My mistake there was two fold. I forgot to hit that end with the heat gun and pre-twist plus I yarded down on it too hard to try to close the gap. With both of those forces together it was too much. So lucky that it appears to have turned out ok.

-

Happy Tell a Fairy Tale Day! 😺👢, 🔒🐻🐻❄️🐼, ❄️7️⃣

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kite +6%

- Thread starter BigandSmall

- Start date

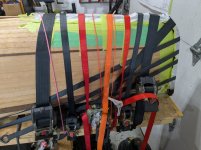

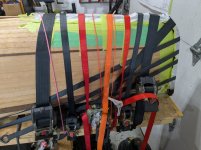

I used my oscillating tool to cut the channel as well as a sharp chisel then a file to clean it up. I then laminated in some tapered walnut pieces and once the glued dried planed/sanded them down level. I dry fit the stem laminations over night and epoxied them on today. I used unthickened epoxy between the strips and then added some wood flour for the joint to the hull. I used a bolt to the inner stem at the bottom to keep everything centered that will be cut off after. The wax paper is to keep the epoxy off my ratchet straps.

When I went to the stern to work on the channel there I went as far as I could until I can get a couple of more strips in. I'm trying to ensure that the stems follow the design curve of the hull. I looked at a everyone's build pictures ensuring mine looked pretty close before the laminations went on. I want to keep the handling as close to design as possible even though I mucked with things. Not having the right materials on hand has made the stems quite a pain. I'm looking forward to rough shaping them.

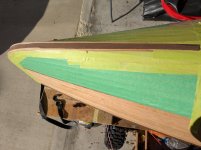

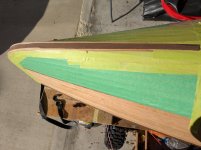

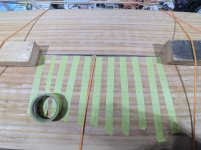

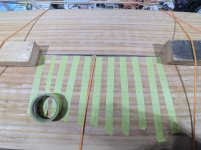

Since I'm on hold strip wise I decided to try out a new tool. I bought a cheap flexible long sanding board with a vacuum attachment a couple of weeks ago. With some 80 grit Abranet on there it's working pretty well. After a little test on the hull I'm just working on the overly thick walnut sheer strip taking it down flush. After taping all the holes up it's working ok connected to my little dust collector unit. It's nowhere near as "dust free" as my random orbital though.

When I went to the stern to work on the channel there I went as far as I could until I can get a couple of more strips in. I'm trying to ensure that the stems follow the design curve of the hull. I looked at a everyone's build pictures ensuring mine looked pretty close before the laminations went on. I want to keep the handling as close to design as possible even though I mucked with things. Not having the right materials on hand has made the stems quite a pain. I'm looking forward to rough shaping them.

Since I'm on hold strip wise I decided to try out a new tool. I bought a cheap flexible long sanding board with a vacuum attachment a couple of weeks ago. With some 80 grit Abranet on there it's working pretty well. After a little test on the hull I'm just working on the overly thick walnut sheer strip taking it down flush. After taping all the holes up it's working ok connected to my little dust collector unit. It's nowhere near as "dust free" as my random orbital though.

- Joined

- Aug 10, 2018

- Messages

- 2,170

- Reaction score

- 7,331

I'm liking the Walnut accents. Might have use some on the next build.

Black anodizing on gunnels? How easily does that stuff scratch off? While I prefer the look of the black I have Thule wing bars on my truck with just a small strip of rubber down the center. I'm sure there will be contact when loading. My current boat has vinyl on top with lots of scuff marks.

This is looking very nice! The accents are pulling together nicely, and that herringbone interleaving is also one of the nicer looking ways of doing it.

I finally got to spend a little more time on the boat. I used some 60 grit on my random orbital to rough shape the bow stem. I then used my long board with the 80 grit Abranet to get it level with the hull. When rough shaping I was missing just a tiny piece on the top profile. I might not need it but decided to build it up for a level starting point. I filed a bit more away so there was more room for the glue to bite. I glued in a small scrap then planed it down level. I suspect it will disappear when wet out.

I also laminated in 3 layers into the stern stem channel and will plane/sand it flat to glue the outers to once it dries. I added one more strip to the bottom while I was at it.

I also laminated in 3 layers into the stern stem channel and will plane/sand it flat to glue the outers to once it dries. I added one more strip to the bottom while I was at it.

I'm wondering if you are planning on adding a brass stem strip, might be difficult with the edge you have on the stem. Difficult to tell from the pic, but I'm thinking your external stem might be riding a bit high. I usually follow the contour of the strips, rightly or wrongly...here's a pic of when I roughed it out on one of my Osprey builds.

Thanks for that Mem, yes they are currently too high. I just wanted a level starting point I can work down from. I'll be putting a strip along the hull to check curvature when I sand down to the finished product. No I won't be using brass stems. I'd like to go pretty fine on the ends with an extra layer of glass for durability. Darn responsibilities keeping me from working on it today.

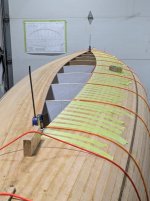

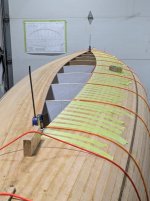

Well as the seasons change here I haven't had a lot of time for the boat. Just a little bit here and there. I got out for one last ride on the dual sport and got the house ready for winter. I've added to the stern laminations, they're bent, dried and ready for epoxy. I spent some time at it today and finished planking the hull. I decided to use a sliver of walnut for the whiskey strip since it was nicely centered. I over sanded one side and will have to glue in a shaving to hide it.

Well I made the long drive and picked up the aluminum gunnels and some more epoxy from Boatcraft. I took a couple of measurements off them and ordered some rivets and some back up washers.

I got the stern laminations on using every ratchet strap I have. I used wax paper to keep from ruining the straps. It really helped to alternate the ratchets to keep the stack from shifting to one side. I'm pretty happy with how they turned out.

While I'm saving the tumblehome section sanding for last I made a pass over the rest (except the stern) with some 80 grit Abranet on the long board. I'm pretty impressed with how long this stuff last. I did uncover some dents here and there. Hopefully a little water will help raise them.

I got the stern laminations on using every ratchet strap I have. I used wax paper to keep from ruining the straps. It really helped to alternate the ratchets to keep the stack from shifting to one side. I'm pretty happy with how they turned out.

While I'm saving the tumblehome section sanding for last I made a pass over the rest (except the stern) with some 80 grit Abranet on the long board. I'm pretty impressed with how long this stuff last. I did uncover some dents here and there. Hopefully a little water will help raise them.

I used aluminum gunnels on my composites. The Bell type. Great gunnels, but they are stiff, as they should be. This is not a complaint, but rather a tip to installation.

I had force the gunnels to follow the hull shape.

I found the best way, was to figure how wide my two thwarts needed to be, and where. I wanted them.

Beings mine was a Symmetrical hull ? I placed the thwarts equal distance from the center.

These served as the Fulcrum point to force the gunnels into shape, as I forced them to the stems ? I cut and fit grab handles, as anchor points for the Fulcrum.

This was needed to relieve any undo pressure on the stems, that would tend pull them apart.

Sorry I don't have a good pic to show.

I'm thinking you may need to do the same with your hull ?

I do have a pic, that shows.

composite gunnels

Jim

I had force the gunnels to follow the hull shape.

I found the best way, was to figure how wide my two thwarts needed to be, and where. I wanted them.

Beings mine was a Symmetrical hull ? I placed the thwarts equal distance from the center.

These served as the Fulcrum point to force the gunnels into shape, as I forced them to the stems ? I cut and fit grab handles, as anchor points for the Fulcrum.

This was needed to relieve any undo pressure on the stems, that would tend pull them apart.

Sorry I don't have a good pic to show.

I'm thinking you may need to do the same with your hull ?

I do have a pic, that shows.

composite gunnels

Jim

- Joined

- Aug 10, 2018

- Messages

- 2,170

- Reaction score

- 7,331

Is that aluminum gunwale a slip-on that covers inner & outer? Just drill thru & rivet in place? If so, I'll have to look into that. (If not, I''ll have to do some brain picking w/ a local fabricator)

Here's a better picture that shows the two together. I assume these are made by Clipper as they are what came on my Caribou S. These are available at a few shops in Western Canada. My Caribou has vinyl covers over them but I don't want the extra weight. I also bought the thwart material, end caps, seat hanger and seat from them. They slip over the hull and are riveted. The wide side goes to the inside and the thwarts are riveted up from the bottom.

I haven't mapped out thwart placement or seat placement yet. I'd love to hear some input though. I'm hoping they will flex into place without too much trouble. I thought I'd measure my Caribou and copy the placement from that. You think that's not a good idea being symmetrical vs Swede form?

I haven't mapped out thwart placement or seat placement yet. I'd love to hear some input though. I'm hoping they will flex into place without too much trouble. I thought I'd measure my Caribou and copy the placement from that. You think that's not a good idea being symmetrical vs Swede form?

Yeah, I mapped the thwart placement, for my Bell gunnels. The only way I could get them to bend, to follow the shape of the shear.

So how will you hang the seats ?

The Bell gunnels are a two piece gunnel, with a "L" shape inside, that fits into a groove, of the main gunnel.

They won't work with a stripper. They are made for the thin glass hull. You might make them work, by modify the "L"inner strip.

Those gunnels will definitely lighten the canoe. Should work fine !

Jim

So how will you hang the seats ?

The Bell gunnels are a two piece gunnel, with a "L" shape inside, that fits into a groove, of the main gunnel.

They won't work with a stripper. They are made for the thin glass hull. You might make them work, by modify the "L"inner strip.

Those gunnels will definitely lighten the canoe. Should work fine !

Jim

The Clipper construction seems quite robust despite being lightweight. I thought the seat hangers were powder coated aluminum but it turns out they're fiberglass. I ordered the thwart tubing, seat hanger, seat and end caps from Western Canoe and Kayak. The hanger comes as a single piece and I'll use a zip cut to give it 1" of rake and get the height right.

No progress on the boat to report. I've been sick on the couch since the sanding day.

No progress on the boat to report. I've been sick on the couch since the sanding day.

I roughly shaved down the stern stem with the RO sander with some 60 grit. After doing so I could see I was a hair thin on making the curve look right. I epoxied on a few more laminations the shaved it down and shaped it some as I finished rough sanding the hull. I've still left it proud for final shaping. I will be leaving it a little high though Memaquay. From the end the stem's certainly not as uniform as I would have hoped.

When I sanded the keel line I was careful to approach it from one side then the other. Try not erase any center line by sanding it away.

I have no gas after being sick. Using the long board I tire out quite quickly. I pulled out all the picture hanging nails on the tumblehome section and used some 80 grit Abranet to level the walnut accent strip and rough sand the yellow cedar. I managed to get one side done over the course of the day before quitting early. I'm not minding the yellow cedar as much now.

When I sanded the keel line I was careful to approach it from one side then the other. Try not erase any center line by sanding it away.

I have no gas after being sick. Using the long board I tire out quite quickly. I pulled out all the picture hanging nails on the tumblehome section and used some 80 grit Abranet to level the walnut accent strip and rough sand the yellow cedar. I managed to get one side done over the course of the day before quitting early. I'm not minding the yellow cedar as much now.

Last edited:

I'm not sure if you are familiar with www.greenval.com

Martin Step is the fella that has been handling all of John Winter's designs for many years. He is out of business now, Noah's is handling the plans, but he has left the website up with a lot of valuable info. Over the past 30 years, Martin has assisted me with building almost every single canoe John designed, lol. I never built the Kite, but I have built several Ospreys, which is essentially the Kite without the flat top. He has a section on the site called "Builder's Notes". I have copied the section pertaining to shaping the external stems for your perusal.

Fairing the Outside Stem:

The outer stems need to be planed down flush with the outside of the hull, with a nice radius along the centerline. If you used screws during gluing, remove them before planing. The radius should never be much less than 3/8", and of course with the tapered stems, it would reach a 3/4" radius at the gunwales (1 1/2" diameter).

Please note that along the keel line, you will have to plane away at least 1/2" or two layers of the original lamination's thickness. I am amazed at the number of people who thought that the outer stem was intended to stick out, but that is not the case. You start out with three layers of wood in the outer stem because you need all three layers on the vertical part, and because it won't hold a bend long enough to fit it without the extra wood along the bottom. But, when the boat is finished, this extra has to be gone. As a guide to how they should look, I've added three more photos on my website this evening just for you. Look at the Builders Corner on the Green Valley Boat Works web site.

Martin Step is the fella that has been handling all of John Winter's designs for many years. He is out of business now, Noah's is handling the plans, but he has left the website up with a lot of valuable info. Over the past 30 years, Martin has assisted me with building almost every single canoe John designed, lol. I never built the Kite, but I have built several Ospreys, which is essentially the Kite without the flat top. He has a section on the site called "Builder's Notes". I have copied the section pertaining to shaping the external stems for your perusal.

Fairing the Outside Stem:

The outer stems need to be planed down flush with the outside of the hull, with a nice radius along the centerline. If you used screws during gluing, remove them before planing. The radius should never be much less than 3/8", and of course with the tapered stems, it would reach a 3/4" radius at the gunwales (1 1/2" diameter).

Please note that along the keel line, you will have to plane away at least 1/2" or two layers of the original lamination's thickness. I am amazed at the number of people who thought that the outer stem was intended to stick out, but that is not the case. You start out with three layers of wood in the outer stem because you need all three layers on the vertical part, and because it won't hold a bend long enough to fit it without the extra wood along the bottom. But, when the boat is finished, this extra has to be gone. As a guide to how they should look, I've added three more photos on my website this evening just for you. Look at the Builders Corner on the Green Valley Boat Works web site.

I spent some more time sanding on the tumblehome section with the longboard. I offset the sandpaper a little to not chew into the piece below it. I also used the longboard to round over the walnut so the glass will lay better. I then used the random orbital and made 2 passes with 180 grit. I have the stems mostly shaped now and will just do some touch ups by hand for the final bit until they look right.

Looks really good, the walnut is great!

Similar threads

- Replies

- 3

- Views

- 348

- Replies

- 31

- Views

- 2K