I got from a friend an 18' 6" Bell Mystic for free last year. This boat has a bad juju history. He bought it brand new, didn't tell his wife, and trailered down to Florida and on a dirt road going to the putin he watched in the side view mirror it bounce off the trailer and do a nose dive into the dirt. Bent the hell out of the gunwales but was able to fix them enough to paddle. Months later he and I put new gunwales, aluminum, which took the better part of a day with a lot of swearing and pounding with rubber mallets to fit but got it done.

A couple of years go by and he moves, again, and storing the hull outside during a storm a piece of plexiglass from the cupula went sailing out from its frame, slide down the metal barn roof and at about 100 mph punctured the side of the canoe. Bad juju!

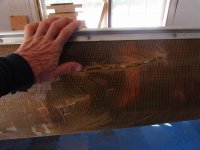

So another friend says he wants it, hell I don't, but will fix it for him. This is kevlar and although I have worked on many a boat kevlar is not one of the materials I've done work on. I'm posting some pictures in hopes that I can get the wisdom of the canoe builders/fixer uppers on how to go about this. With FG I just cut out a slot where the puncture is but with Kevlar I think it will fuzz up pretty good from what I've read and asked about in the past. I am open to suggestions if any cares to jump in. I can measure the length of the puncture later but it is pretty long. In my minds eye the biggest problem is that the ends of the break are off set and that is where I am coming up short. The actual patch is easy enough but it's getting those frayed end together for a clean match up.

Many thanks for any suggestions/thoughts/come up to my shed and fix it while I look is welcome.

dougd

For some reason not all of the photo's copied over, something about being too big. Sorry, hope these give an idea of what I'm dealing with.

A couple of years go by and he moves, again, and storing the hull outside during a storm a piece of plexiglass from the cupula went sailing out from its frame, slide down the metal barn roof and at about 100 mph punctured the side of the canoe. Bad juju!

So another friend says he wants it, hell I don't, but will fix it for him. This is kevlar and although I have worked on many a boat kevlar is not one of the materials I've done work on. I'm posting some pictures in hopes that I can get the wisdom of the canoe builders/fixer uppers on how to go about this. With FG I just cut out a slot where the puncture is but with Kevlar I think it will fuzz up pretty good from what I've read and asked about in the past. I am open to suggestions if any cares to jump in. I can measure the length of the puncture later but it is pretty long. In my minds eye the biggest problem is that the ends of the break are off set and that is where I am coming up short. The actual patch is easy enough but it's getting those frayed end together for a clean match up.

Many thanks for any suggestions/thoughts/come up to my shed and fix it while I look is welcome.

dougd

For some reason not all of the photo's copied over, something about being too big. Sorry, hope these give an idea of what I'm dealing with.