- Joined

- Jul 6, 2021

- Messages

- 643

- Reaction score

- 1,180

I have enough boats in the shop right now, two still in progress and another arriving next month. Plenty of fall/winter projects. And there I was whining that I needed a boat to work on; best finish up the two I started months ago.

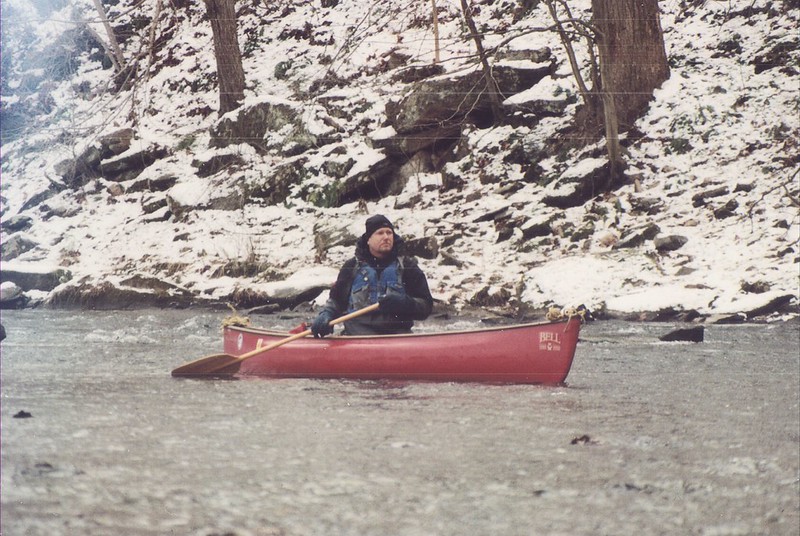

I’m in no rush to work on the Yellowstone Solo, but wanted to get semi-started while it was still scrub-a-dub hose and brush weather. I opted to bring it home sooner rather than later for another reason as well; there were just enough pieces of inwale left to transport the canoe inverted on roof racks without wobbling like a bowl of jelly or damaging the naked Royalex.

PA310005 by Mike McCrea, on Flickr

PA310005 by Mike McCrea, on Flickr

The remaining gunwale pieces and screws were all still there when I got home, didn’t lose any tire flatteners on the highway, and I’ll save those screws of course. Not that I’ll ever do wood gunwales again.

But, even before removing the screws, I needed to wash it. I can’t stand having a dirty boat in a crowded shop, I know I’ll be leaning over it or brushing against it, and then contaminating whatever paint, varnish, epoxy, etc I’m working on. So the YS got (sharps carefully) scrub brushed with the screws still sticking out.

PB010008 by Mike McCrea, on Flickr

PB010008 by Mike McCrea, on Flickr

I wasn’t leaning over, screws poking belly, to wash the inside. Later for that, after the YS is upright in the shop and the few remaining pieces of inwale and screws have been removed.

Last permit is from 2007 and has a 2001 HIN. It was a solo canoe review boat, so probably the first year for the RX Yellowstone Solo. One oddity, common on fresh-from-the-factory roof racked Royalex hulls, it sports a series of small dimples in the Royalex. Right where the belly line rope hitches pressed against the still soft RX foam core when tied to the roof racks. Our fresh from the factory RX Wilderness sports a series of those hitch dimples as well.

Really fresh RX (maybe T-formex?) might be better rack secured for the first year or so using cam straps. I hate cam straps.

Washed, up close and personal and OH NO! The stems are worn. Whatever shall I do? If only there was some lightweight, un-gurgling flush fitted, incredibly abrasion resistant material I could install. I’ll have to ask around for suggestions. Maybe Glenn knows.

PB010009 by Mike McCrea, on Flickr

PB010009 by Mike McCrea, on Flickr

With the outside cleaned and the YS back in the (getting boat crowded) shop this is what was left of the still attached wood gunwales. Eh, that’ll buff right out.

PB010014 by Mike McCrea, on Flickr

PB010014 by Mike McCrea, on Flickr

The seat was half dangling free when I pick it up, and I pulled it out before racking the canoe for the drive home, so it didn’t become highway debris. The seat may be salvageable, the truss drops are rot decayed gonners.

PB010013 by Mike McCrea, on Flickr

PB010013 by Mike McCrea, on Flickr

The YS is a good kneeling canoe, especially with a skilled paddler. That’s two strikes against me. I may need to have a talk with Conk when I get to the seat stage, but I have a long ways to go before then.

I’m in no rush to work on the Yellowstone Solo, but wanted to get semi-started while it was still scrub-a-dub hose and brush weather. I opted to bring it home sooner rather than later for another reason as well; there were just enough pieces of inwale left to transport the canoe inverted on roof racks without wobbling like a bowl of jelly or damaging the naked Royalex.

PA310005 by Mike McCrea, on Flickr

PA310005 by Mike McCrea, on FlickrThe remaining gunwale pieces and screws were all still there when I got home, didn’t lose any tire flatteners on the highway, and I’ll save those screws of course. Not that I’ll ever do wood gunwales again.

But, even before removing the screws, I needed to wash it. I can’t stand having a dirty boat in a crowded shop, I know I’ll be leaning over it or brushing against it, and then contaminating whatever paint, varnish, epoxy, etc I’m working on. So the YS got (sharps carefully) scrub brushed with the screws still sticking out.

PB010008 by Mike McCrea, on Flickr

PB010008 by Mike McCrea, on FlickrI wasn’t leaning over, screws poking belly, to wash the inside. Later for that, after the YS is upright in the shop and the few remaining pieces of inwale and screws have been removed.

Last permit is from 2007 and has a 2001 HIN. It was a solo canoe review boat, so probably the first year for the RX Yellowstone Solo. One oddity, common on fresh-from-the-factory roof racked Royalex hulls, it sports a series of small dimples in the Royalex. Right where the belly line rope hitches pressed against the still soft RX foam core when tied to the roof racks. Our fresh from the factory RX Wilderness sports a series of those hitch dimples as well.

Really fresh RX (maybe T-formex?) might be better rack secured for the first year or so using cam straps. I hate cam straps.

Washed, up close and personal and OH NO! The stems are worn. Whatever shall I do? If only there was some lightweight, un-gurgling flush fitted, incredibly abrasion resistant material I could install. I’ll have to ask around for suggestions. Maybe Glenn knows.

PB010009 by Mike McCrea, on Flickr

PB010009 by Mike McCrea, on FlickrWith the outside cleaned and the YS back in the (getting boat crowded) shop this is what was left of the still attached wood gunwales. Eh, that’ll buff right out.

PB010014 by Mike McCrea, on Flickr

PB010014 by Mike McCrea, on FlickrThe seat was half dangling free when I pick it up, and I pulled it out before racking the canoe for the drive home, so it didn’t become highway debris. The seat may be salvageable, the truss drops are rot decayed gonners.

PB010013 by Mike McCrea, on Flickr

PB010013 by Mike McCrea, on FlickrThe YS is a good kneeling canoe, especially with a skilled paddler. That’s two strikes against me. I may need to have a talk with Conk when I get to the seat stage, but I have a long ways to go before then.