-

Happy Birthday, Charles Lindbergh (1902-74)! 🛩️🗽🗼

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

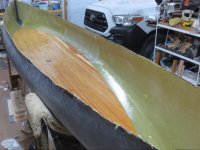

basalt Innegra tandem tripper.

- Thread starter Mp214parks

- Start date

Not to throw a wrench in here but the Northwind description of their new canoe says that the basalt inegra is stiff enough to not need ribs or a foam insert. Wonder is vaccum bagging makes a big difference or if they have their own special inegra.

Does the weight equal that of the foam cored boat? I might be wrong but I'd guess the weight is a good bit higher due to more layers of cloth.

Alan

Well carbon Innegra is certainly less rigid than plain carbon. And Basalt Innegra is certainly less rigid than plain basalt. Basalt is very similar to S glass. The prospector my buddy just finished is 5 layers of 7 oz basalt Innegra with a lot of foam in there. You can really tell where there no foam. It wouldn’t be stiff enough without it.

That would look sweet. If I did that, I would probably also do cedar gunwales wrapped in glass sleeve. Originally I wantted to have “no wood and no metal”. Just for bragging rights. I’ve got time to change my mind. You guys are good at making that happen. My wife dragged me to Hawaii with the kids. So all I can do now is wait. Definitely a first world problem.

Last edited:

Yes, I did seal one end and was very happy with the clean result and saved effort later. Also I did just an S-glass football on top of the full layer of E-glass for abrasion resistance (and less cost). Have fun in Hawaii! Plenty of time to ponder all this another day!

I just got off the phone with an old buddy who is trying to convince me to build a female mold for this project. Anyone care to sway me one way or the other? He is saying if I use the male plug, I’ll be sanding my canoe for a week.

Females molds work great for hand lay ups but you need to make a male plug to make a female mold so that's a lot of work and cost for one canoe

I just got off the phone with an old buddy who is trying to convince me to build a female mold for this project. Anyone care to sway me one way or the other? He is saying if I use the male plug, I’ll be sanding my canoe for a week.

I sand my Strippers, it's no different than sanding a hull off a male mold !

A week ? I'd guess, scraping and sanding could be easily done in a day.

If you're planning on producing several hulls (10 or more) By all means, build a Female mold ! 2 or 3 ? A Male mold without question, in my book anyway !

Maybe your buddy wants You to build a hull for him ?

Jim

Unless you’re going into production, a female mold would be too much work IMHO

and with that tumblehome you would likely need to split the mold along the keel line

working off a male plug with the stems left open would be pretty efficient

maybe even do your glass layers on the plug pop it free then add your basalt from the inside

the wet out would be more reliable that way

and with that tumblehome you would likely need to split the mold along the keel line

working off a male plug with the stems left open would be pretty efficient

maybe even do your glass layers on the plug pop it free then add your basalt from the inside

the wet out would be more reliable that way

I can't see the female mold being an overall time savings, as you'd spend so much time making the mold as to negate any saved sanding of the final boat. That being said, if you were interested in making more than 1 hull...I could always use a tandem tripper myself!

That's also a better pic of your hull ! Not near as much Tumblehome, as my hulls.

It's definitely a flat water racing hull. Plumb stems, little or no rocker, or flare.

Do you have glass or epoxy on the outwhale clamped to the mold ?

I'm guessing the Carbon wrapped foam, is just an outwhale ? Not both inwhale and outwhale ?

In my earlier composite builds, I stressed about getting a wrinkle free plastic release. Of course, I didn't. After I was done with three or four layers of cloth, The wrnkles were not visible from the Outside.

Once I pulled the hull, I had little ridges of cured epoxy, in the inside of the hull. They were easily dealt with using a curved scraper !

Making Progress ! Good !

Jim

It's definitely a flat water racing hull. Plumb stems, little or no rocker, or flare.

Do you have glass or epoxy on the outwhale clamped to the mold ?

I'm guessing the Carbon wrapped foam, is just an outwhale ? Not both inwhale and outwhale ?

In my earlier composite builds, I stressed about getting a wrinkle free plastic release. Of course, I didn't. After I was done with three or four layers of cloth, The wrnkles were not visible from the Outside.

Once I pulled the hull, I had little ridges of cured epoxy, in the inside of the hull. They were easily dealt with using a curved scraper !

Making Progress ! Good !

Jim

Yep carbon over Foam. Just the outwales for now. It’s just got packaging tape on the hull and the spruce slats. Hopefully that releases. Still waiting on some fabric for the lay up. I’ll do the inwales when I trim.

What’s the cross sectional shape of your outwhale? You’ll need a flat on one side to mate with the hull. Depending on your sleeving, it might not want to conform to your cross section.

is it the plan to wet out the carbon sleeving then clamp the outwhale in place?

It’s always been a bit of a challenge for me to keep carbon sleeving in intimate contact with my foam thwarts.

I had dreamt of pefabbed gunnels in a full round cross section. I was stalled by how to make a straight slot through the length of the cured gunnel.

anyway I’m anxious to see how your outwhale turn out

is it the plan to wet out the carbon sleeving then clamp the outwhale in place?

It’s always been a bit of a challenge for me to keep carbon sleeving in intimate contact with my foam thwarts.

I had dreamt of pefabbed gunnels in a full round cross section. I was stalled by how to make a straight slot through the length of the cured gunnel.

anyway I’m anxious to see how your outwhale turn out

It’s a square with the bottom angled at 25 degrees. I can’t remember why that shape is called. And I hand sanded with 60 grit too. I had the same problem on my test section. I think one trick is to get a large enough foam into the sleeve size you are using. Also after I wet it out I massaged the cloth to lengthen as much as possible. This got me a couple more inches (and a mess). Now it’s clamped on the the two sides, so the only possible place of problem would be the top and bottom. Right now it looks tight. Also I pinched the ends and taped them so they wouldn’t creep back on me.

I just pulled the first outwhale off the mold. It appears to have a solid lamination to the foam everywhere. I think it will get a final wrapping in S glass when the boat is done. But right now it weighs 8 1/2 oz.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 81

- Views

- 12K