Finally got around to making a composite copy of my short Merlin. I just used multiple coats of carnuaba wax for mold release, and it was a bear to remove, but I got it done! I used 2 layers of 5 oz kevlar/carbon hybrid fabric first, covered by 2 layers of 4 oz e glass I had lying around. It feels really floppy, so I'm going to have to add more cloth I think. Would 2 more layers of 4 oz e glass be stiffer than one layer of say something around 8 oz, or does it make any difference? I'm planning on trying to do some wood ribs on the inside to keep the bottom stiff, kind of like a canvas canoe has, but not as many ribs of course. Or maybe Jim Dodds cedar strip partial bottom. Thanks for all the inspiration I got from you guys for this project!

-

Happy 3rd Moon Landing, Apollo 14 (1971)! 🚀👨🚀🌕

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Composite Merlin

- Thread starter Merlin

- Start date

Cool !

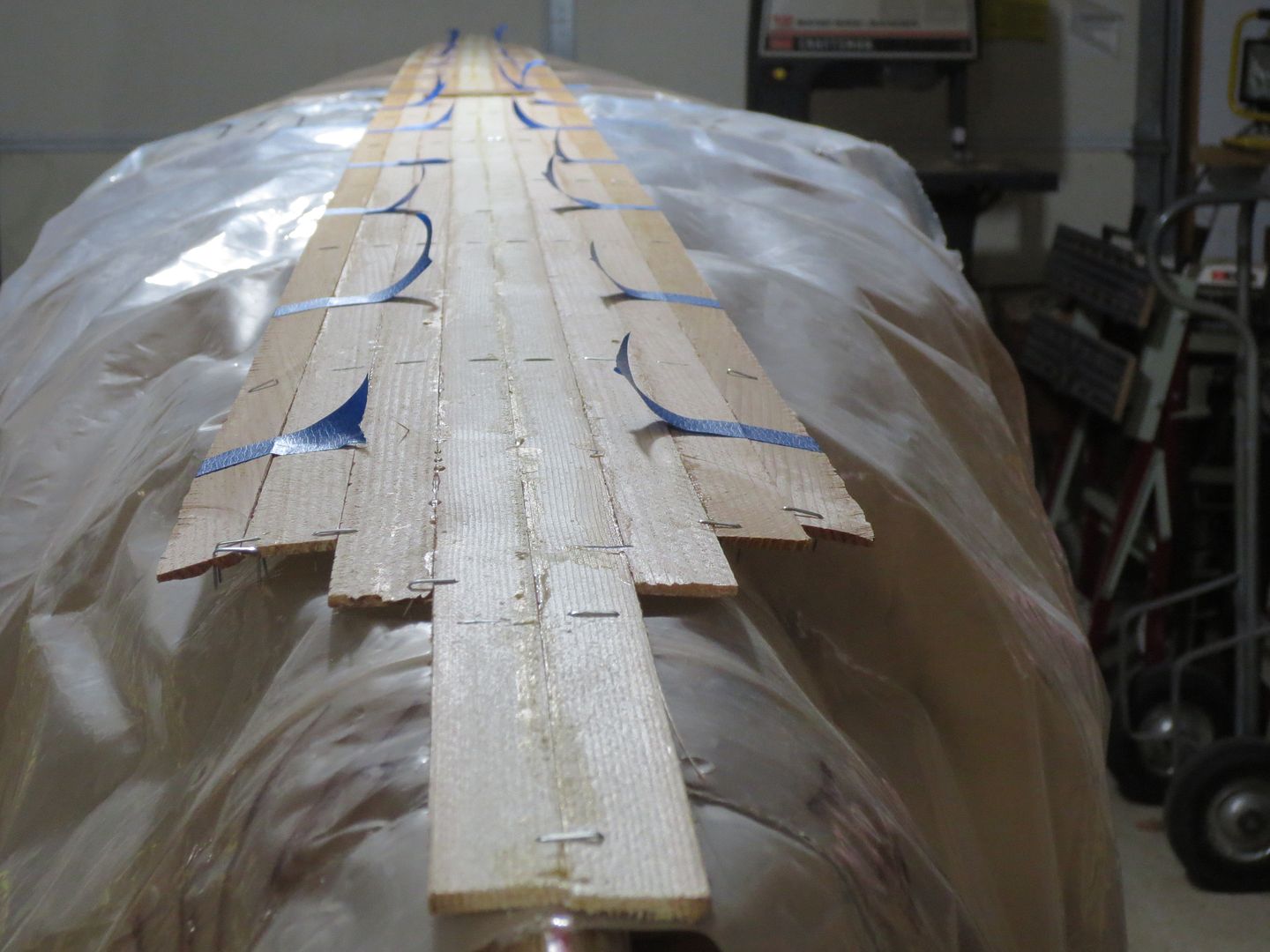

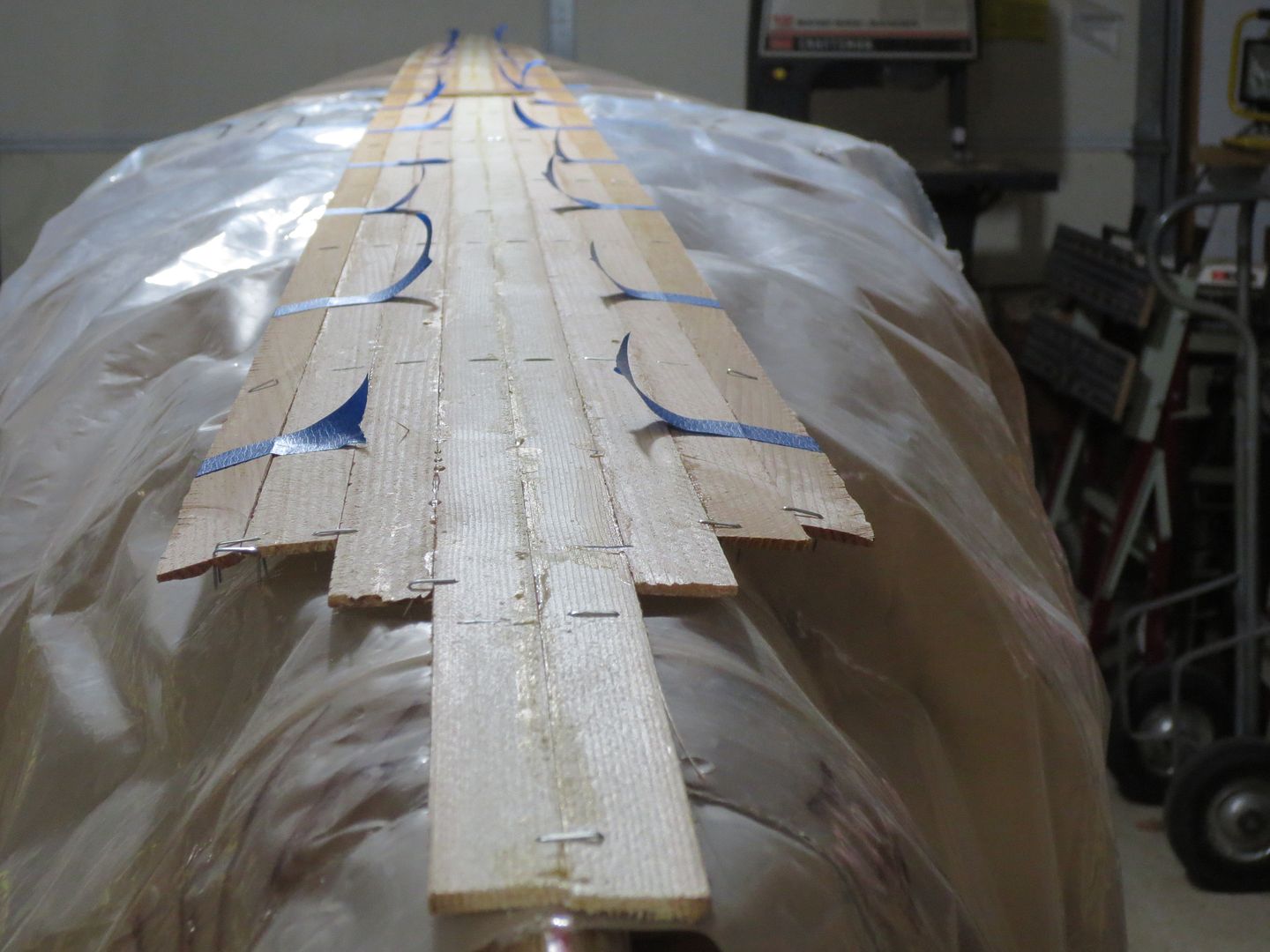

I'd recommend an insert for sure. I set up my forms and stripped up a cedar insert,1/8" thick. Pretty easy to do. No bead and cove, just edge glued the strips. Started at the center and worked out.

A layer of cloth was added on top of the insert to seal, and stiffen.

Stripperguy used a foam insert, and that might be a good route.

I am happy with the stiffness my cedar insert provided, as well as the weight.

Epoxied the insert to the hull with filled epoxy. I used sand to weigh the insert against the hull. BESURE to support the hull if you use my method !

I used about 150# of sand, spread out on plastic to do this, but if you can vacumm bag, that would work best in my opinion.

Stiffen the sidewalls ! I used extra layers of E-glass, in the center area. I wished I had used more, as I'm still not quite happy the sidewall stiffness.

Keep us posted ! You will love this hull when completed ! Especially when you portage !

Jim

I'd recommend an insert for sure. I set up my forms and stripped up a cedar insert,1/8" thick. Pretty easy to do. No bead and cove, just edge glued the strips. Started at the center and worked out.

A layer of cloth was added on top of the insert to seal, and stiffen.

Stripperguy used a foam insert, and that might be a good route.

I am happy with the stiffness my cedar insert provided, as well as the weight.

Epoxied the insert to the hull with filled epoxy. I used sand to weigh the insert against the hull. BESURE to support the hull if you use my method !

I used about 150# of sand, spread out on plastic to do this, but if you can vacumm bag, that would work best in my opinion.

Stiffen the sidewalls ! I used extra layers of E-glass, in the center area. I wished I had used more, as I'm still not quite happy the sidewall stiffness.

Keep us posted ! You will love this hull when completed ! Especially when you portage !

Jim

Congrats on getting it done AND off your other boat!! I don't know about you, but for me, that step was a real butt puckering moment...

It could take up to a week before your resin gets to its full hardness, until then you shouldn't make any rash decisions about the stiffness. Your hull will also firm up a bit when you close up the stems.

How much does your shell weigh right now? I was really excited when my bare shell came off of my plug weighing only 16 lbs (or so), then really bummed at my final weight of 29 lbs.

But, back to your boat. The most cost effective balance of added stiffness and lowest weight will come from some sort of stiffening substrate and a layer or two of glass over that. Pretty much the same construction as most strip builds. Jim used more cedar strips. I used 1/8" thick H80 Divinycell. IIIRC, the Divinycell was 5 lbs/ft^3. Cedar is about 22 lbs/ft^3.

I epoxied it in place and then added a layer of 5 oz carbon over the top. I should have used a layer or two or 4 or 6 oz E-glass.

Below is a photo of my partially finished Carbon Copy Kite, no gunnels, no decks, no bulkheads and no thwarts. I weigh 150 lbs and the cradle supports are 8 ft apart. I could detect NO deflections as I stood in the hull!! I'd say that's testament enough for the powers of a little extra thickness. I remember Alan did something like 9 or 13 layers and still wasn't fully satisfied with his hull stiffness.

My Kite has a very pronounced knuckle. That knuckle provides plenty of lateral stiffness in my hull. If you hull is more conventionally shaped (like Jim's) you may need some addition stiffening in the sides as well. Also depends on how you make your gunnels.

My gunnels are carbon fiber and glass over foam. I was disappointed at how much resin the carbon required to wet out. That led to a substantial weight gain. When I do it again, I will use only glass over the foam.

Anyway, I've rambled enough. Looking forward to seeing the rest of yor build!

View attachment -7SqLZN1d9Ty9OeVjtiNLwGfJ2pZCq6eMsrst3Jufw5xdKM8nk0tXLyXbnGoWD8aDYi_mnHfQx_CxI8rzPpabWQ5NXgj_DcquRxc

It could take up to a week before your resin gets to its full hardness, until then you shouldn't make any rash decisions about the stiffness. Your hull will also firm up a bit when you close up the stems.

How much does your shell weigh right now? I was really excited when my bare shell came off of my plug weighing only 16 lbs (or so), then really bummed at my final weight of 29 lbs.

But, back to your boat. The most cost effective balance of added stiffness and lowest weight will come from some sort of stiffening substrate and a layer or two of glass over that. Pretty much the same construction as most strip builds. Jim used more cedar strips. I used 1/8" thick H80 Divinycell. IIIRC, the Divinycell was 5 lbs/ft^3. Cedar is about 22 lbs/ft^3.

I epoxied it in place and then added a layer of 5 oz carbon over the top. I should have used a layer or two or 4 or 6 oz E-glass.

Below is a photo of my partially finished Carbon Copy Kite, no gunnels, no decks, no bulkheads and no thwarts. I weigh 150 lbs and the cradle supports are 8 ft apart. I could detect NO deflections as I stood in the hull!! I'd say that's testament enough for the powers of a little extra thickness. I remember Alan did something like 9 or 13 layers and still wasn't fully satisfied with his hull stiffness.

My Kite has a very pronounced knuckle. That knuckle provides plenty of lateral stiffness in my hull. If you hull is more conventionally shaped (like Jim's) you may need some addition stiffening in the sides as well. Also depends on how you make your gunnels.

My gunnels are carbon fiber and glass over foam. I was disappointed at how much resin the carbon required to wet out. That led to a substantial weight gain. When I do it again, I will use only glass over the foam.

Anyway, I've rambled enough. Looking forward to seeing the rest of yor build!

View attachment -7SqLZN1d9Ty9OeVjtiNLwGfJ2pZCq6eMsrst3Jufw5xdKM8nk0tXLyXbnGoWD8aDYi_mnHfQx_CxI8rzPpabWQ5NXgj_DcquRxc

Merlin

Another thought , it will also matter how you make your seat ! Hanging from the gunnel, or on a pedestal off the bottom. I believe hanging the seat from the gunnels, puts more stress on the hull, than a pedestal.

Jim

Another thought , it will also matter how you make your seat ! Hanging from the gunnel, or on a pedestal off the bottom. I believe hanging the seat from the gunnels, puts more stress on the hull, than a pedestal.

Jim

Cool! I'll be following along on the rest of your build. Thanks for sharing,

Jason

Jason

Congrats on getting it done AND off your other boat!! I don't know about you, but for me, that step was a real butt puckering moment...

It could take up to a week before your resin gets to its full hardness, until then you shouldn't make any rash decisions about the stiffness. Your hull will also firm up a bit when you close up the stems.

How much does your shell weigh right now? I was really excited when my bare shell came off of my plug weighing only 16 lbs (or so), then really bummed at my final weight of 29 lbs.

But, back to your boat. The most cost effective balance of added stiffness and lowest weight will come from some sort of stiffening substrate and a layer or two of glass over that. Pretty much the same construction as most strip builds. Jim used more cedar strips. I used 1/8" thick H80 Divinycell. IIIRC, the Divinycell was 5 lbs/ft^3. Cedar is about 22 lbs/ft^3.

I epoxied it in place and then added a layer of 5 oz carbon over the top. I should have used a layer or two or 4 or 6 oz E-glass.

Below is a photo of my partially finished Carbon Copy Kite, no gunnels, no decks, no bulkheads and no thwarts. I weigh 150 lbs and the cradle supports are 8 ft apart. I could detect NO deflections as I stood in the hull!! I'd say that's testament enough for the powers of a little extra thickness. I remember Alan did something like 9 or 13 layers and still wasn't fully satisfied with his hull stiffness.

My Kite has a very pronounced knuckle. That knuckle provides plenty of lateral stiffness in my hull. If you hull is more conventionally shaped (like Jim's) you may need some addition stiffening in the sides as well. Also depends on how you make your gunnels.

My gunnels are carbon fiber and glass over foam. I was disappointed at how much resin the carbon required to wet out. That led to a substantial weight gain. When I do it again, I will use only glass over the foam.

Anyway, I've rambled enough. Looking forward to seeing the rest of yor build!

I don't have a way to weigh it, but it felt super light!

No Title

Here's an update on my progress. Took it out for the first time the other day. Handled great, but I still need to add something to stiffen up the bottom. It was still a bit floppy. Sure is a joy to load and carry!

Here's an update on my progress. Took it out for the first time the other day. Handled great, but I still need to add something to stiffen up the bottom. It was still a bit floppy. Sure is a joy to load and carry!

Attachments

My first composite, Oil cans terrible. It's stable, and reasonably fast. It still baffles me ! I used Pink Foam, and a layer of 6 oz E-glass. Foam pretty much delaminated, and did nothing but add a very small amount of flotation.

If you can afford, some proper foam, and cover with S-glass, cover the football with foam, and extra layers of S-glass up the sides, around where the seat is. That would be good,

Or as I did, and will do again, set up your forms, and make a cedar insert, with 1/8" + strips. Edge glue, cut to shape, insert, and apply a layer of glass.

Whether you use foam, or a cedar core, bevel the edges, so the cloth lays smoothly.

I paddled a BK Merlin yesterday ! That had the stems rockered. A very sweet canoe !

Jim

If you can afford, some proper foam, and cover with S-glass, cover the football with foam, and extra layers of S-glass up the sides, around where the seat is. That would be good,

Or as I did, and will do again, set up your forms, and make a cedar insert, with 1/8" + strips. Edge glue, cut to shape, insert, and apply a layer of glass.

Whether you use foam, or a cedar core, bevel the edges, so the cloth lays smoothly.

I paddled a BK Merlin yesterday ! That had the stems rockered. A very sweet canoe !

Jim

Last edited:

Finally got around to making a composite copy of my short Merlin. I just used multiple coats of carnuaba wax for mold release, and it was a bear to remove, !

Where did you have the most trouble getting the hull to release ? On the bottom, or the sides ?

Thanks !

Jim

Where did you have the most trouble getting the hull to release ? On the bottom, or the sides ?

Thanks !

Jim

It was mostly on the bottom that I had problems. I ended up having to work some long strips of wood in from the ends to kind of pry it loose a little bit at a time.

Thanks !

On my next composite, I plan to use Shrink Wrap on the bottom, and mold release on the sides. Others have stated, that the bottom was the hardest to break loose.

The Shrink wrap has always released the hull with no effort, but it was difficult to keep the cloth tight to the hull in the tumblehome area !

Thanks for your observation !

Jim !

On my next composite, I plan to use Shrink Wrap on the bottom, and mold release on the sides. Others have stated, that the bottom was the hardest to break loose.

The Shrink wrap has always released the hull with no effort, but it was difficult to keep the cloth tight to the hull in the tumblehome area !

Thanks for your observation !

Jim !

Actually, the sides of my Kite, with that crazy knuckle, was the hardest to break free for me. But I did also use a couple of long tapered strips to reach far in and help the release.

I'm still saying that a little foam (yes, the good stuff) and some glass will stiffen that hull amazingly well.

And where's Jim? Nothing against your stripped stiffeners, but I just realized why I don't care for them. I think it's that the strips are parallel to the keel. Strictly a personal thing for me, but if those strips followed some buttress line, like all of your stripped hulls, I think that would make for an aesthetic overload!!

Anyway, that almost Merlin looks great, Merlin. Is it painted? I can't quite tell, maybe red?

I'm still saying that a little foam (yes, the good stuff) and some glass will stiffen that hull amazingly well.

And where's Jim? Nothing against your stripped stiffeners, but I just realized why I don't care for them. I think it's that the strips are parallel to the keel. Strictly a personal thing for me, but if those strips followed some buttress line, like all of your stripped hulls, I think that would make for an aesthetic overload!!

Anyway, that almost Merlin looks great, Merlin. Is it painted? I can't quite tell, maybe red?

And where's Jim? Nothing against your stripped stiffeners, but I just realized why I don't care for them. I think it's that the strips are parallel to the keel. Strictly a personal thing for me, but if those strips followed some buttress line, like all of your stripped hulls, I think that would make for an aesthetic overload!!

I'm here .

I would have LOVED to use foam, the Good stuff ! But couldn't find a source locally ! It would have been a ton easier, and lighter for sure ! Just had to make do, with what I had !

As for the design, I wanted a Black Moon in Vader, opposite of the Full Moon in Nokomis. Parallel strips were easier !

Stripperguy ! I'm surprised you had trouble working the hull off the knuckle. With the ends split ? Was it because of adhesion, or just the contour of the hull ?

Jim

I'm here .

I would have LOVED to use foam, the Good stuff ! But couldn't find a source locally ! It would have been a ton easier, and lighter for sure ! Just had to make do, with what I had !

As for the design, I wanted a Black Moon in Vader, opposite of the Full Moon in Nokomis. Parallel strips were easier !

Stripperguy ! I'm surprised you had trouble working the hull off the knuckle. With the ends split ? Was it because of adhesion, or just the contour of the hull ?

Jim

Yeah, the stems were open. Adhesion was high, and the knuckle prevented me from working a parting tool (sharpened strip of cedar) vertically from sheer towards the waterline. I could only work the parting tool in horizontally from the open stems towards midships.

Add to that my weakened grip strength from having carpal tunnel surgery on both hands...and, well, let's just say I was mighty relieved to hear that final "pop".

And Merlin, I vote for red!

I used a rubber mallet and banged around all over the hull to help break the bond. This worked best on the bottom and other areas with a lot of flex. You could hear it snap as a section would break loose. I also used some of other methods already mentioned here.

Alan

Alan

Update. I did something a little different for stiffening the bottom and added some steambent 1/4 inch thick walnut partial ribs. Covered with 2 layers of 6 oz fiberglass tape. Also added waterproof dry storage hatches to each end.

Attachments

Looks great, and very functional! Is it just me or does that thwart have a nice curve to it like those Souris Rivers?

It' actually just a simple straight thwart, but it does lol curved in the photo.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 46

- Views

- 5K

- Replies

- 43

- Views

- 9K