I skimmed through some past posts and I didn’t see what I was looking for. Its mostly about full repairs or scratches, and I’m not worried about scratches at this moment. It’s possible I overlooked a post or didn’t read thoroughly.

The hull of my canoe is flaking in sections and I’m not sure the correct way to go about this. It’s also possible that it’s my fault. When I bought the canoe, the outfitter did a quick job of applying new epoxy over the scratched hull. I asked for a boat that wasn’t repaired, but here we are, and it’s fine. I sanded down all of the raised chunks and sharp edges to what I thought was far enough but not too far. I did not go into any fibers while sanding.

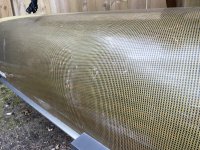

Here are some pictures of what I mean

So my question is.. what’s the best course of action for this? Sand it down and renew the epoxy?

Leave it be and paddle it?

Apply a coating over this as is?

The hull of my canoe is flaking in sections and I’m not sure the correct way to go about this. It’s also possible that it’s my fault. When I bought the canoe, the outfitter did a quick job of applying new epoxy over the scratched hull. I asked for a boat that wasn’t repaired, but here we are, and it’s fine. I sanded down all of the raised chunks and sharp edges to what I thought was far enough but not too far. I did not go into any fibers while sanding.

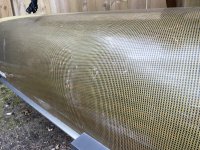

Here are some pictures of what I mean

So my question is.. what’s the best course of action for this? Sand it down and renew the epoxy?

Leave it be and paddle it?

Apply a coating over this as is?