Maybe it’s better folks go to the WCHA for information on working on wood canoes.

-

Happy Ferris Wheel and Valentine's Day! 🎡💝😍

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Chestnut(?)

- Thread starter Robin

- Start date

Robin, I didn't mean to ask you to do something you otherwise weren't going to do in this thread. My view is that you are a very experienced and influential non-professional in working on wood canoes, that many of the same people read and post on this site as the WCHA forums, and that both sites have valuable information on the building, restoration and repair of wood canoes. Currently, this site has platform software (completely up-to-date Xenforo) for posting pictures and videos on a variety of devices that is superior to any other canoe site of which I'm aware. I'm proud of that, and obviously want to encourage as many picture-rich build, restoration, repair and outfitting threads on this site as possible.

Relatedly, as a director of the WCHA, I will strongly support, advocate and vote for technical and financial enhancements to the WCHA forums and website if that's a direction the organization wants to go.

Relatedly, as a director of the WCHA, I will strongly support, advocate and vote for technical and financial enhancements to the WCHA forums and website if that's a direction the organization wants to go.

I'm on both forums, and find them useful.

About lumberyard spruce, my dad made a paddle of it years ago, I still use it. I built a mast for a dory from it, served well. I think we should use the best material we can find and afford, in keeping with the quality of the boat.

About lumberyard spruce, my dad made a paddle of it years ago, I still use it. I built a mast for a dory from it, served well. I think we should use the best material we can find and afford, in keeping with the quality of the boat.

My pond finally cleared of ice so I was able to soak the spruce inwales for a couple of days. I made two jigs for bending and then I steamed them with the bag method.

Robin, some questions so I can understand the bending processes better.

Do you only have to steam the ends of inwales, not the full length, as your bag method pictures seem to show?

Would you ever have to bend the inwales (or outwales) in two directions for a canoe with high, recurved stems—that is, bending both inward and upward?

Can one gunwale bending jig be used for all or most canoes, or would a builder/restorer have to have several bending jigs for different shaped sheerlines?

Do you need a jig to bend steamed ribs, or do you just steam ribs and bend them by hand onto the canoe form for a new build or into the canoe for a restoration?

Robin, some questions so I can understand the bending processes better.

Yes, just steam the ends that are getting bentDo you only have to steam the ends of inwales, not the full length, as your bag method pictures seem to show?

I don't think so, I would think you could bend them inwards without much effort. It is possible to set up a jig to bend them in two directions, I just don't remember ever seeing a canoe that would need it.Would you ever have to bend the inwales (or outwales) in two directions for a canoe with high, recurved stems—that is, bending both inward and upward?

I would say if you were a professional you would probably have one for each of the popular canoes, and then when you had a rare canoe come in you would build/save the new jig for it just in case. Schuyler Thomson had a few that I saw labeled for different canoes. This canoe I'm working on had the ends repaired without using a jig so my pattern for the jig is probably not historically correct, but close.Can one gunwale bending jig be used for all or most canoes, or would a builder/restorer have to have several bending jigs for different shaped sheerlines?

No, not for the ribs, but I have seen a jig for "cant ribs", which are two thin and wide ribs at each end of the canoe, one on either side. I don't use a jig for them, but some do.Do you need a jig to bend steamed ribs, or do you just steam ribs and bend them by hand onto the canoe form for a new build or into the canoe for a restoration?

On a restoration, you bend the new rib on the outside of the canoe, over the next wider rib. If you have 6 broken ribs, like this canoe, it's best to remove and replace only 2 at a time, leaving an old rib to help keep the form of the canoe if possible.

Thanks, Robin. I've gotten more interested in build and restoration techniques now that I'm more involved with w/c canoes and the WCHA.

- Joined

- Apr 20, 2022

- Messages

- 262

- Reaction score

- 527

Appreciate the questions and the responses Glen and Robin. Very interestingThanks, Robin. I've gotten more interested in build and restoration techniques now that I'm more involved with w/c canoes and the WCHA.

- Joined

- Apr 20, 2022

- Messages

- 262

- Reaction score

- 527

Thank you for the responses… very helpfulYes, just steam the ends that are getting bent

I don't think so, I would think you could bend them inwards without much effort. It is possible to set up a jig to bend them in two directions, I just don't remember ever seeing a canoe that would need it.

I would say if you were a professional you would probably have one for each of the popular canoes, and then when you had a rare canoe come in you would build/save the new jig for it just in case. Schuyler Thomson had a few that I saw labeled for different canoes. This canoe I'm working on had the ends repaired without using a jig so my pattern for the jig is probably not historically correct, but close.

No, not for the ribs, but I have seen a jig for "cant ribs", which are two thin and wide ribs at each end of the canoe, one on either side. I don't use a jig for them, but some do.

On a restoration, you bend the new rib on the outside of the canoe, over the next wider rib. If you have 6 broken ribs, like this canoe, it's best to remove and replace only 2 at a time, leaving an old rib to help keep the form of the canoe if possible.

I was more nervous responding correctly to Glenn's post than bending those inwales, haha,

BTW, in my last picture, you can really see the tumblehome in the canoe, a pretty sure sign that the canoe was built on a pre fire Chestnut form. (circa 1922 or before)

BTW, in my last picture, you can really see the tumblehome in the canoe, a pretty sure sign that the canoe was built on a pre fire Chestnut form. (circa 1922 or before)

Robin, your mention of tumblehome made me go out to the barn to look at my current Chestnut project. Does the tumblehome in this hull appear similar to yours? The previous owner claimed this canoe is a pre-fire Chestnut Bobs Special, but the depth of the hull (13.5") more closely resembles a Chestnut Ranger than a Bobs (12").

Also, I started thinking about hull measurements in general. I think over time Chestnut canoe identification based only on measurements becomes difficult due to a lack of apparent factory quality control as the company neared closing.

Here's how I measure extreme beam (below the gunwale). I clamp two framing squares together with the tongues just touching the widest part of the hull, then measure the distance between them. In this case, the widest beam is 36 7/16", while the gunwale (plank to plank) width is 35".

Certainly not highly important information here.... just fooling around with projects while it's too cold to paddle!

Also, I started thinking about hull measurements in general. I think over time Chestnut canoe identification based only on measurements becomes difficult due to a lack of apparent factory quality control as the company neared closing.

Here's how I measure extreme beam (below the gunwale). I clamp two framing squares together with the tongues just touching the widest part of the hull, then measure the distance between them. In this case, the widest beam is 36 7/16", while the gunwale (plank to plank) width is 35".

Certainly not highly important information here.... just fooling around with projects while it's too cold to paddle!

Yes, that's the same tumblehome I have. I would say it's a pre fire. I have 5 other Chestnuts and non of them have any tumblehome. As far as measurements, I gave up trying to figure them out. My Pal is 13" from top of ribs to under the center thwart, or 15" from the plank to the top of the inhales.?

Patrick,The previous owner claimed this canoe is a pre-fire Chestnut Bobs Special, but the depth of the hull (13.5") more closely resembles a Chestnut Ranger than a Bobs (12").

Was this the canoe that had the heart shape deck with faded outline of a Chestnut decal on it?

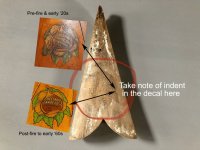

If so, here's a little graphic I put together using known samples of a confirmed pre-fire decal (1918) at the Canadian Canoe Museum and the version that appears from the post-fire period to early 60s (this one on a 50's era pleasure class). You'll see a well defined "indent" on the right side that was part of the leafy design in the post-fire period but not found in the pre-fire decal.

Yes, Murat, that deck is from the canoe I mentioned just above. Thanks for your graphic. It's probably the most definitive clue I've seen that helps to date my canoe! I have no reason to doubt that the decks on the canoe in question are not original, so I'm going with post-fire.

The nature of the canoe construction is most interesting to me. It's so lightly built that the first assumption is to call it a Bobs, but the depth doesn't square with the catalog dimensions for a Bobs; dimensionally it's more like a Prospector 15' Ranger, but certainly built much lighter. Maybe a one-off for a discerning customer.... I'm really looking forward to finishing her. I'll bet it will be a true lightweight weighing in the 50# range. The 1950 catalog had a category called the Chestnut 50-lb. Special: first grade finish telegram code was Bobs, second grade code Bantam.

From the 1921 catalog: Chestnut measurements seem to be suspect. Perhaps this is from where some of the confusion originates.

The nature of the canoe construction is most interesting to me. It's so lightly built that the first assumption is to call it a Bobs, but the depth doesn't square with the catalog dimensions for a Bobs; dimensionally it's more like a Prospector 15' Ranger, but certainly built much lighter. Maybe a one-off for a discerning customer.... I'm really looking forward to finishing her. I'll bet it will be a true lightweight weighing in the 50# range. The 1950 catalog had a category called the Chestnut 50-lb. Special: first grade finish telegram code was Bobs, second grade code Bantam.

From the 1921 catalog: Chestnut measurements seem to be suspect. Perhaps this is from where some of the confusion originates.

- Joined

- Apr 20, 2022

- Messages

- 262

- Reaction score

- 527

Looks great! The lines are beautiful!Installed the new inwales, which always looks good and motivates me, now for those 6 new ribs.View attachment 135106

Very nice work Robin!Installed the new inwales, which always looks good and motivates me, now for those 6 new ribs.View attachment 135106

Never occurred to me you'd steam bend them onto the outside hull. I saw birch bark canoe ribs soaked in hot water and bent to tight friction fit into the interior, and so assumed all ribs were fit into the interior likewise. I'm following this (and other) wc projects here on CT. Thanks.

Never occurred to me you'd steam bend them onto the outside hull. I saw birch bark canoe ribs soaked in hot water and bent to tight friction fit into the interior, and so assumed all ribs were fit into the interior likewise. I'm following this (and other) wc projects here on CT. Thanks.

Yes, every rib is bent over the next biggest rib to where it should be installed. Makes for a tight fit. I have only removed two of the 6 ribs to be replaced, and there is still a rib between where they came out. That helps to preserve the shape of the canoe, no bulges. After installing the first two ribs, I’ll remove two more ribs, install new, then repeat.

Similar threads

- Replies

- 3

- Views

- 1K