A canoe seat can be the most important thing in a canoe !

It holds nearly all your weight. It needs to be comfortable, for both paddlers, in a tandem, as well as a solo.

It not ! The canoe will sit on the rack more often, than on the water !

I see a lot of beautifully built Cedar strip canoes, that have a factory flat cane seat.

That is OK ! But making that seat more comfortable, makes a world of difference.

Comfort by any means !

I'll be comparing Tandem seats. My first Aluminum canoe ( Lowe Line), had plastic molded seats. I still like those seats! For one, ?They kept both paddlers center in the hull. Nothing is worse than sitting in the stern seat, with the Bow paddler off to one side !

My first Cedar Strip canoe ( I still have it ), had solid flat seats . Yeah ! I never did paddle it much.

After a couple of trials, I came up with a contoured seat design. I still use the exact same pattern today. It allows me to use the same portage yoke on all my solo canoes. I can't imagine having 20 different yokes, for all my solos.

I chose Ash, as the wood for the frame, as it matched roughly, the Ash on my gunnels. It also has the strength to support a heavy paddler ! I very good friend made a beautiful Cherry seat. Laced it with Para cord. It broke on him in the BWCA , and he had to paddle sitting on a bag stuffed under his seat.

Now for lacing. I had seen so many cane seats, in poor shape, while the rest of the canoe was decent. Don't get me wrong ! I love the look of cane ! Just not the durability. That is where the Snow Shoe cord came into the picture. I bought enough cord, for a couple of canoes, then I purchased a 300 yd roll from.

snowshoe.com

snowshoe.com

My roll is running low now, but when it's gone ? I'll go to Nylon Webbing.

In Truth ? I'd recommend the Nylon webbing for its durability and comfort. It can be found in a lot of different colors also.

OK, back to the seat frame. Flat versus contoured already discussed.

What dimensions? I want a seat that allows me to shift side to side, and fore and aft, to correct trim, and still be comfortable. Comfort by all means !.

Most factory seats don't allow this ! They are not deep enough to allow the paddler to shift his weight fore and aft.

I will give you the dimensions, I use, but use them as a guide line, to meet your needs. They are by no means set in stone !

The other thing I note on Home made, as well as Factory seats ? They do not use a Mortise to fit the rails and braces together. Simple Mortise makes a solid frame without a dowel. or screw, that can give way.

The last thing I'll touch on ? How high should the seats be from the keel ? Everyone has different requirements, but for me ? 9 to 10" , measured from the top of the contour, to the keel, is about right on a solo. Often times a little lower on a tandem , for stability. Again Comfort, Comfort, Comfort.

Now for the pics.

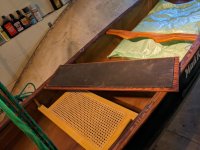

The template

The simple mortise that holds the frame together

The frames are 11" deep. You can easily go deeper.

16" wide. Again make them to suit you. 16" works for me 18" might be better. Note there is a 1" dropin 16"

I lace the seats quite loose. The Spar Varnish shrinks the cord. By the way. the cord is 1/2" wide. Holes are 3/16", 7/8" apart.

Finished seat.

The front edge is about 3" down from the top of the shear, with the valley of the contour 1" deeper.

I am able to sit to one side, if I need to heel the hull. I don't usually need to.

Jim

It holds nearly all your weight. It needs to be comfortable, for both paddlers, in a tandem, as well as a solo.

It not ! The canoe will sit on the rack more often, than on the water !

I see a lot of beautifully built Cedar strip canoes, that have a factory flat cane seat.

That is OK ! But making that seat more comfortable, makes a world of difference.

Comfort by any means !

I'll be comparing Tandem seats. My first Aluminum canoe ( Lowe Line), had plastic molded seats. I still like those seats! For one, ?They kept both paddlers center in the hull. Nothing is worse than sitting in the stern seat, with the Bow paddler off to one side !

My first Cedar Strip canoe ( I still have it ), had solid flat seats . Yeah ! I never did paddle it much.

After a couple of trials, I came up with a contoured seat design. I still use the exact same pattern today. It allows me to use the same portage yoke on all my solo canoes. I can't imagine having 20 different yokes, for all my solos.

I chose Ash, as the wood for the frame, as it matched roughly, the Ash on my gunnels. It also has the strength to support a heavy paddler ! I very good friend made a beautiful Cherry seat. Laced it with Para cord. It broke on him in the BWCA , and he had to paddle sitting on a bag stuffed under his seat.

Now for lacing. I had seen so many cane seats, in poor shape, while the rest of the canoe was decent. Don't get me wrong ! I love the look of cane ! Just not the durability. That is where the Snow Shoe cord came into the picture. I bought enough cord, for a couple of canoes, then I purchased a 300 yd roll from.

Snowshoe.com - Traditional Snowshoes, Snowshoe Kits, Winter Camping

Traditional snowshoes, snowshoe furniture kits, repair and lacing products, toboggan kits, and more. No Trail Too Deep.

My roll is running low now, but when it's gone ? I'll go to Nylon Webbing.

In Truth ? I'd recommend the Nylon webbing for its durability and comfort. It can be found in a lot of different colors also.

OK, back to the seat frame. Flat versus contoured already discussed.

What dimensions? I want a seat that allows me to shift side to side, and fore and aft, to correct trim, and still be comfortable. Comfort by all means !.

Most factory seats don't allow this ! They are not deep enough to allow the paddler to shift his weight fore and aft.

I will give you the dimensions, I use, but use them as a guide line, to meet your needs. They are by no means set in stone !

The other thing I note on Home made, as well as Factory seats ? They do not use a Mortise to fit the rails and braces together. Simple Mortise makes a solid frame without a dowel. or screw, that can give way.

The last thing I'll touch on ? How high should the seats be from the keel ? Everyone has different requirements, but for me ? 9 to 10" , measured from the top of the contour, to the keel, is about right on a solo. Often times a little lower on a tandem , for stability. Again Comfort, Comfort, Comfort.

Now for the pics.

The template

The simple mortise that holds the frame together

The frames are 11" deep. You can easily go deeper.

16" wide. Again make them to suit you. 16" works for me 18" might be better. Note there is a 1" dropin 16"

I lace the seats quite loose. The Spar Varnish shrinks the cord. By the way. the cord is 1/2" wide. Holes are 3/16", 7/8" apart.

Finished seat.

The front edge is about 3" down from the top of the shear, with the valley of the contour 1" deeper.

I am able to sit to one side, if I need to heel the hull. I don't usually need to.

Jim

Last edited: