- Joined

- Jul 6, 2021

- Messages

- 643

- Reaction score

- 1,180

I needed to hand sand the edges and inside the rod holes on fishing thwart, and create a short bottom “shelf” to hold the ends of the angled rods outboard for paddle trolling. Turning again to the scrap thwart pile I found a likely under-shelf candidate, cut it length and spade bit drilled the holes at a matching rod angles. No sense in wasting a piece of now too short already finished wood, I cut the short shelf drops from that same rectangular thwart piece.

Fishing thwart pieces clamped in rough position on the bench, tested and approved, then taken apart for butt end sealing.

PC270017 by Mike McCrea, on Flickr

PC270017 by Mike McCrea, on Flickr

With those remaining brightwork pieces cut and sanded I turned to some minor epoxy work. First some G/flex paint over and seeped into the various sanded and cleaned interior cracks. To make certain that I didn’t miss any, after sanding and cleaning I marked those cracks with a Sharpie.

PC270018 by Mike McCrea, on Flickr

PC270018 by Mike McCrea, on Flickr

Yowza, that is a lot of teeny vinyl skin cracks. Whatever poorly install and failed adhesive was used for the thigh strap pads did no favors to the vinyl, but those cracks are only skin deep. The crack over the stern skid plate was a bit more of a crevice, I filled it first and went back to refill it again after the G/flex had seeped in.

PC280021 by Mike McCrea, on Flickr

PC280021 by Mike McCrea, on Flickr

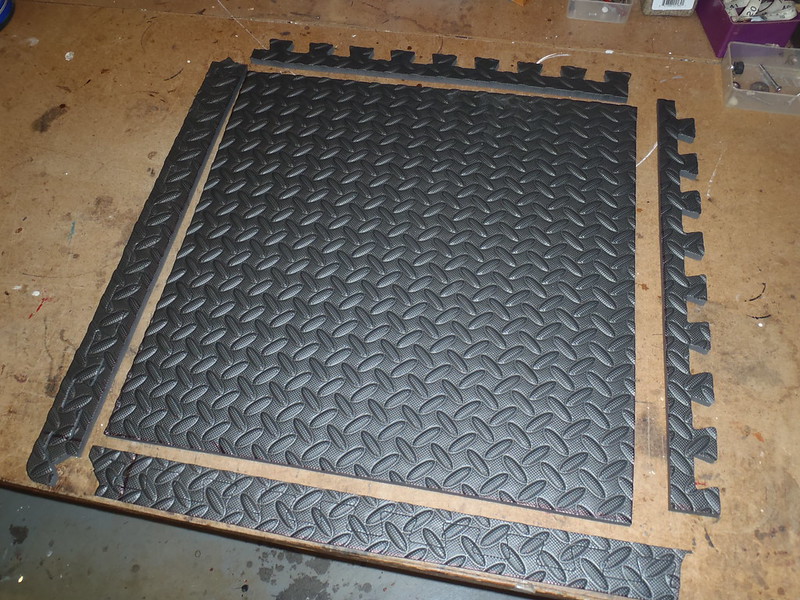

With an unknown seepage factor I was not stingy with the G/flex. Once the epoxy hardens I can sand any epoxy puddles more flush. I epoxy sealed even the most minor of surface cracks under the thigh brace pads; in part hoping that will stop any water/dirt/grit infiltration promoting future spread, but also because I plan to install some exercise flooring using contact cement, and I really don’t want to chance that adhesive creeping into any cracks and dissolving the ABS substrate.

With the Explorer planned to be left upside down near ground level eight months a year I wanted some serious sealant on the prone to bacterial rot butt ends, on every brightwork piece. So, before the spar urethane coats, some epoxy resin on the sanded and newly thirsty age-dried butt ends, especially the inwale edge of the truss hangers, which had evidenced some incipient bacterial blackening, but also on the rail ends of the seats, yoke and utility thwart. All the butt ends; I do not like boats stored on or near the ground, but have no choice at the reservoir launch.

I had a small amount of G/flex left in the pot from the crack repairs, and a single pump of West 105/206 added to the leftovers made just enough to paint epoxy on all of the butt ends, plus an inch inward on the surface, where the brightwork is held moisture & dirt trapping below the inwales, or seated against other wood pieces. The truss drops got epoxy sealed too, tops and bottoms.

PC280022 by Mike McCrea, on Flickr

PC280022 by Mike McCrea, on Flickr

PC280025 by Mike McCrea, on Flickr

PC280025 by Mike McCrea, on Flickr

The brightwork can hang epoxy curing for a spell while I attend to the last, and largest, epoxy task.

Fishing thwart pieces clamped in rough position on the bench, tested and approved, then taken apart for butt end sealing.

PC270017 by Mike McCrea, on Flickr

PC270017 by Mike McCrea, on FlickrWith those remaining brightwork pieces cut and sanded I turned to some minor epoxy work. First some G/flex paint over and seeped into the various sanded and cleaned interior cracks. To make certain that I didn’t miss any, after sanding and cleaning I marked those cracks with a Sharpie.

PC270018 by Mike McCrea, on Flickr

PC270018 by Mike McCrea, on FlickrYowza, that is a lot of teeny vinyl skin cracks. Whatever poorly install and failed adhesive was used for the thigh strap pads did no favors to the vinyl, but those cracks are only skin deep. The crack over the stern skid plate was a bit more of a crevice, I filled it first and went back to refill it again after the G/flex had seeped in.

PC280021 by Mike McCrea, on Flickr

PC280021 by Mike McCrea, on FlickrWith an unknown seepage factor I was not stingy with the G/flex. Once the epoxy hardens I can sand any epoxy puddles more flush. I epoxy sealed even the most minor of surface cracks under the thigh brace pads; in part hoping that will stop any water/dirt/grit infiltration promoting future spread, but also because I plan to install some exercise flooring using contact cement, and I really don’t want to chance that adhesive creeping into any cracks and dissolving the ABS substrate.

With the Explorer planned to be left upside down near ground level eight months a year I wanted some serious sealant on the prone to bacterial rot butt ends, on every brightwork piece. So, before the spar urethane coats, some epoxy resin on the sanded and newly thirsty age-dried butt ends, especially the inwale edge of the truss hangers, which had evidenced some incipient bacterial blackening, but also on the rail ends of the seats, yoke and utility thwart. All the butt ends; I do not like boats stored on or near the ground, but have no choice at the reservoir launch.

I had a small amount of G/flex left in the pot from the crack repairs, and a single pump of West 105/206 added to the leftovers made just enough to paint epoxy on all of the butt ends, plus an inch inward on the surface, where the brightwork is held moisture & dirt trapping below the inwales, or seated against other wood pieces. The truss drops got epoxy sealed too, tops and bottoms.

PC280022 by Mike McCrea, on Flickr

PC280022 by Mike McCrea, on Flickr PC280025 by Mike McCrea, on Flickr

PC280025 by Mike McCrea, on FlickrThe brightwork can hang epoxy curing for a spell while I attend to the last, and largest, epoxy task.