I bought this canoe for 50 dollars (and a 400 mile round trip drive) off Craigslist. It is a 1985 DY Special, I believe in superlight kevlar (based on the weight after I got all the wood planking off last night). I got it from the original owner who, after years of using it in the BWCA and various Montana lakes, ended up taking it down the middle Yaak River with a lady friend on board. I've floated the middle Yaak (below town, above the falls) in a packraft, and it isn't especially rocky nor especially twisty, but I can imagine that a nearly 17 foot canoe with no rocker would on that stretch be hard work. The gentleman intimated that the influence of his companion led to unwise choices, and much boat damage. Long story short, his repairs amounted to 3/4" redwood planking, inside and out, glued to the hull, screwed through the hull to each other, tapered at the ends and edges, edged with spray foam or gorilla glue, and then glassed over with what appears to have been 4-6 oz glass and vast amounts of auto epoxy. He completed this repair and then put it away in his barn, where it stayed, lent out once, for the past 15 years. That one use was cousins crossing the Missouri just above Fort Peck during hunting season, and my assumption is that it was they who (as the gentleman put it) sat on the middle of the hull when it was upside down, adding some substantial but not full thickness cracks to the widest section of the tumblehome

I did take it for a paddle on the drive home, and aside from one little 2 tsp/minute crack near the seat, the thing floated no problem. Paddling characteristics were a little peculiar.

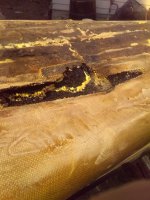

Getting all the planking and glass off wasn't nearly as bad as it could have been, due to the poor epoxy and dodgy glass work. The bow end wood was extensively rotted inside, as the glass job was just enough to let a bit of water in, then keep it there. After ~4 hours of cutting, prying, sanding, and a wee bit of swearing, the hull is almost back to the original state, with the addition of a bunch of cracks, 3 dozen screw holes, and a section towards the stern (where I assume his lady friend sat that fateful day) with water intrusion under the outer layers and plenty of puffy/crunchy kevlar fabric.

Unfortunately, being sandwiched between those wood layers for so long has crunched up the keel line of the DY Special, with 2/3s of the boat being 1 to 1.5 inches oilcanned below where it ought to be. I have a few repair questions I was hoping for help with, the first being how to best restore the hull line.

My thought is to make a mold (in essence) out of a 16 foot 2x4 or the like, with an angle that would mimick the gentle angle the boat held through the keel originally. Bracing this off the thwarts ought to hold the original shape while repairs cure and then hold that shape for the duration of the restoration. My question is how much fabric and/or epoxy will be adequate to establish this restored shape, and whether the inside or outside of the hull is the better place to start.

I anticipate using this in the MR 340 this coming year, and the TWS perhaps the year after that. Mostly, it will go on local lakes for fitness, and down flat but twisty central Montana rivers (Musselshell, Missouri, Milk, Marias) where the hull speed will be an asset. I would like the add enough layers of the right fabric to the outside to be able to run into the occasional log and rock without excessive worry. Keeping a low overall weight is not a huge priority.

My initial thoughts, based on research but no personal experience, is two layers of 6-7oz basalt/innegra externally, with multilayer spot patches of glass on holes and cracks and then a full layer of 4 or 6 oz glass internally. Epoxy resin seems like the way to go.

So in summary, the main questions are:

Internal v. external fabric and epoxy work to restore the keep line?

Is my plan for added composite in accordance with my intended use?

I'm a confident DIYer, but have never attempted anything like this before. All thoughts welcome.

I did take it for a paddle on the drive home, and aside from one little 2 tsp/minute crack near the seat, the thing floated no problem. Paddling characteristics were a little peculiar.

Getting all the planking and glass off wasn't nearly as bad as it could have been, due to the poor epoxy and dodgy glass work. The bow end wood was extensively rotted inside, as the glass job was just enough to let a bit of water in, then keep it there. After ~4 hours of cutting, prying, sanding, and a wee bit of swearing, the hull is almost back to the original state, with the addition of a bunch of cracks, 3 dozen screw holes, and a section towards the stern (where I assume his lady friend sat that fateful day) with water intrusion under the outer layers and plenty of puffy/crunchy kevlar fabric.

Unfortunately, being sandwiched between those wood layers for so long has crunched up the keel line of the DY Special, with 2/3s of the boat being 1 to 1.5 inches oilcanned below where it ought to be. I have a few repair questions I was hoping for help with, the first being how to best restore the hull line.

My thought is to make a mold (in essence) out of a 16 foot 2x4 or the like, with an angle that would mimick the gentle angle the boat held through the keel originally. Bracing this off the thwarts ought to hold the original shape while repairs cure and then hold that shape for the duration of the restoration. My question is how much fabric and/or epoxy will be adequate to establish this restored shape, and whether the inside or outside of the hull is the better place to start.

I anticipate using this in the MR 340 this coming year, and the TWS perhaps the year after that. Mostly, it will go on local lakes for fitness, and down flat but twisty central Montana rivers (Musselshell, Missouri, Milk, Marias) where the hull speed will be an asset. I would like the add enough layers of the right fabric to the outside to be able to run into the occasional log and rock without excessive worry. Keeping a low overall weight is not a huge priority.

My initial thoughts, based on research but no personal experience, is two layers of 6-7oz basalt/innegra externally, with multilayer spot patches of glass on holes and cracks and then a full layer of 4 or 6 oz glass internally. Epoxy resin seems like the way to go.

So in summary, the main questions are:

Internal v. external fabric and epoxy work to restore the keep line?

Is my plan for added composite in accordance with my intended use?

I'm a confident DIYer, but have never attempted anything like this before. All thoughts welcome.