I'm not so sure I can find a willing volunteer for that job.Very interesting. I have no experience to offer, but as to this . . .

. . . unless there is some special tool or jig or clever trick available, maybe you need two people for the hard-to-reach nails—an iron holder and a hammer tapper.

-

Happy Birthday, Beethoven (1770-1827)! 🎼 5️⃣ , 9️⃣

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Refinishing Unglassed Furesø wood canoe

- Thread starter Sabs

- Start date

In doing some research on this sealing compound, it seems the common pretreatment for using it is a penetrating epoxy sealer that gets absorbed into the wood. Looks like a two part epoxy, that is thinner than laminating epoxy. Is there a reason this is not the preferred method to boat soup? Seems to be the same idea minus the oil. Does this just make future repairs near impossible because it's too hard?

Also I've found some other boat soup recipes on this forum woodenboat.com

Seems to be rather hard to find boiled linseed oil in Denmark, plenty of raw though, but I want it to dry this century.

sabs

Also I've found some other boat soup recipes on this forum woodenboat.com

Seems to be rather hard to find boiled linseed oil in Denmark, plenty of raw though, but I want it to dry this century.

sabs

Last edited:

At the end of this WCHA thread, in which poster alick burt over a few years tries swelling the wood and using many coats of varnish, he finally tries the Geoffrey Burke procedure with apparent success.

forums.wcha.org

forums.wcha.org

Another poster in the thread says he is going to try to seal the crevices with wood flour mixed into the varnish, but I don't see him report any results.

She floats but leaks a survey does your all wood canoe leak?

Hello folks Having completed Felix's Canoe see "a find in the UK" I took her for a paddle and she leaked.It wasn't enough to cause alarm and was easily dealt with using a sponge but it got me thinking. Is this always going to be the case or will it be cured with more paddling soaking the...

Another poster in the thread says he is going to try to seal the crevices with wood flour mixed into the varnish, but I don't see him report any results.

Yes I've read his posts and blog. That was the second time he tried it, but the first time it fails. I'm not sure why his first boat soup attempt doesn't go well, but maybe he didn't hammer the nails the first time.At the end of this WCHA thread, in which poster alick burt over a few years tries swelling the wood and using many coats of varnish, he finally tries the Geoffrey Burke procedure with apparent success.

She floats but leaks a survey does your all wood canoe leak?

Hello folks Having completed Felix's Canoe see "a find in the UK" I took her for a paddle and she leaked.It wasn't enough to cause alarm and was easily dealt with using a sponge but it got me thinking. Is this always going to be the case or will it be cured with more paddling soaking the...forums.wcha.org

Another poster in the thread says he is going to try to seal the crevices with wood flour mixed into the varnish, but I don't see him report any results.

sabs

I get the sense that part of the reason for the BLO/tung oil mixture in the boat soup is to reduce the dryness of the old wood and restore a greater measure of moistness and flexibility into the wood—that is, for a much longer period than water soaking can do.In doing some research on this sealing compound, it seems the common pretreatment for using it is a penetrating epoxy sealer that gets absorbed into the wood. Looks like a two part epoxy, that is thinner than laminating epoxy. Is there a reason this is not the preferred method to boat soup? Seems to be the same idea minus the oil.

It also occurred to my non-experienced mind to use coats of penetrating epoxy on the outside and inside after using the boat soup, as a way to seal in the oils and help "dam up" the butt joints (which would seem to be harder to dam up than lapped joints). After the epoxy, several coats of varnish would be applied to protect the epoxy from UV degradation and to further dam up the joints.

I also saw the video using this penetrating epoxy:

Penetrating Epoxy Sealer

Our low-viscosity clear penetrating epoxy sealer preserves, protects, and repairs wood. Use it to restore damaged, rotten wood or to seal new wood. Environmentally friendly formula contains no harm…

www.totalboat.com

www.totalboat.com

I think I will skip the epoxy. I know how hard that can be to sand back if needed. I don't mind keeping up with a yearly varnish.

Currently I'm looking into this sealing compound situation. I'm quite convinced that the boat was made with red lead putty sealing in the seams, but I'm pretty sure red lead powder will be hard to come by. I can find linseed oil putty, but it says you can't varnish over it which is concerning. And new sealing compounds don't stick to wood as they do to epoxy sealed wood.

Also it seems that the correct fix is to redo the cotton caulking before applying new putty. That is pretty daunting too. Oh boy...

sabs

Currently I'm looking into this sealing compound situation. I'm quite convinced that the boat was made with red lead putty sealing in the seams, but I'm pretty sure red lead powder will be hard to come by. I can find linseed oil putty, but it says you can't varnish over it which is concerning. And new sealing compounds don't stick to wood as they do to epoxy sealed wood.

Also it seems that the correct fix is to redo the cotton caulking before applying new putty. That is pretty daunting too. Oh boy...

sabs

I sense from WCHA threads that many paddlers who have these kinds of boats simply live with a little leaking.

I'd plop the canoe in the water, get in, paddle for two hours, see exactly where it leaks, and mark off those places. Then, perhaps focus on those areas with the tightening, cottoning, caulking and sealing methods you've been researching, in addition to boat souping and varnishing the entire hull.

Just another thought.

I'd plop the canoe in the water, get in, paddle for two hours, see exactly where it leaks, and mark off those places. Then, perhaps focus on those areas with the tightening, cottoning, caulking and sealing methods you've been researching, in addition to boat souping and varnishing the entire hull.

Just another thought.

Considering the outside of the boat was wet after washing the inside, I can skip the trip around the lake to find the leaks

I've read a lot about people using sponges on the WCHA forum. I guess they don't know about the foot pumped bilge pump used by marathon kayakers. Hands free.

I would defer to those with experience in doing this !

But just cleaning and reclenching the tacks, doesn't sound like it would take up the gaps.

I also think a method that is less permanent than say epoxy. Something that could be redone, if needed later on !

That's why I suggested oil.

Watco in my experience on my wood gunnels, is better than Helsman's similar product.

The video previously shared, is from a far more experienced builder, in that field than !

Looking forward to see, what you end up doing !

But just cleaning and reclenching the tacks, doesn't sound like it would take up the gaps.

I also think a method that is less permanent than say epoxy. Something that could be redone, if needed later on !

That's why I suggested oil.

Watco in my experience on my wood gunnels, is better than Helsman's similar product.

The video previously shared, is from a far more experienced builder, in that field than !

Looking forward to see, what you end up doing !

So, I've spoken to some local boat builders and it "seams" like there are more than one way to skin this cat.

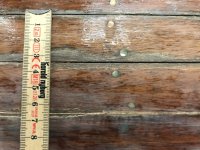

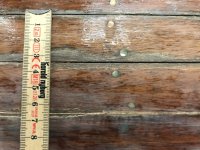

I've been told not to reclench the nails unless I plan to sand the entire boat down to the wood, inside and out since I am likely to crack any finish that is in the gaps, and I won't be able to get the hammer marks out unless I can put wet towels on the raw wood. This makes sense to me. Also the nails seem tight, and not protruding on the inside much past the wood, so it looks like I would need to put something much smaller than a piece of sledge hammer against them to tighten them up. Doing it that way, since the wood is proud of the nails, I could in fact loosen the nail by setting the inside flush with the wood. Don't want that.

Then I scraped some seams to see what was in there. Looks like it's oakum not cotton. It looks pretty rough.

But some of the seams look like they're empty.

And some that are still fine look even tighter.

So today I'm off to a boatyard to try to find some materials and ask if there is a point in adding cotton to such fine seams, or if I need to replace the oakum that is already in there.

My hope is that I can just prime the seams with oil, put new putty in and varnish over it.

Sabs

I've been told not to reclench the nails unless I plan to sand the entire boat down to the wood, inside and out since I am likely to crack any finish that is in the gaps, and I won't be able to get the hammer marks out unless I can put wet towels on the raw wood. This makes sense to me. Also the nails seem tight, and not protruding on the inside much past the wood, so it looks like I would need to put something much smaller than a piece of sledge hammer against them to tighten them up. Doing it that way, since the wood is proud of the nails, I could in fact loosen the nail by setting the inside flush with the wood. Don't want that.

Then I scraped some seams to see what was in there. Looks like it's oakum not cotton. It looks pretty rough.

But some of the seams look like they're empty.

And some that are still fine look even tighter.

So today I'm off to a boatyard to try to find some materials and ask if there is a point in adding cotton to such fine seams, or if I need to replace the oakum that is already in there.

My hope is that I can just prime the seams with oil, put new putty in and varnish over it.

Sabs

Geoff can help you with oakum or suppliers. Geoffrey Burke, Tamworth NH.. Google it. for contact info. He however will be leaving in a couple of days for the Wooden Canoe Heritage Association assembly in Paul Smiths for a week. He may have contacts your way as he has exported boats to Scandanavia.

So it's been a busy month. I ended up stripping the boat down to the bare wood.

The last person to re finish this boat made some pretty devastating errors I tried to remedy. I started by trying to sand some areas where the varnish was flaking but soon found that there was one layer of varnish that was readily coming off leaving a shiny surface underneath leading me to conclude that the last when the last few layers of varnish were applied, they were applied to a surface which had not been sanded beforehand.

So I started sanding and a few hours into it I realized the genius of a heat gun and spatula. The following day I scraped the other side of the boat where it became clear, due to the different finish of the nails, it had been refinished to the bare wood, as the varnish was significantly thinner. So someone had refinished one side and chose to varnish the whole boat.

Then as I began to clean out some of the areas where the red lead putty had cracked, I noticed that some seams had been filled with clear bathroom silicone, which was quite time consuming to dig out.

I recaulked a great many sections of the seams where it was clearly in need, by first applying oil into the empty seam (as some of the cotton cord was removed with the putty and others were just not really fully caulked) and then hammering in hemp cordage which I could unwind as I needed for the thickness of the gaps.

Due to the oil in the seams, much of which ran out (I was using a pipette to apply it) I ended up oiling the entire boat, which changed the colour of the wood quite a bit, to a much darker colour, but I think it looks rather nice. I also sanded and oiled the inside to get some of the "boat soup" going.

On the topic of oil, I bought a few liters of tung oil, but then I didn't use it because it was taking too long to dry. I was borrowing my workspace and was on a deadline, so instead I used kitchen counter oil, which was still a tung oil but had colbalt dryers added so it would dry in 24-48 hours depending on the thickness. I started with this before I did the caulking so it would have plenty of time to cure while I did the outside.

After caulking I investigated the putty situation. I visited many a wharf in the Copenhagen area and beyond and the two ideas were linseed oil putty for glazing windows, some kind of sika flex, or tar. It looks like some kind of tar or black sika product was used in some areas already, but I could not be sure what it was. I decided on keeping things original and opted for the linseed putty, but then panicked a bit when I realised it was quite the contrasting white to the now very dark mahogany boat.

This led me to the discovery of tar putty, which is a mixture of linseed oil, pine pitch tar (smells amazing) and bees wax. Now don't get ahead of me.

This stuff was really hard to use and was very sticky. Like getting fresh gum off your shoe. I was able to have some success by melting it with a heat gun so it would flow into some cracks and I could scrape off the excess but it wasn't working to well.

I then had the idea to tint the linseed oil putty to try and match the colour of the lead powder, so I bought red oil paint and mixed up a batch. A little goes a long way with that, and I was able to get a very nice shade. I knew there would be some dryers in the paint but since I was using so little it wouldn't have such a huge effect on the putty. I don't expect it to last another 50 years at any rate.

I then varnished the inside of the boat with Hempel classic varnish, which is a tung oil based clear varnish, and while I allowed that to dry I started coating the outside with the same. I wiped down the boat with terps to smooth out the putty seams, then with a 20% mixture I applied the first coat to the outside, for a total of 4 coats.

Now this might be the point where I catch up to you. The internet is a wonderful thing, but one thing it often lacks is consensus. Though I had a though earlier, and googled for the answer "can you varnish over bees wax" to which the answer was a resounding "yes" I didn't search for the more important question, "does bees wax inhibit varnish curing" to which the answer is also a resounding "yes". Luckily, I only did two seams with the tar putty, which turned out to be mostly bees wax, and is intended to be used to fill gaps in wood cabins and those farm houses where you can see the diagonal beams between the bricks, but is put on after paint or other finish.

Further research suggested that the driers in the varnish would save the problem with the second coat. Well maybe, but not after curing for a week at least.

I was short on time, so I had to break out the heat gun and scrape any seam where I had used it, remelting the wax and dabbing it up with paper, then scrubbing with turpentine, repeating until no more wax was flowing out and I couldn't scrape anymore. I then re filled those gaps with linseed putty and continued to varnish.

I let the varnish cure for a week and launched the boat on the windiest day you could imagine of course. But the next day everything was fine. Boat was floating, no leaks. Beautiful. Complements on it from everyone we passed on the lake. Mission accomplished.

Or so I thought, because after two weeks of the boat being in the harbour, when I last paddled it on a day it which had quite warm temperatures and no wind, I've sprung a leak. But to be more accurate, a large number of seams were weeping water into the boat as we paddled. It was heartbreaking. I think I would now say that "boat soup" is a synonym for "hogwash". It is after all just varnish with more oil thinned down, so just varnish. It's like saying an Arnold Palmer is a mixture of lemonade and iced tea, and not admitting that it's just lemon iced tea. But I digress.

The boat is out of the water now. Some of the seams have puckered from the oil and putty being squeezed out from the wood swelling a bit. I think I will lay on some more coats of varnish.

I think also I shouldn't have bothered with the oil based varnish, as it stays quite soft. Subsequent coats will be with a poly, which has synthetic oils. I should have used a two part varnish I think, but now it is too late since they are not compatible with one part varnishes. But If I end up stripping to bare wood again I will be using the two part stuff for sure.

Unrelated to the finish, I also discovered that the last owner has actually moved the rear seat from its original location to the very back as it is in the photos. Also the rear thwart was cut down and moved rearward, all to make more space for the foam bed mattress in the center of the boat. I can see the original location of the seat, since it used to sit on two beams of wood which were nailed in from the outside with the same clinch nails but longer. The front seat is still attached in this way. All that to say, sitting so far to the rear makes the boat unpaddleable alone, and very tippy when paddling with a partner. The boat has a V bottom so it is quite fast but as a result not so stable, and sitting low in the rear of the boat, with your knees way above your hips and no where to fold them because of that thwart makes the whole experience a bit disappointing. So I'll be rebuilding the rear seat to be as it was before it was 'modified' as well as possibly replacing the thwart if I can't use scarf joints to extend it to its original length. I think the boat being paddleable is more important than being able to lay down fully, which would actually be pretty hard due to the tippiness of the boat.

So that's the update. The work continues. I think I'll keep it out of the water for a little now while I build up some more layers of varnish. I think also it went in a bit prematurely, since some areas of the varnish below the unloaded water line were milky from the water penetrating the finish.

I might end up painting below the waterline if it happens after basically candy coating the whole boat in varnish inside and out. Thoughts welcome.

Sabs

The last person to re finish this boat made some pretty devastating errors I tried to remedy. I started by trying to sand some areas where the varnish was flaking but soon found that there was one layer of varnish that was readily coming off leaving a shiny surface underneath leading me to conclude that the last when the last few layers of varnish were applied, they were applied to a surface which had not been sanded beforehand.

So I started sanding and a few hours into it I realized the genius of a heat gun and spatula. The following day I scraped the other side of the boat where it became clear, due to the different finish of the nails, it had been refinished to the bare wood, as the varnish was significantly thinner. So someone had refinished one side and chose to varnish the whole boat.

Then as I began to clean out some of the areas where the red lead putty had cracked, I noticed that some seams had been filled with clear bathroom silicone, which was quite time consuming to dig out.

I recaulked a great many sections of the seams where it was clearly in need, by first applying oil into the empty seam (as some of the cotton cord was removed with the putty and others were just not really fully caulked) and then hammering in hemp cordage which I could unwind as I needed for the thickness of the gaps.

Due to the oil in the seams, much of which ran out (I was using a pipette to apply it) I ended up oiling the entire boat, which changed the colour of the wood quite a bit, to a much darker colour, but I think it looks rather nice. I also sanded and oiled the inside to get some of the "boat soup" going.

On the topic of oil, I bought a few liters of tung oil, but then I didn't use it because it was taking too long to dry. I was borrowing my workspace and was on a deadline, so instead I used kitchen counter oil, which was still a tung oil but had colbalt dryers added so it would dry in 24-48 hours depending on the thickness. I started with this before I did the caulking so it would have plenty of time to cure while I did the outside.

After caulking I investigated the putty situation. I visited many a wharf in the Copenhagen area and beyond and the two ideas were linseed oil putty for glazing windows, some kind of sika flex, or tar. It looks like some kind of tar or black sika product was used in some areas already, but I could not be sure what it was. I decided on keeping things original and opted for the linseed putty, but then panicked a bit when I realised it was quite the contrasting white to the now very dark mahogany boat.

This led me to the discovery of tar putty, which is a mixture of linseed oil, pine pitch tar (smells amazing) and bees wax. Now don't get ahead of me.

This stuff was really hard to use and was very sticky. Like getting fresh gum off your shoe. I was able to have some success by melting it with a heat gun so it would flow into some cracks and I could scrape off the excess but it wasn't working to well.

I then had the idea to tint the linseed oil putty to try and match the colour of the lead powder, so I bought red oil paint and mixed up a batch. A little goes a long way with that, and I was able to get a very nice shade. I knew there would be some dryers in the paint but since I was using so little it wouldn't have such a huge effect on the putty. I don't expect it to last another 50 years at any rate.

I then varnished the inside of the boat with Hempel classic varnish, which is a tung oil based clear varnish, and while I allowed that to dry I started coating the outside with the same. I wiped down the boat with terps to smooth out the putty seams, then with a 20% mixture I applied the first coat to the outside, for a total of 4 coats.

Now this might be the point where I catch up to you. The internet is a wonderful thing, but one thing it often lacks is consensus. Though I had a though earlier, and googled for the answer "can you varnish over bees wax" to which the answer was a resounding "yes" I didn't search for the more important question, "does bees wax inhibit varnish curing" to which the answer is also a resounding "yes". Luckily, I only did two seams with the tar putty, which turned out to be mostly bees wax, and is intended to be used to fill gaps in wood cabins and those farm houses where you can see the diagonal beams between the bricks, but is put on after paint or other finish.

Further research suggested that the driers in the varnish would save the problem with the second coat. Well maybe, but not after curing for a week at least.

I was short on time, so I had to break out the heat gun and scrape any seam where I had used it, remelting the wax and dabbing it up with paper, then scrubbing with turpentine, repeating until no more wax was flowing out and I couldn't scrape anymore. I then re filled those gaps with linseed putty and continued to varnish.

I let the varnish cure for a week and launched the boat on the windiest day you could imagine of course. But the next day everything was fine. Boat was floating, no leaks. Beautiful. Complements on it from everyone we passed on the lake. Mission accomplished.

Or so I thought, because after two weeks of the boat being in the harbour, when I last paddled it on a day it which had quite warm temperatures and no wind, I've sprung a leak. But to be more accurate, a large number of seams were weeping water into the boat as we paddled. It was heartbreaking. I think I would now say that "boat soup" is a synonym for "hogwash". It is after all just varnish with more oil thinned down, so just varnish. It's like saying an Arnold Palmer is a mixture of lemonade and iced tea, and not admitting that it's just lemon iced tea. But I digress.

The boat is out of the water now. Some of the seams have puckered from the oil and putty being squeezed out from the wood swelling a bit. I think I will lay on some more coats of varnish.

I think also I shouldn't have bothered with the oil based varnish, as it stays quite soft. Subsequent coats will be with a poly, which has synthetic oils. I should have used a two part varnish I think, but now it is too late since they are not compatible with one part varnishes. But If I end up stripping to bare wood again I will be using the two part stuff for sure.

Unrelated to the finish, I also discovered that the last owner has actually moved the rear seat from its original location to the very back as it is in the photos. Also the rear thwart was cut down and moved rearward, all to make more space for the foam bed mattress in the center of the boat. I can see the original location of the seat, since it used to sit on two beams of wood which were nailed in from the outside with the same clinch nails but longer. The front seat is still attached in this way. All that to say, sitting so far to the rear makes the boat unpaddleable alone, and very tippy when paddling with a partner. The boat has a V bottom so it is quite fast but as a result not so stable, and sitting low in the rear of the boat, with your knees way above your hips and no where to fold them because of that thwart makes the whole experience a bit disappointing. So I'll be rebuilding the rear seat to be as it was before it was 'modified' as well as possibly replacing the thwart if I can't use scarf joints to extend it to its original length. I think the boat being paddleable is more important than being able to lay down fully, which would actually be pretty hard due to the tippiness of the boat.

So that's the update. The work continues. I think I'll keep it out of the water for a little now while I build up some more layers of varnish. I think also it went in a bit prematurely, since some areas of the varnish below the unloaded water line were milky from the water penetrating the finish.

I might end up painting below the waterline if it happens after basically candy coating the whole boat in varnish inside and out. Thoughts welcome.

Sabs

Thoughts welcome.

That's quite an epic work project, Sabs. I have nothing constructive to offer except to utter three words you probably still don't want to consider: (fiberglass the outside).

Believe me, Glenn, it’s crossed my mind. But I’m pretty sure that if I only do the outside and not the inside as well I will have serious problems when the wood starts to move. And glassing the inside with the ribs probably won’t go the way I think.

But then, as an honest question, how is just glassing the outside different than a canvas covered canoe? Or is the canvas not glued down in that case?

Sabs

But then, as an honest question, how is just glassing the outside different than a canvas covered canoe? Or is the canvas not glued down in that case?

Sabs

Last edited:

Believe me, Glenn, it’s crossed my mind. But I’m pretty sure that if I only do the outside and not the inside as well I will have serious problems when the wood starts to move. And glassing the inside with the ribs probably won’t go the way I think.

But then, as an honest question, how is just glassing the outside different than a canvas covered canoe? Or is the canvas not glued down in that case?

Sabs

A rib and plank canoe can be covered with canvas, plus a brushed on filler that makes the canvas waterproof from the outside, plus paint on top of the filled canvas. The inside of the canoe—the planks and ribs—are just varnished. (Some builders, like Alex Comb of Stewart River Boatworks, will pre-seal the wood components with linseed oil before varnishing.)

Alternatively and a minority of times, rib and plank canoes are covered on the outside with fiberglass instead of canvas, filler an paint. The inside is still varnished. There is no need for interior fiberglass on a rib and plank canoe, as there is for strip built canoes, because the ribs provide the interior structural strength.

The benefit of a fiberglass exterior is that you can see the wood through it. The detriment is mostly that purists like canvas and paint for historical reasons. Also, completely removing fiberglass and resin is said by some to be more painstaking than removing canvas when it's time to restore the entire exterior. I've previously owned two Old Town wooden canoes with fiberglass exteriors. I like the look.

In your case, a fiberglass exterior and varnished interior should solve your leak problems. You could still see the exterior wood, but the wood-only purists in Denmark, perhaps including yourself, might sniff disdainfully while sipping akvavit.

Hang on there, Glenn. The problem with fiberglassing a wood canvas canoe with epoxy is that the glass will bond with the exterior wood. The interior wood, no matter how well it is varnished, will swell when it gets wet, and shrink when it dries. This will lead to planks fracturing and a host of other problems. This is the main reason wood/canvas guys poopoo the fiberglass, not so much about aesthetics.

Having said that, I put some thought into it, and took wide masking tape and taped the entire bare hull. Then I fiberglassed over it with ten ounce cloth. In this way, the wood does not bond to the fiberglass, so natural expansion and contraction can occur. It's only a theory I developed, but the canoe still looks great. I think someone else at canoetripping might have done this too, but they used saran wrap.

I have an old beater outside that I might try the saran wrap thing with. Even if you were to fiberglass to the hull directly, all of the cracks would have to be filled first. A barrier also gets rid of that problem.

Having said that, I put some thought into it, and took wide masking tape and taped the entire bare hull. Then I fiberglassed over it with ten ounce cloth. In this way, the wood does not bond to the fiberglass, so natural expansion and contraction can occur. It's only a theory I developed, but the canoe still looks great. I think someone else at canoetripping might have done this too, but they used saran wrap.

I have an old beater outside that I might try the saran wrap thing with. Even if you were to fiberglass to the hull directly, all of the cracks would have to be filled first. A barrier also gets rid of that problem.

I would personally never fiberglass a hull like that.

It seems you have some substantial voids between planking that would only be corrected with tightening the fasteners/planking.

If preserving the boat is as important to you as usability, I would consider paying a professional who is familiar with this type of construction. Just my two cents.

Bob

It seems you have some substantial voids between planking that would only be corrected with tightening the fasteners/planking.

If preserving the boat is as important to you as usability, I would consider paying a professional who is familiar with this type of construction. Just my two cents.

Bob

Hang on there, Glenn. The problem with fiberglassing a wood canvas canoe with epoxy is that the glass will bond with the exterior wood. The interior wood, no matter how well it is varnished, will swell when it gets wet, and shrink when it dries. This will lead to planks fracturing and a host of other problems.

Well, as I said, I've had two Old Town rib/plank canoes with fiberglass exteriors and varnished interiors, and none of those horribles ever happened. Maybe Old Town adds some additional steps that I'm not aware of.

Reading WCHA threads, it seems a fair number of amateur folks fiberglass the outside of their W/C canoes when they restore them, to the admitted chagrin of most of the WCHA members who participate in those threads.

Are there more voids between the planks of Sabs' boat than typical American rib/plank canoes? Maybe, not sure. Anyway, fiberglass is a solution that Sabs rejected early in this thread.

Similar threads

- Replies

- 14

- Views

- 882

- Replies

- 36

- Views

- 3K

- Replies

- 27

- Views

- 3K

- Replies

- 7

- Views

- 1K

- Replies

- 17

- Views

- 3K