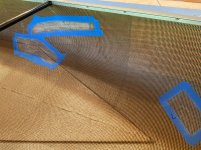

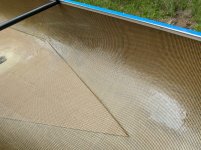

Here's a pic which shows level of lack of gloss, degree of pebble, and toughness of aftermarket (manufacturer provided, user applied) vinylester. As harsh a scratch as the worst pre-repair (other than primary complaint), happened as I shoved off.

When I added my weight the boat of course settled, and I kinda felt a bit of a resistance which tightened my neck muscles, tho only because of the fresh repair. I didn't actually think anything was happening. I'm not sure I noticed the big one happen as I pushed of from bank or not.

It did not take much to big-digger the new coat.

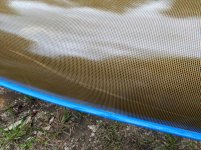

The finish is not full flat. Maybe a matte. In the shadows it looks about normal, in the shines you can see the dull. And the orange peel.

Its not horrid, but it's not new.

I'm happy enough with how it came out. Only because I have revised my opinion of how perfect this boat should look.

And I think I prefer fishing from this round bottomed boat over the flat Royalex. I had a little over three inches of freeboard, plenty for a 17ac TN reservoir protected by steep TN hills. I prefer the responsiveness of this canoe: its liveliness keeps me paying full attention to my whole body and the world around as I cast, retrieve, fight and net a fish (I hunt for crappie with an UltraLight rig: big bass tend to ignore my puny offerings). It's faster, straighter, and more precise a paddler. It is a lot louder to stow said paddle. But a lot lighter to pack the 250yard trail to the pond. I think I'll redefine that touchiness to paddle impact as extra finesse required for the hunt, as I delicately sneak up on the schools.

Thanks Erk, for prodding me to recognize the depth of my desire to get this boat in water sooner than the river rises to an acceptable level (this winter). You took my fishing involvement to new heights.