Has anyone here built their own canoe paddle?

I don't have the funds at the moment to build a canoe but a paddle on the other hand....

I don't have the funds at the moment to build a canoe but a paddle on the other hand....

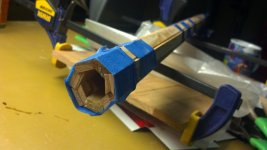

Thanks mem. I was thinking about a hollow shaft with birds mouth joinery. Any thoughts?

Never built a paddle, but I've reworked a couple. There's a maker in Minnesota that makes paddles by hand and when I got mine home I found all kinds of flaws. I ended up reshaping the grip, the shaft, and parts of the blade. Not much fun, but now I have a real "favorite."

Thanks mem. I was thinking about a hollow shaft with birds mouth joinery. Any thoughts?

I've only built a couple of paddles and always assumed that a multi-ply shaft is the strongest. But now I'm wondering. Maybe we can get stripperguy to make up some paddle shafts and do some strength testing for us in all the spare time he has between his day job, building apartments, re-building motorcycles, building canoes, property management, bc ski trips, etc., etc.

This web site uses the birds mouth method for the shaft. http://ngc704.home.comcast.net/~ngc704/paddles/ Was thinking about this myself. Wife wishes a stand up/polling paddel for when she stands up in the Mad River Explorer.

Just looking at a cross-section of birds mouth joinery, I'd say it could be strong, provided it's wrapped in fiberglass. Otherwise it seems like it could easily crack if levered against a gunwale.

Sawyer makes a paddle called the Kai. It's a 10* bent shaft with a bamboo blade and a hollow carbon fiber shaft with a bamboo wrap. Nice, light paddle with a small blade, but the joint at the throat can come apart (I fixed mine with duct tape in the field, then epoxy at home).