G

Guest

Guest

If I am reading Mad River’s list of models/materials correctly 1984 was the first year for the “Explorer 16 RX”.

A Vermont-era RX canoe, with some seriously substantial Royalex. It has a memorable used-boat history; someone was looking for a bit of a do-everything used canoe. The RX Explorer came up for short money ($200) and I hurried to send them to the seller.

The potential buyer took a look and passed because one cane seat was busted out. OK then dummy, in that case it’s all mine. Other than the busted cane the canoe was in excellent condition. I no-dicker handing the guy four $50’s, and while I was racking it he started bringing out other throw-in freebies.

Two Voyageur paddles, two Clement paddles, a boat cart, a tee-bar for a receiver hitch, a side-motor mount, some decent PFD’s. I had started to tie on and drive away like I stole it, but changed my mind and took my time as he kept bringing freebies out.

Originally rebuilt as a center seat solo with kneeling thwart poling boat (with a hidden sail mount) for my older son’s proclivities it was soon displaced by lighter hulls. MRC speced it in Royalex at 72 lbs in the 1994 catalog, which was in later/lighter/less robust RX, and even center seat soloized it seemed every bit of that and then some.

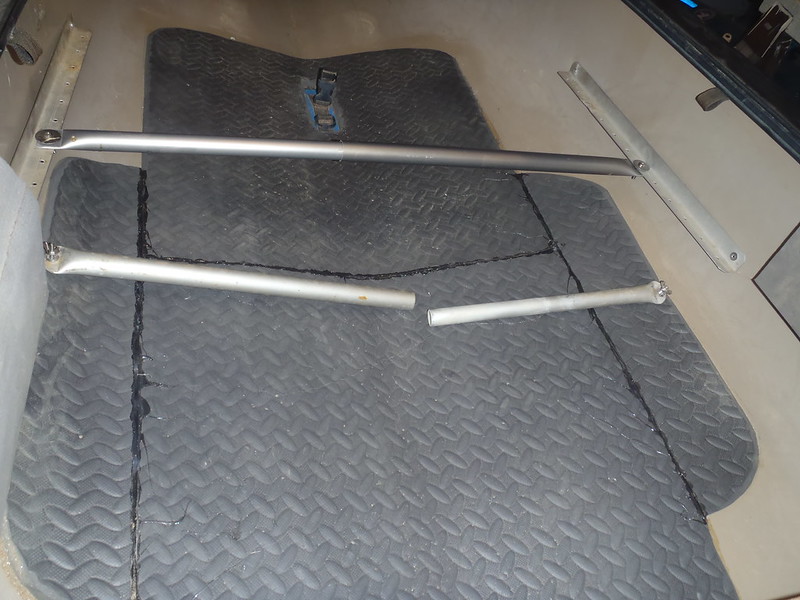

I brought it into the shop a couple of years ago and began stripping it down, losing the padded kneeling thwart and adding some exercise flooring to cover old minicel padding smutch residue left on the floor from two or three past outfittings.

Mid-way through that re-re-built a poling friend stopped by, and I sent him home with the (unfinished) RX Explorer. His then-current poling boat was a 3-seater, yoke and thwarted glass/kev Explorer I rebuilt years ago, and there was no room between seats and thwarts to move around. The yet unfinished RX Explorer had almost 5 feet of walk around room between the solo seat and front thwart with the kneeling thwart removed.

P2100003 by Mike McCrea, on Flickr

P2100003 by Mike McCrea, on Flickr

The RX Explorer solo finally returned to the shop. And went up onto the racks; I had other canoes in the works.

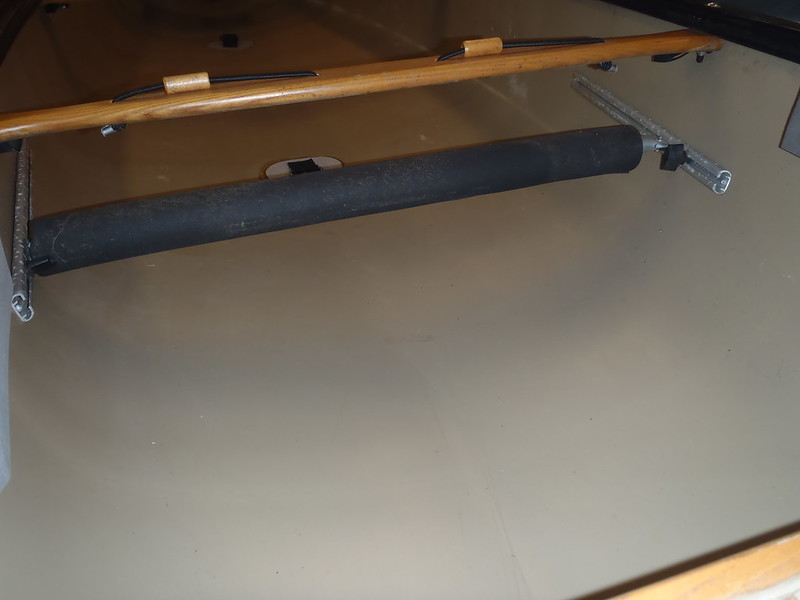

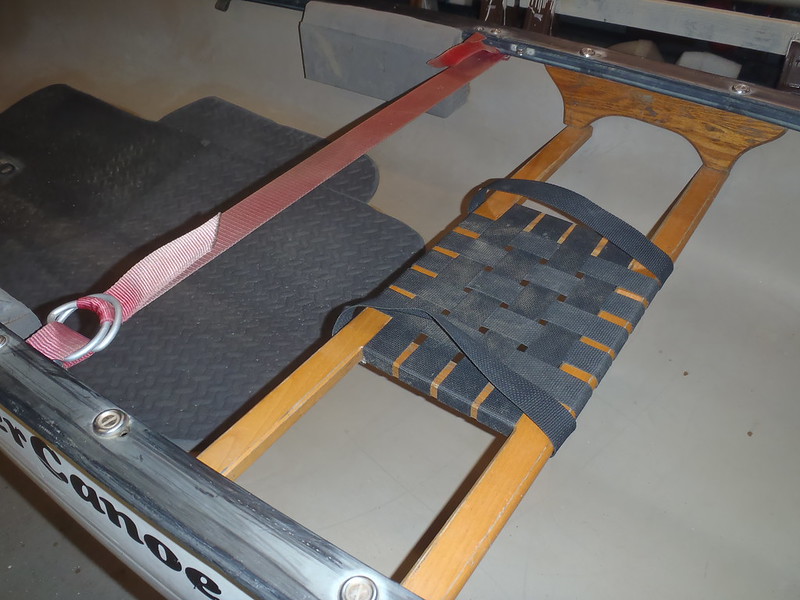

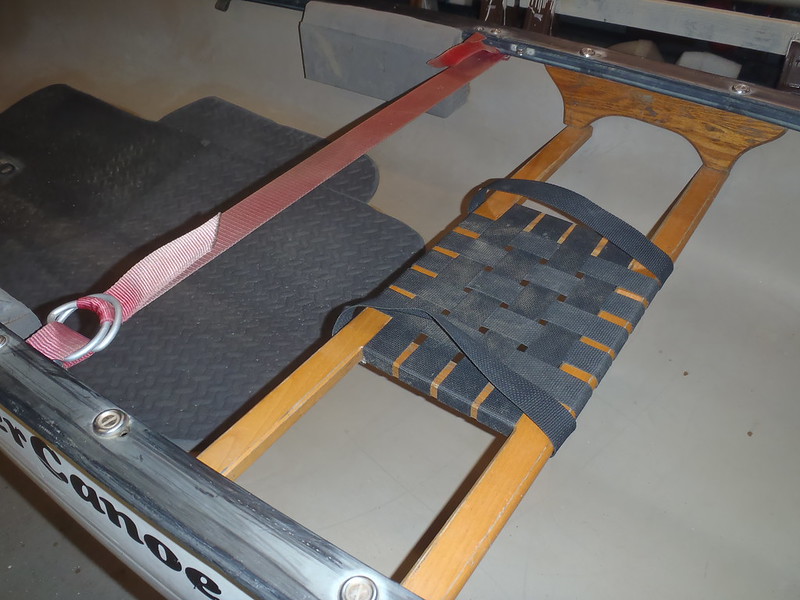

It finally came down for some finishing work. The Explorer is already a nicely appointed and decorated canoe. Strap yoke (note the double D-ring strap connection, proven to hold even a 70+ lb canoe) and truss hung seat with padding straps, knee bumpers, deck and thwart bungees.

P2100009 by Mike McCrea, on Flickr

P2100009 by Mike McCrea, on Flickr

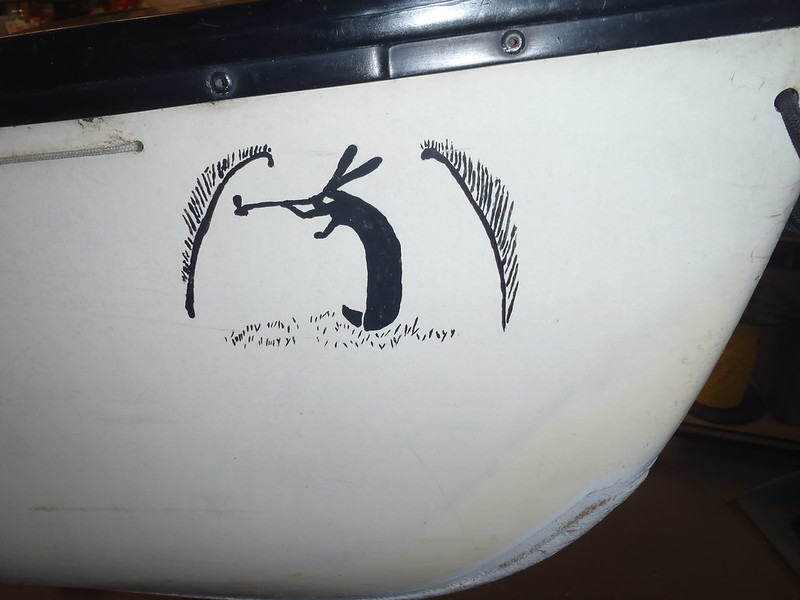

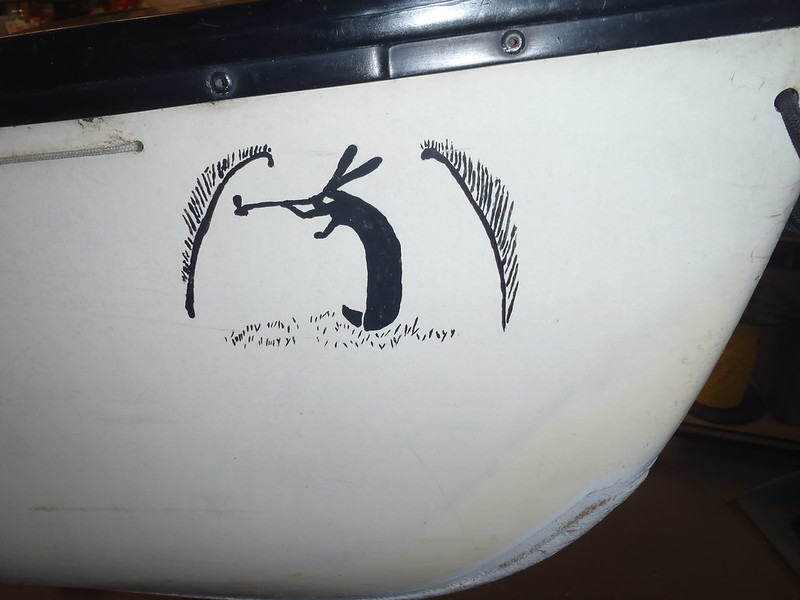

And some personalized stem decorations; a recreation of Chief Tomah Joseph’s original bunny in the ferns and usual Shop Gogetch.

P2100005 by Mike McCrea, on Flickr

P2100005 by Mike McCrea, on Flickr

P2100007 by Mike McCrea, on Flickr

P2100007 by Mike McCrea, on Flickr

The bungee cord is on its last legs, and it needs an adjustable foot brace. And, eh, a solo seat utility sail thwart.

I have a bunch of easy outfitting work to do. Unfortunately first starting with hauling that (I’m guessing) 75 lb beast into the shop, realizing that it was too muddy/sandy inside and out to work on, hauling it back outside to wash in 40F weather and bringing it once again back inside. Seventy some effing pounds in and out and back in. Accent on the “back” in spinal connotation. But it’s a piece of mid-1980’s Royalex history, when men were men and carried absurdly heavy 16’ canoes.

Maybe 75 lbs on the unwashed carries; there must have been 5 lbs of sand, grit and gravel lodged in that canoe, some of which I needed to pick out with foreceps. Borrower friend never washed it. Actually, for the last year+ he kept it on his van between trips.

I wasn’t even done with the re-outfitting when he stopped by and it headed up the driveway on loan; the gaps between the pieces of exercise flooring hiding sundry old adhesive smutch were filled level with sand, mud and pebbles.

This time I remembered to weigh it before starting any other re-outfitting work. With one center seat on thick DIY truss drops, two thwarts, three pieces of minicel padding, four vinyl pad D-rings and no partridge in a pear tree it weights in right at. . . . .

P2140012 by Mike McCrea, on Flickr

P2140012 by Mike McCrea, on Flickr

. . . . . . 80 freaking Lbs.

It’s not gonna get any lighter, unless I chisel of the stupid 5 lbs kevlar felt skid plates the original owner installed and replace them with a layer of Dynel. And I am tempted to do just that.

But first it needs a foot brace, and a utility sail thwart.

A Vermont-era RX canoe, with some seriously substantial Royalex. It has a memorable used-boat history; someone was looking for a bit of a do-everything used canoe. The RX Explorer came up for short money ($200) and I hurried to send them to the seller.

The potential buyer took a look and passed because one cane seat was busted out. OK then dummy, in that case it’s all mine. Other than the busted cane the canoe was in excellent condition. I no-dicker handing the guy four $50’s, and while I was racking it he started bringing out other throw-in freebies.

Two Voyageur paddles, two Clement paddles, a boat cart, a tee-bar for a receiver hitch, a side-motor mount, some decent PFD’s. I had started to tie on and drive away like I stole it, but changed my mind and took my time as he kept bringing freebies out.

Originally rebuilt as a center seat solo with kneeling thwart poling boat (with a hidden sail mount) for my older son’s proclivities it was soon displaced by lighter hulls. MRC speced it in Royalex at 72 lbs in the 1994 catalog, which was in later/lighter/less robust RX, and even center seat soloized it seemed every bit of that and then some.

I brought it into the shop a couple of years ago and began stripping it down, losing the padded kneeling thwart and adding some exercise flooring to cover old minicel padding smutch residue left on the floor from two or three past outfittings.

Mid-way through that re-re-built a poling friend stopped by, and I sent him home with the (unfinished) RX Explorer. His then-current poling boat was a 3-seater, yoke and thwarted glass/kev Explorer I rebuilt years ago, and there was no room between seats and thwarts to move around. The yet unfinished RX Explorer had almost 5 feet of walk around room between the solo seat and front thwart with the kneeling thwart removed.

The RX Explorer solo finally returned to the shop. And went up onto the racks; I had other canoes in the works.

It finally came down for some finishing work. The Explorer is already a nicely appointed and decorated canoe. Strap yoke (note the double D-ring strap connection, proven to hold even a 70+ lb canoe) and truss hung seat with padding straps, knee bumpers, deck and thwart bungees.

And some personalized stem decorations; a recreation of Chief Tomah Joseph’s original bunny in the ferns and usual Shop Gogetch.

The bungee cord is on its last legs, and it needs an adjustable foot brace. And, eh, a solo seat utility sail thwart.

I have a bunch of easy outfitting work to do. Unfortunately first starting with hauling that (I’m guessing) 75 lb beast into the shop, realizing that it was too muddy/sandy inside and out to work on, hauling it back outside to wash in 40F weather and bringing it once again back inside. Seventy some effing pounds in and out and back in. Accent on the “back” in spinal connotation. But it’s a piece of mid-1980’s Royalex history, when men were men and carried absurdly heavy 16’ canoes.

Maybe 75 lbs on the unwashed carries; there must have been 5 lbs of sand, grit and gravel lodged in that canoe, some of which I needed to pick out with foreceps. Borrower friend never washed it. Actually, for the last year+ he kept it on his van between trips.

I wasn’t even done with the re-outfitting when he stopped by and it headed up the driveway on loan; the gaps between the pieces of exercise flooring hiding sundry old adhesive smutch were filled level with sand, mud and pebbles.

This time I remembered to weigh it before starting any other re-outfitting work. With one center seat on thick DIY truss drops, two thwarts, three pieces of minicel padding, four vinyl pad D-rings and no partridge in a pear tree it weights in right at. . . . .

. . . . . . 80 freaking Lbs.

It’s not gonna get any lighter, unless I chisel of the stupid 5 lbs kevlar felt skid plates the original owner installed and replace them with a layer of Dynel. And I am tempted to do just that.

But first it needs a foot brace, and a utility sail thwart.