And now for that seat which is finally coming together.

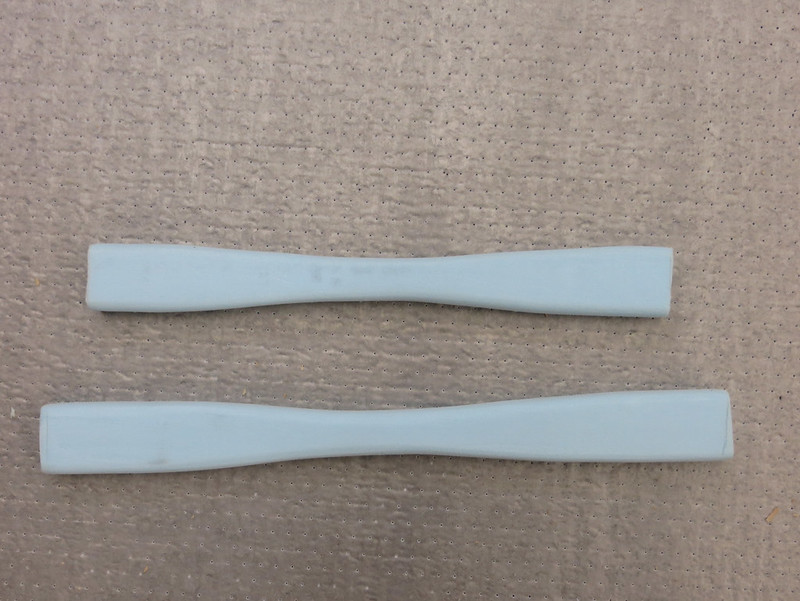

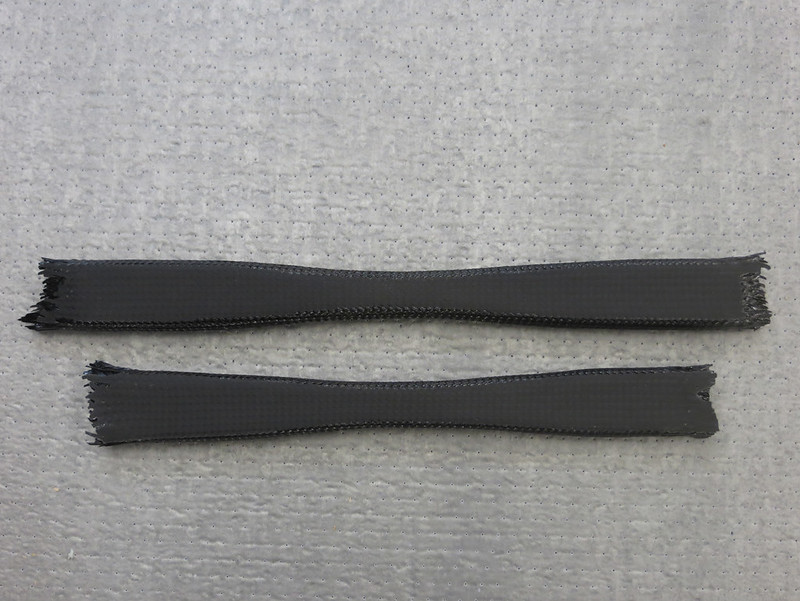

Here's the pedestal itself. The two end pieces are 3/4" foam covered with carbon and the webs are 1/4" carboned foam. I added some small wood blocks so I'd have something to screw into and for backers to attach the webs to the ends. The aluminum tubing is 1"

20150510_008 by Alan, on Flickr

20150510_008 by Alan, on Flickr

20150510_009 by Alan, on Flickr

20150510_009 by Alan, on Flickr

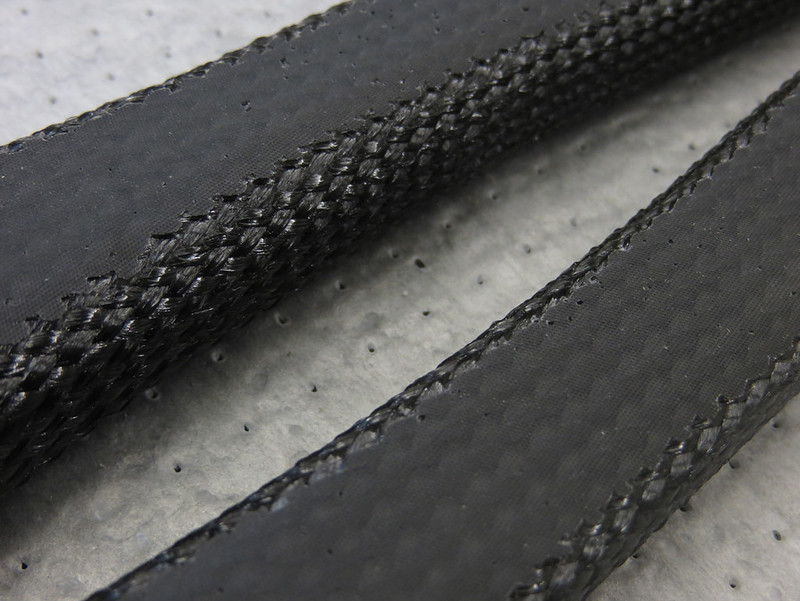

This is the bottom of the carbon seat. The white tubes that will slide over the tubes on the pedestal are 1 1/4" PVC from the hardware store (meant for bathroom vanity drains). I've used this on the last few sliders I've done and it works great. Perfect fit over the 1" aluminum and it's thin walled so light weight.

20150510_010 by Alan, on Flickr

20150510_010 by Alan, on Flickr

Adding the tubes to the seat is hard. How to hold them in place while you fasten them? The tubes that slide over the pedestal must be aligned perfectly so it doesn't bind. I've had good luck using superglue gel. Mark where the pieces go, add a dab of gel, set the tubes in place, and wait for it to setup. The superglue will hold everything in place while you add a thickened epoxy fillet and then fiberglass. Works great.

Side view of the whole assembly:

20150510_007 by Alan, on Flickr

20150510_007 by Alan, on Flickr

Forward position:

20150510_003 by Alan, on Flickr

20150510_003 by Alan, on Flickr

Rear most position:

20150510_004 by Alan, on Flickr

20150510_004 by Alan, on Flickr

20150510_005 by Alan, on Flickr

20150510_005 by Alan, on Flickr

20150510_006 by Alan, on Flickr

20150510_006 by Alan, on Flickr

I've got 7" of travel. I'll mount the seat so all the way forward will be my standard seating position, allowing me to pull my legs back for comfort without the pedestal interfering. I'll slide it back when I want to drop down and kneel or if I need to adjust trim on the fly.

It's not a thing of beauty but I think it will get the job done. The whole thing, seat included, came it at exactly 2.5 pounds. I was hoping for under 2 pounds but I'll take it. If I remember correctly the cane seats (ash) I used on my last build were 2 pounds each for just the seat.

Carbon tubing instead of aluminum would have lightened it up but I didn't have the best luck when I tried making my own.

I haven't decided if I'll paint the pedestal to match the outside of the hull or leave it plain.

Tomorrow I hope to add some fiberglass tape where the front of the float tanks meet the hull and maybe fiberglass tape over the gunwales if I get really ambitious.

Alan

Here's the pedestal itself. The two end pieces are 3/4" foam covered with carbon and the webs are 1/4" carboned foam. I added some small wood blocks so I'd have something to screw into and for backers to attach the webs to the ends. The aluminum tubing is 1"

20150510_008 by Alan, on Flickr

20150510_008 by Alan, on Flickr 20150510_009 by Alan, on Flickr

20150510_009 by Alan, on FlickrThis is the bottom of the carbon seat. The white tubes that will slide over the tubes on the pedestal are 1 1/4" PVC from the hardware store (meant for bathroom vanity drains). I've used this on the last few sliders I've done and it works great. Perfect fit over the 1" aluminum and it's thin walled so light weight.

20150510_010 by Alan, on Flickr

20150510_010 by Alan, on FlickrAdding the tubes to the seat is hard. How to hold them in place while you fasten them? The tubes that slide over the pedestal must be aligned perfectly so it doesn't bind. I've had good luck using superglue gel. Mark where the pieces go, add a dab of gel, set the tubes in place, and wait for it to setup. The superglue will hold everything in place while you add a thickened epoxy fillet and then fiberglass. Works great.

Side view of the whole assembly:

20150510_007 by Alan, on Flickr

20150510_007 by Alan, on FlickrForward position:

20150510_003 by Alan, on Flickr

20150510_003 by Alan, on FlickrRear most position:

20150510_004 by Alan, on Flickr

20150510_004 by Alan, on Flickr 20150510_005 by Alan, on Flickr

20150510_005 by Alan, on Flickr 20150510_006 by Alan, on Flickr

20150510_006 by Alan, on FlickrI've got 7" of travel. I'll mount the seat so all the way forward will be my standard seating position, allowing me to pull my legs back for comfort without the pedestal interfering. I'll slide it back when I want to drop down and kneel or if I need to adjust trim on the fly.

It's not a thing of beauty but I think it will get the job done. The whole thing, seat included, came it at exactly 2.5 pounds. I was hoping for under 2 pounds but I'll take it. If I remember correctly the cane seats (ash) I used on my last build were 2 pounds each for just the seat.

Carbon tubing instead of aluminum would have lightened it up but I didn't have the best luck when I tried making my own.

I haven't decided if I'll paint the pedestal to match the outside of the hull or leave it plain.

Tomorrow I hope to add some fiberglass tape where the front of the float tanks meet the hull and maybe fiberglass tape over the gunwales if I get really ambitious.

Alan