Jim, I'm sure tech will be here soon to 3D print the hull you want but what fun would that be?

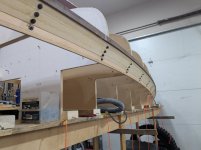

So I finally got the hang of the Robo Bevel. I was doing a couple of things wrong. First I was tipping it too far over on the forms. Second I was starting at the center and working out to the ends. You really need to go both directions. If you just go one direction it leaves a bit behind and I was doing a poor job shaving it with the razor knife. Now I start at one end and slowly work my way to the other in a single pass. Then I flip the plane in the Robo Bevel and go the other way. After 4 passes it's done. I still go along and shave any inconsistencies. The bit at the stems always needs cleaning up. I see as I get higher the hull is slightly moving away from the form so I added another screw for the lashings to go around. Pulls the wood in and then down.

So my incredibly slow method goes like this:

-4 passes plus clean up with of fine details, then check for irregularities etc.

-Test fit new strip after giving the inside should a quick pass with sand paper.

-Glue/lash the first two feet then hot glue lash the end

-Work my way down gluing about 4' at a time lashing and taping as I go. I use 3 pieces of tape between stations then suck it down further with 3 more. Pretty much a piece of tape every 2" by the time I'm done. Doing this hoping for a tight fit and less weight due to less epoxy.

-I pinch the seam into alignment as I go. When I get to the end I hot glue tack that end as well and go work on the other side. My glue dries in 20 minutes so it's ready by the time I finish the other side.

As for tape I made the mistake of buying some Painter's Mate instead of my usual 3M Scotch 1" painters tape. The Painter's Mate doesn't adhere so well and keeps popping loose. With the 3M Scotch I only have to use a few inches and it sticks well. As I used up my old stock I see they've made it thinner but it seems stronger and sticks better so that's good.

As for the time I must admit that I'm having fun as I go. I normally build in the winter with the garage door closed. With nice weather and the garage open I get lots of people stopping for a look and enjoying the progress. So even with getting the hang of the tool It's still taking me an hour by the time I remove the cords and tape to start the next strip. Definitely not worth it to not use staples.