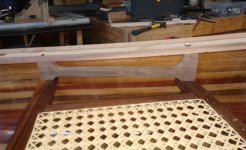

Installing the seats in my canoe, and looking for advice. This canoe is Gil Gilpatricks Wabnaki design. I've made the traditional flat canoe seats out of black walnut, 7/8 thick by 1 3/4 frame, I think this is sturdy enough for my 215# rear end. I weaved them with plastic artificial cane. I've got them at a height of 9+ inches underneath. According to Canoe Craft by Ted Moores 9.5 to 10.5 is a good height for feet placement for kneeling. I don't expect to kneeling in this, but ya never know and my feet are a little large 13EW. Yes Bigfoot exists in East Tennessee. The seats look to high to me, but that may be due to the canoe design. I'm going to have recut the back seat hangers, which they are roughed in anyhow.

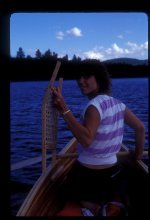

Am I ok with this seat height as far as comfort, and stability is concerned? I wanted to leave the seats level so when I go solo I can sit in the bow seat facing the stern.

Just lots on my mind concerning comfort, stability and if I'm going to brake my seats or gunnels or who knows.

Any advice on any of this is greatly welcome and appreciated.

Am I ok with this seat height as far as comfort, and stability is concerned? I wanted to leave the seats level so when I go solo I can sit in the bow seat facing the stern.

Just lots on my mind concerning comfort, stability and if I'm going to brake my seats or gunnels or who knows.

Any advice on any of this is greatly welcome and appreciated.