You really should have 2 lists, one for the tools you like using and one for the tools you have to have in the shop.

Like and Use

- set of rasp files (

http://www.leevalley.com/en/Wood/page.aspx?p=20144&cat=1,42524 )

- ROS with soft pad attachment (soft pad attachment extends how far the ROS can go on the inside sanding)

- I have the same Shinto Saw Rasp as Jim, that is useful

- Flush cut saw (

http://www.leevalley.com/en/Wood/page.aspx?p=69373&cat=1,42884 )

- Small rip saw (

http://www.leevalley.com/en/Wood/page.aspx?p=50663&cat=1,42884 )

- Carbide scraper (

http://www.leevalley.com/en/wood/page.aspx?p=20094&cat=1,43456,43390 ) ( I actually have the other Lee Valley ones as well)

- Power saw ( table or radial arm)

If you are going to make your strips add

- decent skillsaw

- router table and decent router

- carbide canoe bits

Useful for Canoe building

- lots of 3-4" clamps, look for them on sale ( I have over 50 4" C clamps and use them all at times)

- spring clamps (small through large)

- strip racks (keeps then organized and out of the way, also means they don't get damaged)

- couple of collapsible (or not) 8' work surfaces (used to work on longer pieces of wood , like gunnels, glue ups etc.) mine double as infeed and outfeed tables

- long level is useful for setting up strong back and spanning canoe side to side

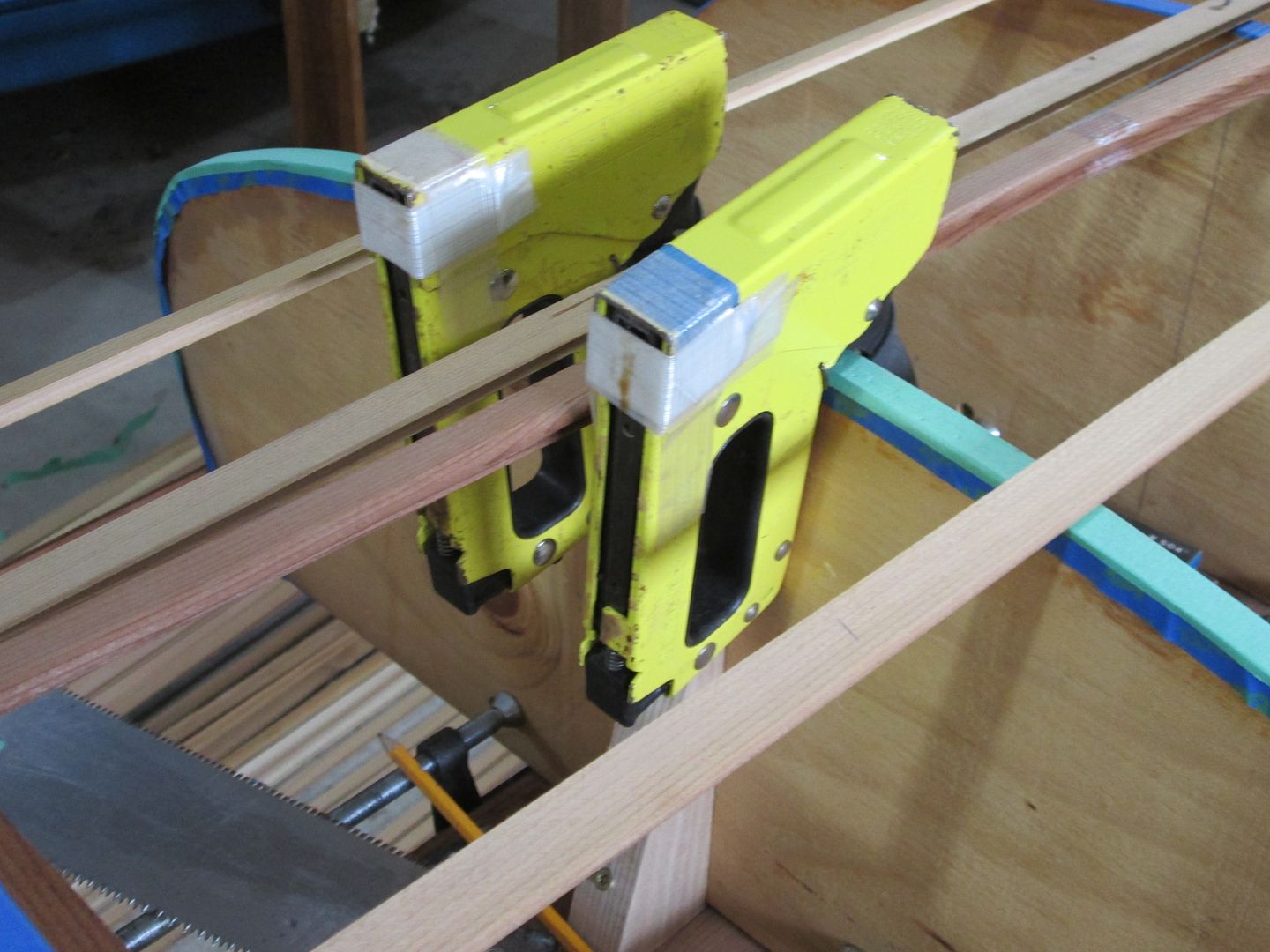

- I build staple less, so cam buckles and shockcord

The reality is that Alan hit the nail on the head, most of the build is with very simple tools ... preparing for the build takes more tools than actually putting the canoe together. The power tools are used mostly for the prep to build, i.e. the strong back build, making the molds and strips, if you make your own.

If you have the basic tools now, probably the best thing you could do to prepare is to watch for a good sale on clamps, buying the amount you are likely to need is one of the pricier items, I got mine on sale for 60% off ....grabbed a dozen off the shelf and had to talk with the store manager when I asked to order 4 dozen more.

Also, I suspect most of us have been adding more tools with each build, as we figure out better ways of getting stuff done ... other than the basics, you may want to plan to add items as you figure out how you are going to complete each step. There are lots of ways of getting the job done, but usually there is one that just makes sense to you and you may need to get a few items to follow that path.

Brian