A 1989 Old Town Discovery 169 has come into my life and I'm wondering if it is worth putting time and money into trying to prolong its existence.

The hull is significantly hogged between both seats and the yoke - this alone is probably not a huge issue for the mellow class I river use that might be in its' future, but the hogging seems to be exacerbating the cracking of the interior, as can be seen in the photos below.

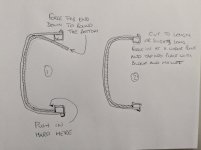

To fix the hogging, my impression is that options include some combo of shortening and re-attaching the yoke, and adding thwarts on either side of the yoke with some sort of vertical piece to push the floor of the boat out.

I think that without addressing the hogging, there is probably no point in trying to repair the cracks in the interior poly, as the flexing of the hull will continue to cause more cracking. Perhaps the cracks could be fixed with g/flex and fiberglass(and flame pre-treatment since it is poly)?

The outer hull is in remarkably good shape, with no signs of significant gashes - otherwise I wouldn't even be considering putting time into it. But maybe the best approach is to just gorilla tape the interior cracks to keep from soaking the foam core, and enjoy the boat on low-stakes water where when if it fails catastrophically it won't be a major disaster?

Any advice welcome, thanks!

The hull is significantly hogged between both seats and the yoke - this alone is probably not a huge issue for the mellow class I river use that might be in its' future, but the hogging seems to be exacerbating the cracking of the interior, as can be seen in the photos below.

To fix the hogging, my impression is that options include some combo of shortening and re-attaching the yoke, and adding thwarts on either side of the yoke with some sort of vertical piece to push the floor of the boat out.

I think that without addressing the hogging, there is probably no point in trying to repair the cracks in the interior poly, as the flexing of the hull will continue to cause more cracking. Perhaps the cracks could be fixed with g/flex and fiberglass(and flame pre-treatment since it is poly)?

The outer hull is in remarkably good shape, with no signs of significant gashes - otherwise I wouldn't even be considering putting time into it. But maybe the best approach is to just gorilla tape the interior cracks to keep from soaking the foam core, and enjoy the boat on low-stakes water where when if it fails catastrophically it won't be a major disaster?

Any advice welcome, thanks!