I've installed PVC lining holes on Royalex canoes, but don't know about doing that on a Kevlar boat. Anyone done lining holes on a precious layup canoe?

-

Happy Cinco de Marcho! ⏱️1️⃣2️⃣⬅️☘️

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Layup Lining Holes

- Thread starter Black_Fly

- Start date

G

Guest

Guest

I've installed PVC lining holes on Royalex canoes, but don't know about doing that on a Kevlar boat. Anyone done lining holes on a precious layup canoe?

The original (discontinued) Tug-eyes had a version for composite hull use that somehow passed through and sealed (?) the floatation tanks.

I don’t recall exactly how those composite hull Tug-eyes were designed and can’t envision how to DIY lower lining holes through a floatation tank.

If you are putting simple painter line holes above the float tank we have those on several composite canoes and they are nothing special. Even the OEM ones are just a flanged plug, not even reinforced on the inside.

What adhesive would you use for rubber to layup adhesion?

Yes I have done it in Kevlar hulls. Drill hole to fit pvc pipe, epoxy the pvc in place, File and sand smooth. Hardest part is getting the nerve to dill into the hull and judging level and symmetrical.

I've put in PVC holes in fiberglass and Kevlar canoes, no problem (though there's some fuzz on Kevlar--maybe use a razor blade to clean up). I just used regular epoxy. One boat (fiberglass w/Kevlar reinforcement) has had them 35 years with no problems.

I have done as Dan and Mason describe on Kevlar and cedar strip boats. Start with a small drill bit and step up until you get to the right size. I used west or Raka epoxy and thickened it with some filler, but I'm not sure if that did any good. Use sandpaper to scuff up the pvc.

Mark

Mark

I'd start with a Long 1/4" drill bit, you can find them, a foot long, at most tool suppliers.

Pick a spot. Eye ball a 90 degree angle to the centerline.

Drill. The 1/4" will make a Pilot hole for a hole saw. Pick a hole saw the same outside diameter as the PVC you want to use. Drill through one side, and then go to the other side and drill. You should be closely lined up !

Yes, use epoxy with a lot of filler . Apply the filler to the inside if you can ( most commercial hulls have flotation that will hinder this.

Trim the PVC just a little bigger, to allow a surface for the filled epoxy to adhere to. Staying on the outside of the hull will add a little strength

I'm not a fan of PVC and epoxy bonding ! I'd much prefer a hard wood doll with a hole. And wet some cloth to cover the inside, and around the plug.

A better source on this is Nick Schade's Guillemot Kayaks ! I'm sure he has some videos !

This may help ?

https://www.youtube.com/watch?v=by06dnMP1_U

Jim

Pick a spot. Eye ball a 90 degree angle to the centerline.

Drill. The 1/4" will make a Pilot hole for a hole saw. Pick a hole saw the same outside diameter as the PVC you want to use. Drill through one side, and then go to the other side and drill. You should be closely lined up !

Yes, use epoxy with a lot of filler . Apply the filler to the inside if you can ( most commercial hulls have flotation that will hinder this.

Trim the PVC just a little bigger, to allow a surface for the filled epoxy to adhere to. Staying on the outside of the hull will add a little strength

I'm not a fan of PVC and epoxy bonding ! I'd much prefer a hard wood doll with a hole. And wet some cloth to cover the inside, and around the plug.

A better source on this is Nick Schade's Guillemot Kayaks ! I'm sure he has some videos !

This may help ?

https://www.youtube.com/watch?v=by06dnMP1_U

Jim

Last edited:

I wouldn't worry too much about it. In contrast to the care that Mark and Jim took with theirs, I drilled mine with a spade bit with no pilot, didn't roughen up the PVC, used hardware 15 min. epoxy, and mine look fine and last forever. For a lining hole, ideally you want the hole right at waterline to avoid torquing and potentially dumping the boat. I put mine a few inches above, but quite a bit lower than the photo you posted. The hole should be watertight with the epoxy, so you shouldn't have leaks wherever you put it. I also chamfered the PVC pipe a bit once installed to reduce the binding of the line going through, just making a smoother transition.

Thanks. I know I should have put them lower. Didn't have you guys on hand back then.

G

Guest

Guest

On Royalex hulls, where there is no floatation tank in the way, I have G/flexed flanged electrical conduit fittings on the outside through the holes drilled in the hull. No idea what that flange is called; in one of the electrical aisles at Home Depot. 1 1/8” outer diameter on the flange, 5/8” interior diameter on the painter line hole.

P5260015 by Mike McCrea, on Flickr

P5260015 by Mike McCrea, on Flickr

I capped the old stem-high holes, just for aesthetics.

For the sealed pass through inside I used a piece of (barely) flexible hose, also G/flexed sealed in place. The bit of tubing flexibility helps when cramming the hosed in place. Clamp the flanges from the outside on the stems; using a couple of \ wedges help with the clamps, keeping everything pressed firmly while the epoxy sets up

P5260016 by Mike McCrea, on Flickr

P5260016 by Mike McCrea, on Flickr

Can’t see from the photos but the ends of the electrical flanges protrude well past the RX inwalls.

I like the flange aspect of the electrical fitting, maybe more so on thin-walled UL composite boats to help spread the load.

I capped the old stem-high holes, just for aesthetics.

For the sealed pass through inside I used a piece of (barely) flexible hose, also G/flexed sealed in place. The bit of tubing flexibility helps when cramming the hosed in place. Clamp the flanges from the outside on the stems; using a couple of \ wedges help with the clamps, keeping everything pressed firmly while the epoxy sets up

Can’t see from the photos but the ends of the electrical flanges protrude well past the RX inwalls.

I like the flange aspect of the electrical fitting, maybe more so on thin-walled UL composite boats to help spread the load.

The original (discontinued) Tug-eyes had a version for composite hull use that somehow passed through and sealed (?) the floatation tanks.

I don’t recall exactly how those composite hull Tug-eyes were designed and can’t envision how to DIY lower lining holes through a floatation tank.

If you are putting simple painter line holes above the float tank we have those on several composite canoes and they are nothing special. Even the OEM ones are just a flanged plug, not even reinforced on the inside.

I think they're still available (edit: nevermind, old link). The so-called "yankee engineer" who designed them is someone I trip with, quite a character.

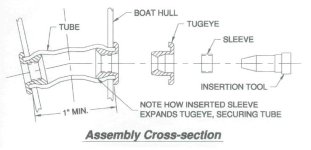

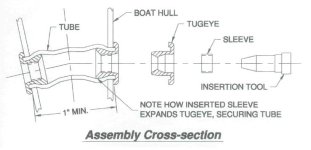

I've never done the through-the-float-chamber treatment. Only one of my composite canoes has float chambers, and on that one the above-the-tank location works well. This is the "Tugeye 2" diagram.

Attachments

Last edited:

- Joined

- Jan 7, 2016

- Messages

- 960

- Reaction score

- 1,885

"I'd much prefer a hard wood doll with a hole," to quote Jim Dodd, made me laugh, don't ya just love auto correct.

Well I'm a little intimidated by the float compartment. If tugeye kits were still available I might try it. I don't think the rigid pvc treatment would be satisfactory.

Last edited:

Well I'm a little intimidated by the float compartment. If tugeye kits were still available I might try it. I don't think the rigid pvc treatment would be satisfactory.

If you do it right, the epoxy will seal the junction. It ain't rocket surgery.

G

Guest

Guest

Thanks, that diagram brought back memories.

I put Tugeyes in an RX Wilderness that was dressed up with every imaginable manufactured component for a Pimp My Boat article. The process was easy and well explained in the instructions and diagrams.

The outer flange on those Tugeyes is what led me to use that conduit flange on DIY versions.

Last edited:

"I'd much prefer a hard wood doll with a hole," to quote Jim Dodd, made me laugh, don't ya just love auto correct.

I'm Blushing ! I knew I should have posted a picture !

Last edited:

I was able to order tugeye2 holes from that link Mike provided, although the webpage still denotes the www.tugeye.com address that doesn't work. I also was not redirected back to the website to confirm after using PayPal. Hopefully the order will process.

G

Guest

Guest

Goonstroke's link. I didn't even know Tugeyes were still available.

Well I don't know if I ordered or not. It didn't bounce me back to confirm order, no email receipt. All I know is my card was hit for $40. Hope it went through.

Similar threads

- Replies

- 0

- Views

- 135

- Replies

- 0

- Views

- 113