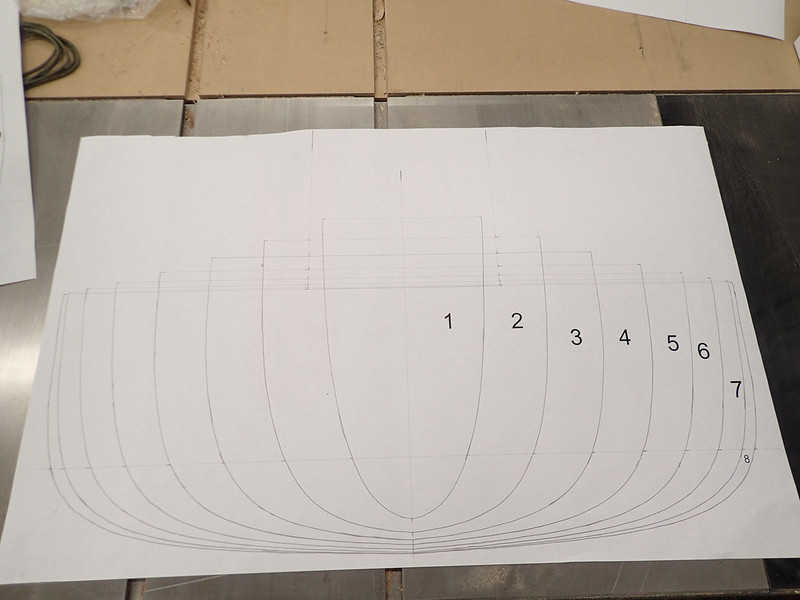

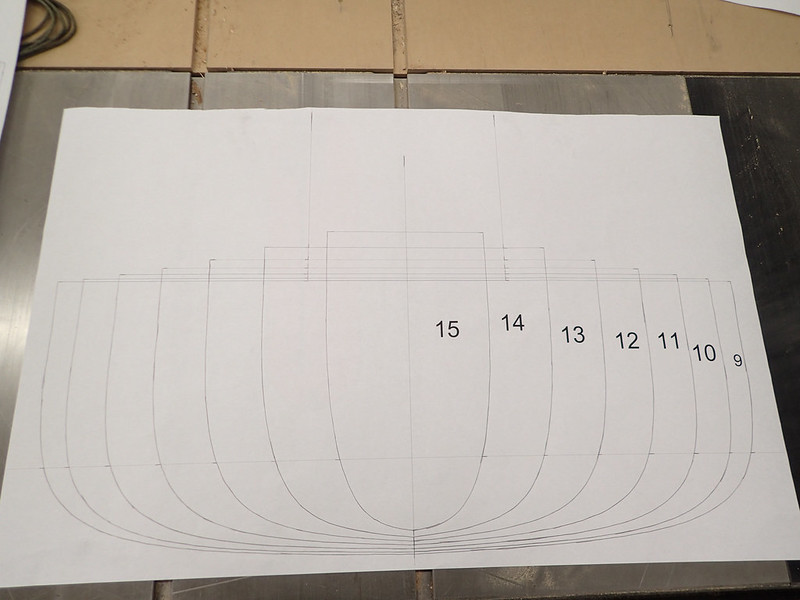

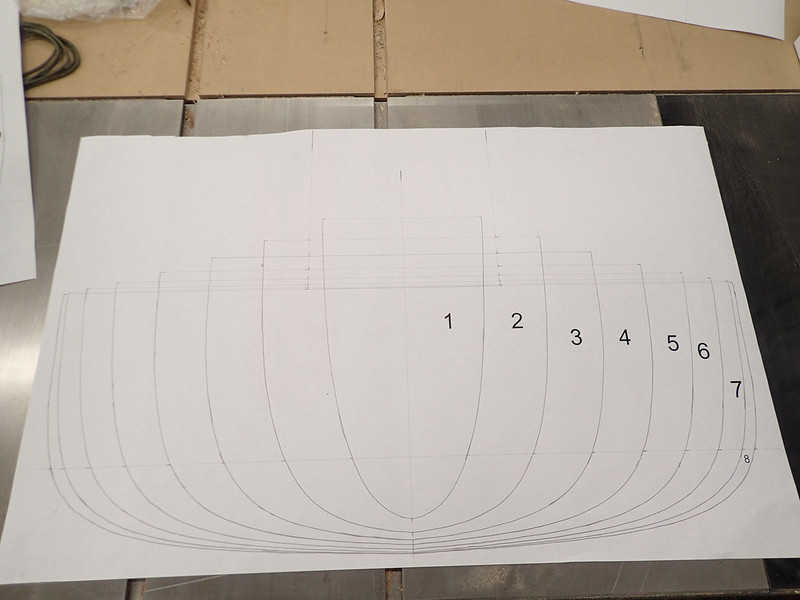

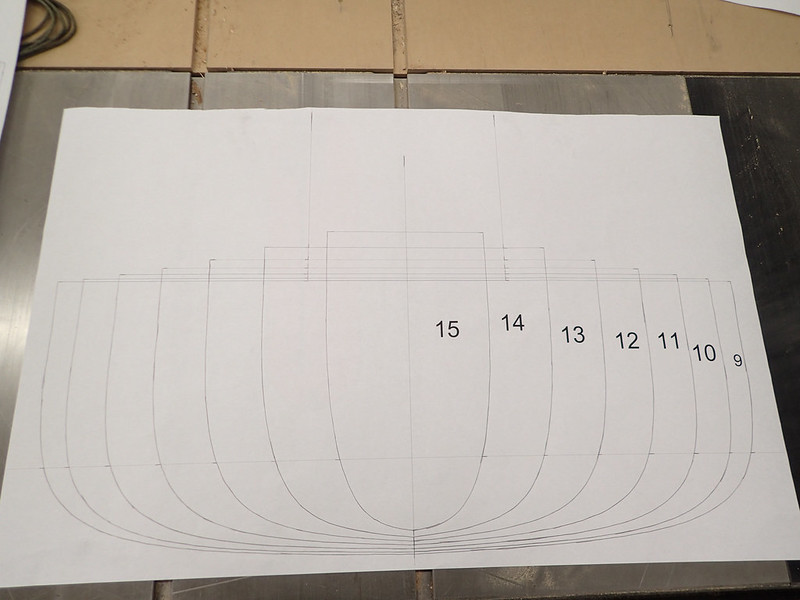

Another tandem for the nature center to raffle at their spring fundraiser. Should be a nice boat but nothing unique at 16.5' by 35" wide. Roughly 19, 13, 16 if I remember correctly for shear heights. I plan to use this stripper as a mold for a carbon/kevlar copy for myself before it comes off the strongback.

20151111_006 by Alan, on Flickr

20151111_006 by Alan, on Flickr

20151111_007 by Alan, on Flickr

20151111_007 by Alan, on Flickr

Forms went up quick tonight; not that it really matters because the cedar that showed up today is junk as far as strips go; so I need to hold my horses and wait for more. The stem forms aren't attached yet and still need to be tapered. So far everything looks pretty fair after holding strips in place along the forms.

20151111_003 by Alan, on Flickr

20151111_003 by Alan, on Flickr

The shear line is 1 1/2" lower than the edges of the forms show. The actual shear line is the black pencil marks.

Hopefully I'll come up with a catchier name but for now the working title for the boat will be 'GP' for General Purpose.

Maybe since I'm waiting I can finish cleaning up the shop. As soon as it got to the point it was clean enough for another build I sorta lost motivation to go further.

Alan

20151111_006 by Alan, on Flickr

20151111_006 by Alan, on Flickr 20151111_007 by Alan, on Flickr

20151111_007 by Alan, on FlickrForms went up quick tonight; not that it really matters because the cedar that showed up today is junk as far as strips go; so I need to hold my horses and wait for more. The stem forms aren't attached yet and still need to be tapered. So far everything looks pretty fair after holding strips in place along the forms.

20151111_003 by Alan, on Flickr

20151111_003 by Alan, on FlickrThe shear line is 1 1/2" lower than the edges of the forms show. The actual shear line is the black pencil marks.

Hopefully I'll come up with a catchier name but for now the working title for the boat will be 'GP' for General Purpose.

Maybe since I'm waiting I can finish cleaning up the shop. As soon as it got to the point it was clean enough for another build I sorta lost motivation to go further.

Alan