G

Guest

Guest

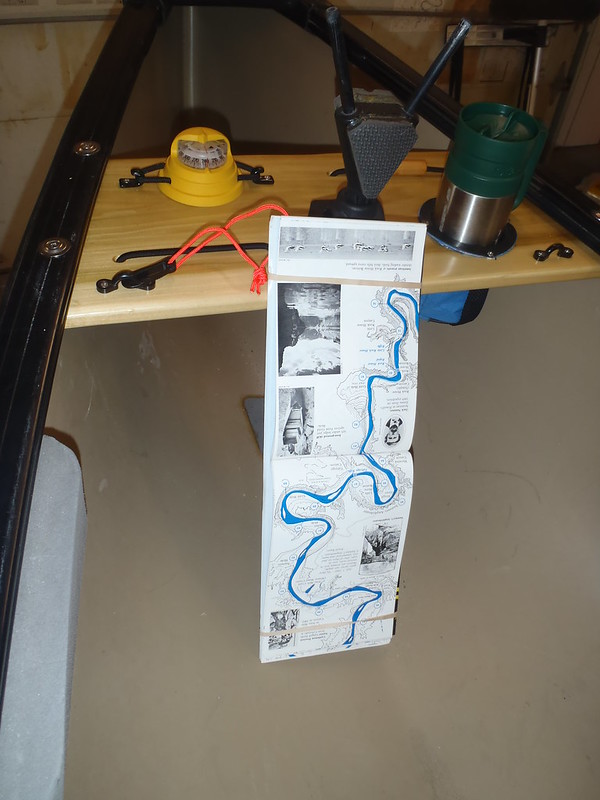

We have a utility thwart (sail mount, compass mount, map case hooks, lateral bungee to tuck misc gear under, etc) in front of the center seat in almost all of our solo boats. Early on I made them more Dr. Seuss shapely.

PB081336 by Mike McCrea, on Flickr

PB081336 by Mike McCrea, on Flickr

But decided that wider was more accommodating

P1220461 by Mike McCrea, on Flickr

P1220461 by Mike McCrea, on Flickr

And eventually went simply using to a straight length of 5 ½” wood, with more space for a mounted compass, which is good when map reading and a huge boon when sailing.

None of our big tandem boats have utility thwarts; we just don’t paddle tandem anymore and I never thought to provide one up front for bowman use.

Having hauled the 20 foot Miramichi into the shop to re-install the third seat it was time to stumble down another experimental outfitting road, installing a permanent utility sail thwart in front of the bow seat. I thought about making another custom sized clamp-on, we have a couple spares.

PC071385 by Mike McCrea, on Flickr

PC071385 by Mike McCrea, on Flickr

But have come to appreciate the function of those utility/sail thwarts so much that I know I want one always available, and not “Oh hell, I forgot to bring it”.

I typically make solo canoe utility thwarts 5 ½ inches wide to accommodate a downwind sail mount and other outfitting geegaws, including a compass, but I can foresee enhanced width function in a narrower bow paddler platform. The canoe already weighs 110 lbs, what’s another pound or two; go big or go home. Or go out to the shop.

A 9 ½ inch wide utility thwart should provide plenty of outfitting expanse. First, a template cut from scrap lauan to get the size, angle and fit right before I cut any good wood.

On solo canoes I install the utility thwart at an ample leg, knee and reach comfortable, 20-22 inches from the front of the seat edge on solo boats, but with a bowman able to lean further forward while the stern is in control of the canoe, I can comfortable put the utility thwarts a few inches further forward.

That’ll do, 25 inches away from the front edge of seat, plenty of room for even lanky folk’s legs or for kneeling, and still within reach when leaning forward.

Run the edges through the router, a little sanding and drill some holes for the machine screw hardware. I am not a fan of brightwork fitted tight against the edges of the hull. The butt ends never get any air to dry out, and sometimes that tightly fit stuff squeaks.

Some tongue depressors (Craft Sticks) taped temporarily on the butt ends provides an evenly spaced 1/16” gap on either side before drilling holes for the machine screws.

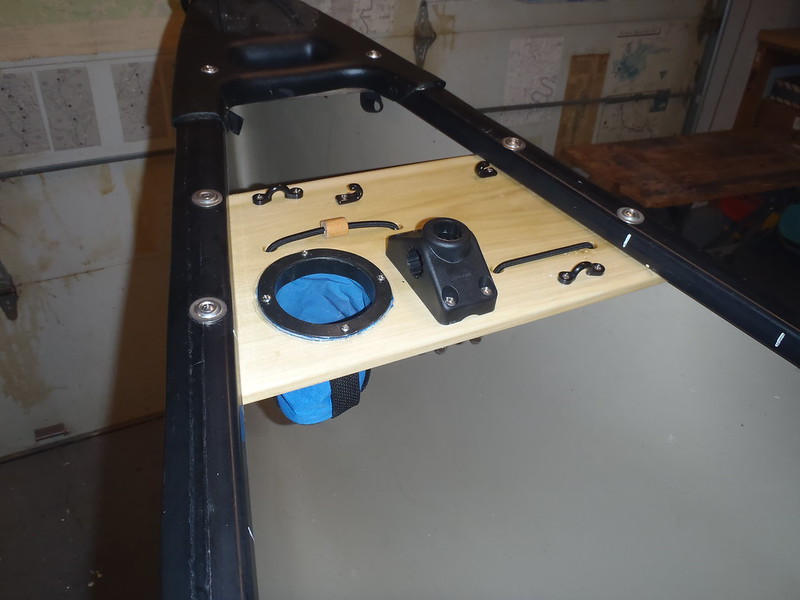

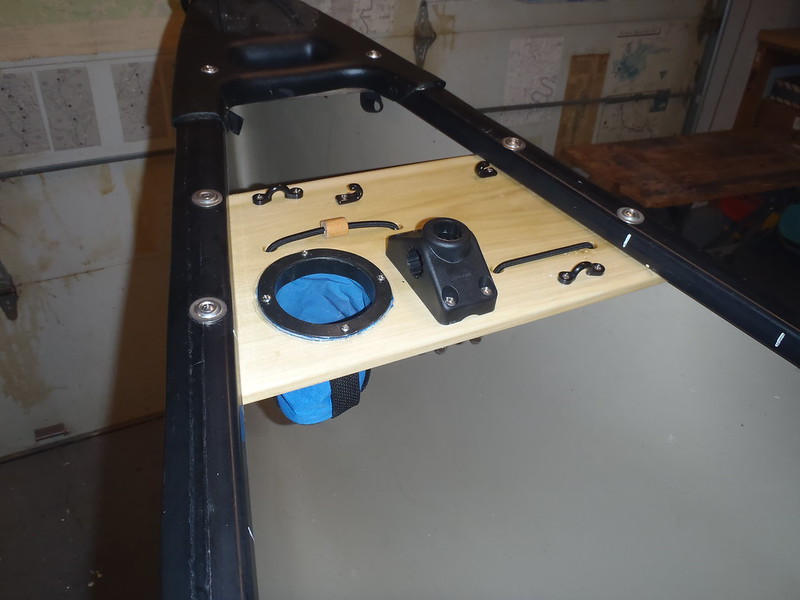

Double hung with two machine screws on each side; this utility thwart may need to withstand some sail stress. Through-inwale machine screws and flange washers temporarily installed. Time to position some outfitting in place. First and foremost, a centered base mount for a downwind Spirit Sail.

It’s a big boat (20’ long x 40” wide), it could use a big sail, and I have a large size (23.6 sf or 2.2 sqm) Spirit Sail. The large size has proven to be too much of a handful in a solo boat, at least in anything more than the lightest of winds, and that large size SS has scared the crap outa me a couple times when the wind picked up while in a solo canoe.

But it should move a big freighter along comfortably. Especially if the sail is the responsibility of the hands-free bowman while the stern attends to business. Time to figure out what else beside a sail mount I want placed where on the utility thwart, and then drill some more holes

In our solo canoes the 5 ½ inch wide utility thwarts are twice as long side to side, and even then they get crowded. With only 14 inches of thwart length in the bow I needed the extra width to fit all of the usual (and unusual) accoutrements in place

Spirit Sail base mount (which is a Scotty rod base, so the utility thwart could also be used for fishing), deck hooks to hold a compass and a run of over/under/over bungee cord for hat/gloves/sunglasses. The under bungee is handy for holding things kept out of the rain, and it is easier to pull taut and re-knot a single run of bungee than pull and re-knot tighten two short pieces when the bungee stretches out.

A couple of pad eyes to securely clip things to (map case, ditty bag) are always handy, with room left for a, um, circular void I have in bowman mind.

Coat of epoxy, including swabbing inside all of the through holes (drilled 1/64 larger than the hardware). Wait a few days, 220 wet sand, a couple coats of spar urethane, dress the utility thwart with the outfitting and reinstall.

PC071392 by Mike McCrea, on Flickr

PC071392 by Mike McCrea, on Flickr

PC071388 by Mike McCrea, on Flickr

PC071388 by Mike McCrea, on Flickr

I like it. I like the bowman beverage holder. It doesn’t come close to the 14 cup holders in a Mad River Adventure 16

https://www.google.com/search?sourc...0....1..gws-wiz.....0..0i131j0i10.bcIz2NKZzfQ

But one is enough. I added some 1” webbing straps under that beverage holder for durability sake, so the mesh bottom and nylon sleeve is not holding all the weight of a 40 ouncer.

PC071391 by Mike McCrea, on Flickr

PC071391 by Mike McCrea, on Flickr

Simple, easy and zero trips to the hardware store; I had all of the parts and pieces in shop stock. Come spring that beast is going on Craigslist, with the utility thwart and large Spirit Sail included. Custom welded aluminum motor mount, lee board and Wheel-a-Weigh Heavy Lifter cart optional.

One stroke of luck, the third (wide/heavy duty Ed’s Canoe) seat & hangers I installed had made the canoe a little stern heavy when under the yoke. The weight of the utility thwart in the bow balances it back out. Yeahhh, just like I planned it that way.

The bow utility thwart with attached accessories weighs 1.5 lbs. Oh gawd, now the Miramichi weighs 111.5 lbs. Maybe the heavy duty portage cart should be included in that sale.

I think I’ll install a bow utility thwart on the Mad River Revelation before that one goes up for sale come spring. Or not for sale, I may go all-in on outfitting that canoe and give it to some paddling inlaws.

PB081336 by Mike McCrea, on Flickr

PB081336 by Mike McCrea, on FlickrBut decided that wider was more accommodating

P1220461 by Mike McCrea, on Flickr

P1220461 by Mike McCrea, on FlickrAnd eventually went simply using to a straight length of 5 ½” wood, with more space for a mounted compass, which is good when map reading and a huge boon when sailing.

None of our big tandem boats have utility thwarts; we just don’t paddle tandem anymore and I never thought to provide one up front for bowman use.

Having hauled the 20 foot Miramichi into the shop to re-install the third seat it was time to stumble down another experimental outfitting road, installing a permanent utility sail thwart in front of the bow seat. I thought about making another custom sized clamp-on, we have a couple spares.

PC071385 by Mike McCrea, on Flickr

PC071385 by Mike McCrea, on FlickrBut have come to appreciate the function of those utility/sail thwarts so much that I know I want one always available, and not “Oh hell, I forgot to bring it”.

I typically make solo canoe utility thwarts 5 ½ inches wide to accommodate a downwind sail mount and other outfitting geegaws, including a compass, but I can foresee enhanced width function in a narrower bow paddler platform. The canoe already weighs 110 lbs, what’s another pound or two; go big or go home. Or go out to the shop.

A 9 ½ inch wide utility thwart should provide plenty of outfitting expanse. First, a template cut from scrap lauan to get the size, angle and fit right before I cut any good wood.

On solo canoes I install the utility thwart at an ample leg, knee and reach comfortable, 20-22 inches from the front of the seat edge on solo boats, but with a bowman able to lean further forward while the stern is in control of the canoe, I can comfortable put the utility thwarts a few inches further forward.

That’ll do, 25 inches away from the front edge of seat, plenty of room for even lanky folk’s legs or for kneeling, and still within reach when leaning forward.

Run the edges through the router, a little sanding and drill some holes for the machine screw hardware. I am not a fan of brightwork fitted tight against the edges of the hull. The butt ends never get any air to dry out, and sometimes that tightly fit stuff squeaks.

Some tongue depressors (Craft Sticks) taped temporarily on the butt ends provides an evenly spaced 1/16” gap on either side before drilling holes for the machine screws.

Double hung with two machine screws on each side; this utility thwart may need to withstand some sail stress. Through-inwale machine screws and flange washers temporarily installed. Time to position some outfitting in place. First and foremost, a centered base mount for a downwind Spirit Sail.

It’s a big boat (20’ long x 40” wide), it could use a big sail, and I have a large size (23.6 sf or 2.2 sqm) Spirit Sail. The large size has proven to be too much of a handful in a solo boat, at least in anything more than the lightest of winds, and that large size SS has scared the crap outa me a couple times when the wind picked up while in a solo canoe.

But it should move a big freighter along comfortably. Especially if the sail is the responsibility of the hands-free bowman while the stern attends to business. Time to figure out what else beside a sail mount I want placed where on the utility thwart, and then drill some more holes

In our solo canoes the 5 ½ inch wide utility thwarts are twice as long side to side, and even then they get crowded. With only 14 inches of thwart length in the bow I needed the extra width to fit all of the usual (and unusual) accoutrements in place

Spirit Sail base mount (which is a Scotty rod base, so the utility thwart could also be used for fishing), deck hooks to hold a compass and a run of over/under/over bungee cord for hat/gloves/sunglasses. The under bungee is handy for holding things kept out of the rain, and it is easier to pull taut and re-knot a single run of bungee than pull and re-knot tighten two short pieces when the bungee stretches out.

A couple of pad eyes to securely clip things to (map case, ditty bag) are always handy, with room left for a, um, circular void I have in bowman mind.

Coat of epoxy, including swabbing inside all of the through holes (drilled 1/64 larger than the hardware). Wait a few days, 220 wet sand, a couple coats of spar urethane, dress the utility thwart with the outfitting and reinstall.

PC071392 by Mike McCrea, on Flickr

PC071392 by Mike McCrea, on Flickr PC071388 by Mike McCrea, on Flickr

PC071388 by Mike McCrea, on FlickrI like it. I like the bowman beverage holder. It doesn’t come close to the 14 cup holders in a Mad River Adventure 16

https://www.google.com/search?sourc...0....1..gws-wiz.....0..0i131j0i10.bcIz2NKZzfQ

But one is enough. I added some 1” webbing straps under that beverage holder for durability sake, so the mesh bottom and nylon sleeve is not holding all the weight of a 40 ouncer.

PC071391 by Mike McCrea, on Flickr

PC071391 by Mike McCrea, on FlickrSimple, easy and zero trips to the hardware store; I had all of the parts and pieces in shop stock. Come spring that beast is going on Craigslist, with the utility thwart and large Spirit Sail included. Custom welded aluminum motor mount, lee board and Wheel-a-Weigh Heavy Lifter cart optional.

One stroke of luck, the third (wide/heavy duty Ed’s Canoe) seat & hangers I installed had made the canoe a little stern heavy when under the yoke. The weight of the utility thwart in the bow balances it back out. Yeahhh, just like I planned it that way.

The bow utility thwart with attached accessories weighs 1.5 lbs. Oh gawd, now the Miramichi weighs 111.5 lbs. Maybe the heavy duty portage cart should be included in that sale.

I think I’ll install a bow utility thwart on the Mad River Revelation before that one goes up for sale come spring. Or not for sale, I may go all-in on outfitting that canoe and give it to some paddling inlaws.