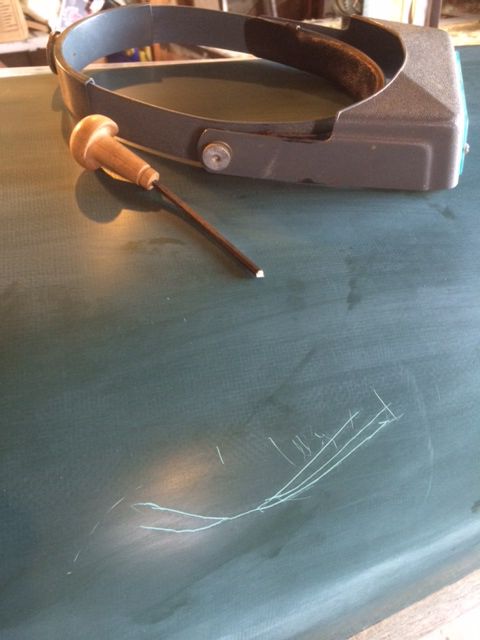

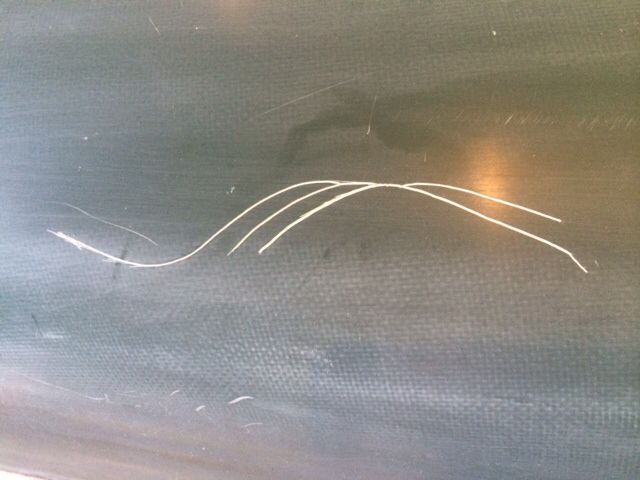

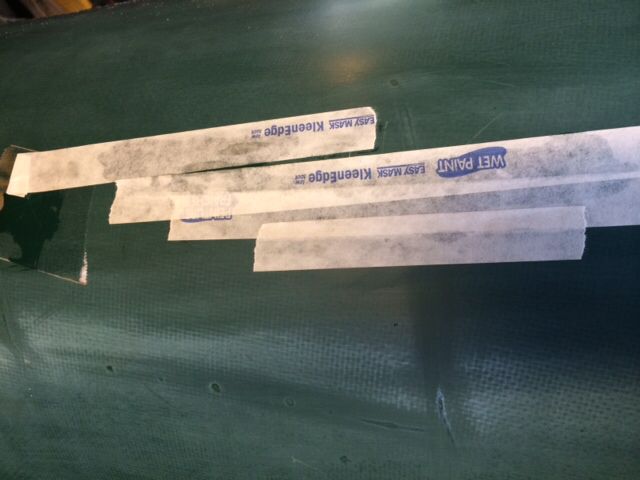

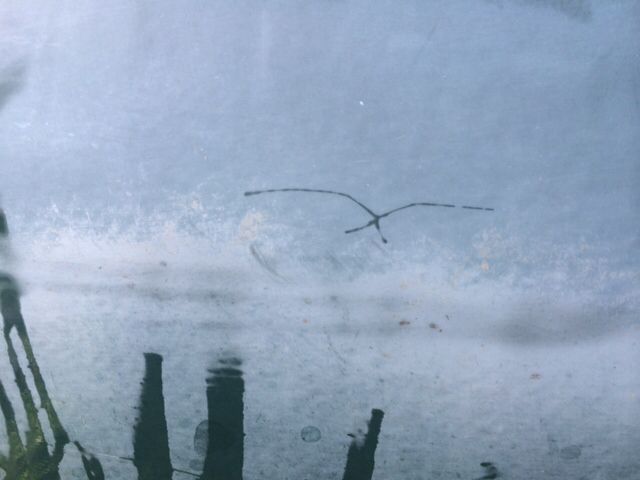

I've got a question for these esteemed members here. I'm a wood guy and when I'm faced with fiberglass work I pass it along to a buddy of mine. But this is different. I've got three Mad River Malecite canoes in the shop at the moment and I'm making a bunch of gunnels for all three boats. Two of the boats are paying customers and they are getting mahogany rails. The hulls are fine just needed a bit of compound and wax and they look great. The problem child is my boat. It was given to me about four years ago 'cause the owner didn't want to have me fix it, they just bought a new boat. The hull is badly sun damaged and didn't buff out so I decided to sand and paint it. It's a Kevlar hull and the gel coat has some fractures in it that I know will telegraph through the paint. So here is my question what is the best to seal up these fractures, or do have to sand through them. I don't think that is the best option. Would crazy glue run in the crack and fill it? I'll be painting it green again and will have cherry rails, decks and seats. Here are the photos.

Jim

Jim