- Joined

- Jul 25, 2012

- Messages

- 838

- Reaction score

- 22

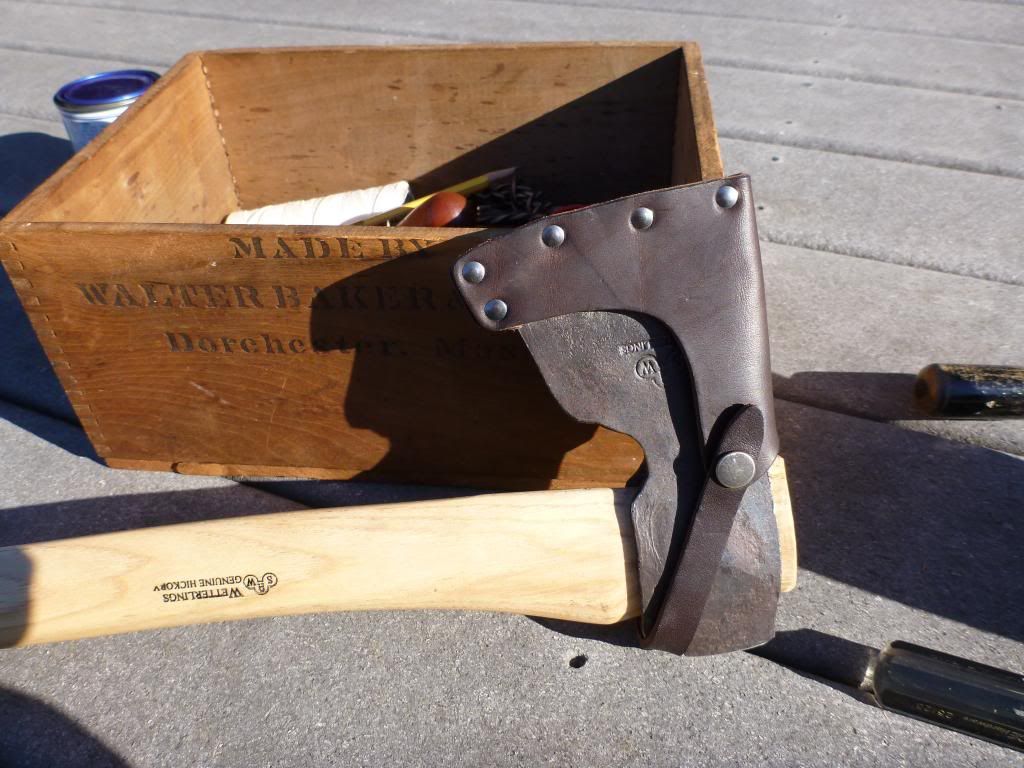

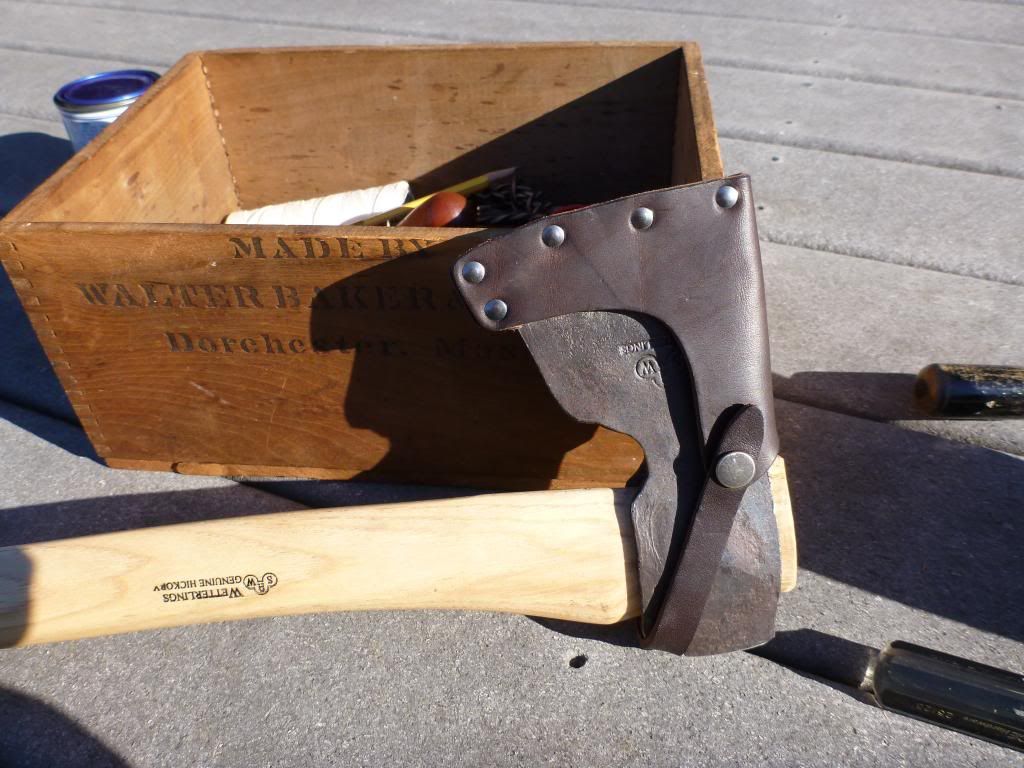

I was checking out gear on the internet the other day and I ran across the Wetterlings Forester's Axe. Intriguing idea; a very much smaller axe than what I normally use, but still an axe and not a hatchet. Depending on who is doing the review the head is somewhere around a pound and a half. The length is listed as 24", mine measures at 23 1/2".

The feature that caught my eye was the curved cutout for your finger when holding the head up close for fine work.

I tried a little fine work and I did see how gripping it up closer would be an advantage.

On the Wetterlings web site they have a video of how the axe heads are made by hand in a massive press. Not a job that would allow much day-dreaming.

The axe handle has no steel wedges in it and is allowed to extend past the head just a little bit; as you can see it flairs out and acts, I would guess, to help hold the head on. I believe the next time I replace an axe handle I'll try it their way.

The grain in the handle is darn good, not prefect, but for a production axe better than most.

The axe comes with a sheath, it's workable but a little lacking in my opinion. Maybe the guy who designed it spent too much time at the beach looking at the gals in bikinis (if such a thing is possible) it covers what's necessary but no more than that, pretty much like the famous swimsuit.

Given that I really try to avoid getting cut, I made one on my own. Since everything is so small I couldn't use the boot lace closure that I normally use, so snaps it is.

I did read all the reviews, but until I could hold it and see how it was to chop with it just didn't sink in how darn small the axe is; for me anyway too small.

I did give it a good testing and can report that it cuts very well: not that I expected it to come loose, but the head is still tight on the handle. For me though about a 28" handle ought to be just about prefect. It's too bad, it fits inside my larger camping box.

Best Wishes, Rob

The feature that caught my eye was the curved cutout for your finger when holding the head up close for fine work.

I tried a little fine work and I did see how gripping it up closer would be an advantage.

On the Wetterlings web site they have a video of how the axe heads are made by hand in a massive press. Not a job that would allow much day-dreaming.

The axe handle has no steel wedges in it and is allowed to extend past the head just a little bit; as you can see it flairs out and acts, I would guess, to help hold the head on. I believe the next time I replace an axe handle I'll try it their way.

The grain in the handle is darn good, not prefect, but for a production axe better than most.

The axe comes with a sheath, it's workable but a little lacking in my opinion. Maybe the guy who designed it spent too much time at the beach looking at the gals in bikinis (if such a thing is possible) it covers what's necessary but no more than that, pretty much like the famous swimsuit.

Given that I really try to avoid getting cut, I made one on my own. Since everything is so small I couldn't use the boot lace closure that I normally use, so snaps it is.

I did read all the reviews, but until I could hold it and see how it was to chop with it just didn't sink in how darn small the axe is; for me anyway too small.

I did give it a good testing and can report that it cuts very well: not that I expected it to come loose, but the head is still tight on the handle. For me though about a 28" handle ought to be just about prefect. It's too bad, it fits inside my larger camping box.

Best Wishes, Rob