- Joined

- Jul 6, 2021

- Messages

- 643

- Reaction score

- 563

Look what followed me home from Lancaster, another Hyperform Lettmann Optima. My current Optima came out of Lancaster County; someone up that way was selling Hyperform in the ‘70’s.

P8300001 by Mike McCrea, on Flickr

P8300001 by Mike McCrea, on Flickr

The last Optima conversion was as much fun as I’ve ever had in the shop. “An atheist, a communist and a Quaker walk into a bar. . . . . .

http://scooter-bangortoportland.blogspot.com/2015/05/1977-thermoform-optima-decked-canoe.html

I worked DougD like a rented mule during that 3-day marathon decked sailing canoe conversion.

The new one is a very nice 1975 Optima, 57lbs before tandem seat removal. Add in decent center seat, a modern rudder, foot controls and utility sail thwart, probably keep it close to 65lbs. My ’77 glass & nylon Optima, fully outfitted, came out at 57lbs, Doug’s ’77 woven roving version at 63lbs.

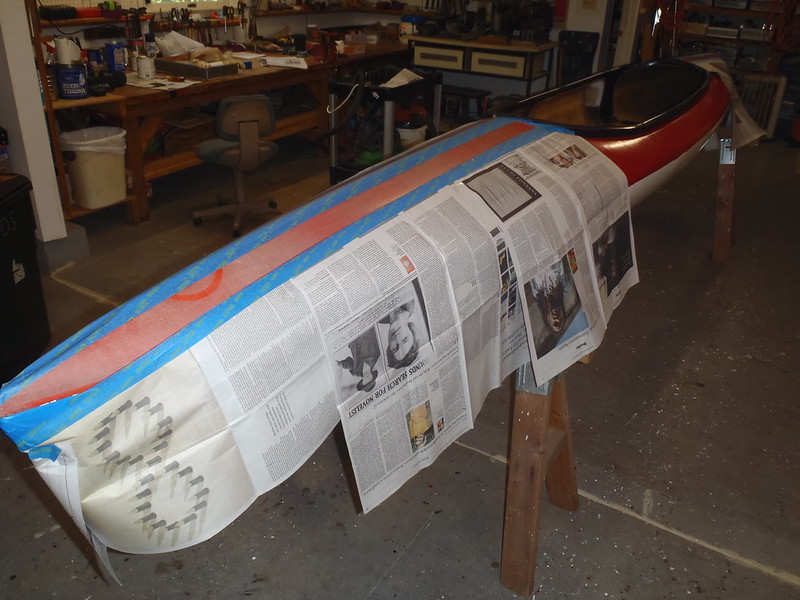

The bottom needs a coat (or two) of leftover EZ-Poxy white.

P9010008 by Mike McCrea, on Flickr

P9010008 by Mike McCrea, on Flickr

Not sure about the decks, they are in decent shape, but are un-sea kayak like smooth flush no-dimples or reveals. The decks could easily be rolled and tipped, and I have some leftover Fire Red EZ-poxy I need to use up.

P9010010 by Mike McCrea, on Flickr

P9010010 by Mike McCrea, on Flickr

The gel coated bottom is a better job than Doug’s or mine, seemingly a thinner gel layer, but better laid, three little missing chips, cumulatively the size of a pinky nail. The bottom scratches are numerous, but none are very deep. Good gel coat, reminiscent of early ‘70’s Mad River gel coat craftsmanship.

Another shop boat project at last; it’s not the rotted gunwales kevlar solo canoe of my dreams, but it’s something. Fill in the missing gel coat chips with G/flex, lightly sand the bottom, roll and tip some EZ-Poxy, then think about Fire Red decks.

P8300001 by Mike McCrea, on Flickr

P8300001 by Mike McCrea, on FlickrThe last Optima conversion was as much fun as I’ve ever had in the shop. “An atheist, a communist and a Quaker walk into a bar. . . . . .

http://scooter-bangortoportland.blogspot.com/2015/05/1977-thermoform-optima-decked-canoe.html

I worked DougD like a rented mule during that 3-day marathon decked sailing canoe conversion.

The new one is a very nice 1975 Optima, 57lbs before tandem seat removal. Add in decent center seat, a modern rudder, foot controls and utility sail thwart, probably keep it close to 65lbs. My ’77 glass & nylon Optima, fully outfitted, came out at 57lbs, Doug’s ’77 woven roving version at 63lbs.

The bottom needs a coat (or two) of leftover EZ-Poxy white.

P9010008 by Mike McCrea, on Flickr

P9010008 by Mike McCrea, on FlickrNot sure about the decks, they are in decent shape, but are un-sea kayak like smooth flush no-dimples or reveals. The decks could easily be rolled and tipped, and I have some leftover Fire Red EZ-poxy I need to use up.

P9010010 by Mike McCrea, on Flickr

P9010010 by Mike McCrea, on FlickrThe gel coated bottom is a better job than Doug’s or mine, seemingly a thinner gel layer, but better laid, three little missing chips, cumulatively the size of a pinky nail. The bottom scratches are numerous, but none are very deep. Good gel coat, reminiscent of early ‘70’s Mad River gel coat craftsmanship.

Another shop boat project at last; it’s not the rotted gunwales kevlar solo canoe of my dreams, but it’s something. Fill in the missing gel coat chips with G/flex, lightly sand the bottom, roll and tip some EZ-Poxy, then think about Fire Red decks.