sand and seal my faithful thwart.

All in all just a few hours effort, spread over a few days...what took me so long??? I should have done this years ago!!