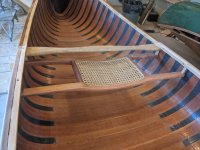

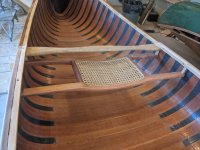

A couple of years ago I added a 3rd seat to my canoe. Worked great for tripping with 3 people especially if the 3rd was a kid. I've decided to pull it for now and if I do want 3 again I'm going to use a different seat so I need to plug 2 of the holes I made to hang it. Question is this - should I drill it out and plug it all the way through or not?