-

Happy Bastille Day! 🇫🇷🗼

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strip building - Follow the shear or run strips straight?

- Thread starter Alan Gage

- Start date

I find it depends on the type of canoe. For instance, most J. Winter's asymmetrical designs will allow the strips to follow the sheer. The curves are fairly predictable and strip friendly. On traditional canoes, I run a gunwale strip and a straight strip along the sheer and fill in the section between the stems, gunwales and sheer.

It's a lot of fiddly work to fill in the space on traditional canoes. However, there are not many options, unless one wants to just strip straight across and cut the gunwale line. I did that once, but found I had a hard time making both gunwale lines true to each other, it was easier to follow a strip at the gunwale line. Clear as mud?

It's a lot of fiddly work to fill in the space on traditional canoes. However, there are not many options, unless one wants to just strip straight across and cut the gunwale line. I did that once, but found I had a hard time making both gunwale lines true to each other, it was easier to follow a strip at the gunwale line. Clear as mud?

If I did another Jack's Special I would do it the way Mem did, one strip along the sheer and fill in the space, Birds Eye? I figure less curve on the strips should make turning the bilge easier.

I did manage to get both sheers the same on this build by putting the forms back in the boat and marking where the sheer line should be then lining the inwales up on those marks before trimming it down. With the inners in it was much easier to trim evenly.

I did manage to get both sheers the same on this build by putting the forms back in the boat and marking where the sheer line should be then lining the inwales up on those marks before trimming it down. With the inners in it was much easier to trim evenly.

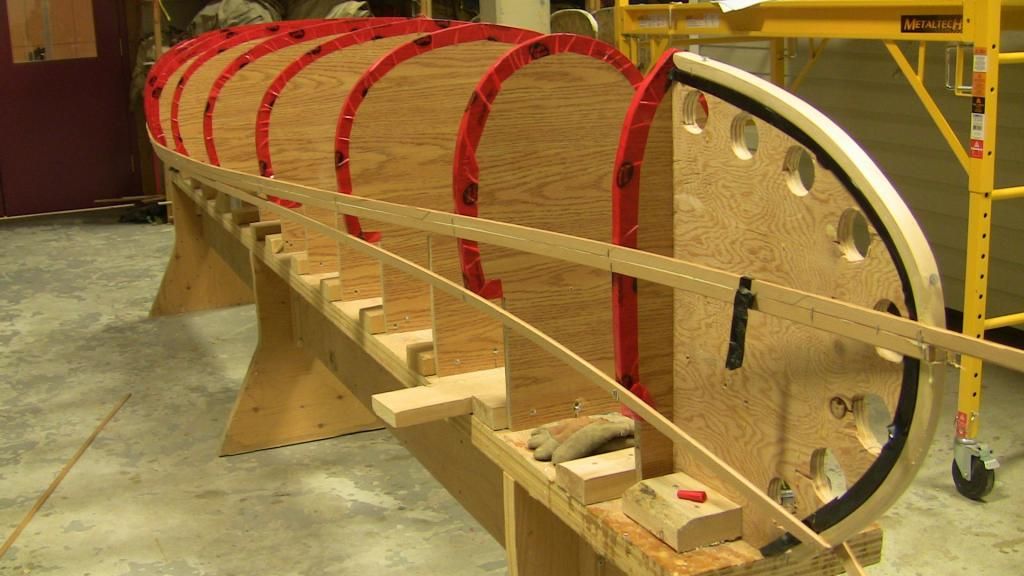

I've done them both ways. The first couple builds I followed the shear the whole way and the rest I've run the second strip straightish. While talking to Jim I was trying to remember why I switched and what I thought the benefit was but it wasn't until the ride home that it finally came to me. It was this solo canoe with extreme tumblehome and it was starting to put some serious stress on the strips at the center of the hull so I ran a strip straight to relieve the stress.

20141108_008 by Alan, on Flickr

20141108_008 by Alan, on Flickr

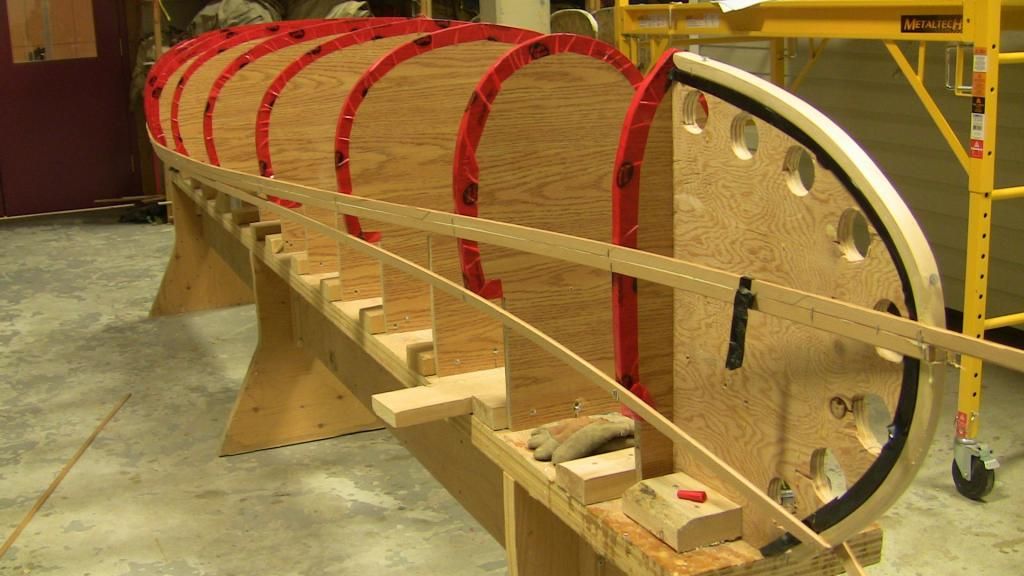

20141109_001 by Alan, on Flickr

20141109_001 by Alan, on Flickr

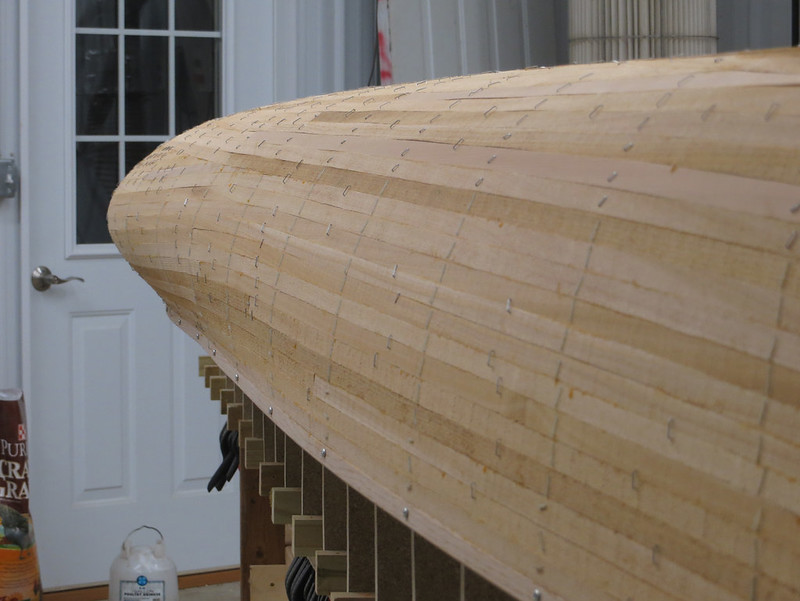

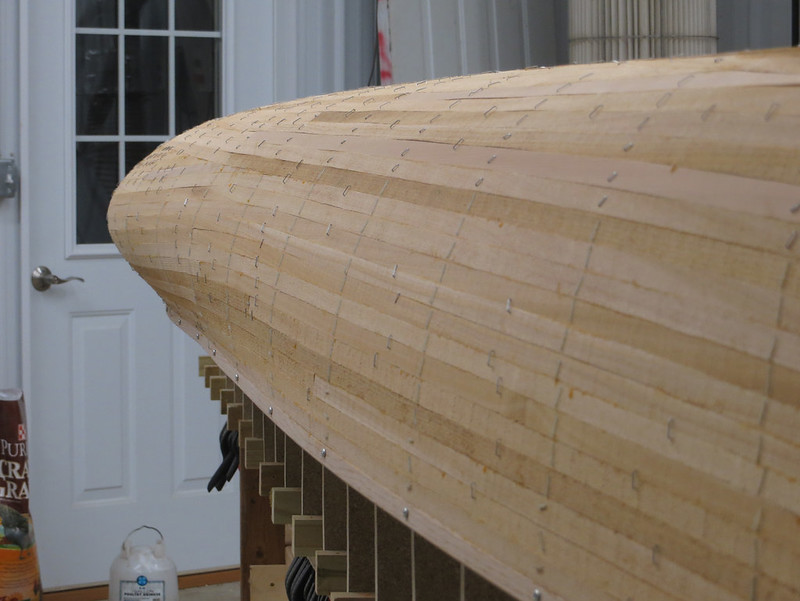

20141111_002 by Alan, on Flickr

20141111_002 by Alan, on Flickr

The canoe after that had some fairly steep rise in the shear at the bow so I did it the same way and I guess it just kind of stuck after that. Next canoe that doesn't have any weird shapes I'll follow the shear again. Sure would be nice not to fill in those holes.

Like Mem my starter strip follows the shear because I'm afraid by the time I shaved and whittled the shear profiles down to get the shape I wanted and the sides even I'll have lost 4 inches.

Alan

20141108_008 by Alan, on Flickr

20141108_008 by Alan, on Flickr 20141109_001 by Alan, on Flickr

20141109_001 by Alan, on Flickr 20141111_002 by Alan, on Flickr

20141111_002 by Alan, on FlickrThe canoe after that had some fairly steep rise in the shear at the bow so I did it the same way and I guess it just kind of stuck after that. Next canoe that doesn't have any weird shapes I'll follow the shear again. Sure would be nice not to fill in those holes.

Like Mem my starter strip follows the shear because I'm afraid by the time I shaved and whittled the shear profiles down to get the shape I wanted and the sides even I'll have lost 4 inches.

Alan

We did have some great Shop Talk, but paddling was even better ! It was great to see Alan work some white water with his new CF !

Have to agree that design can dictate the stripping method. Recurved ends often require the stair step method.

I, like Muskrat, fall for the beauty of following the shearline method. In Alan's and my discussion, each method puts the stress on the strip in different places.

Following the shear is a time saver for me, especially with the solos, and relatively mild tumblehomed hulls I build.

We also entered into discussion of splicing strips. Need to start another thread on this one. ! HA !

Bead and cove is still the best thing since sliced bread !

Jim

Have to agree that design can dictate the stripping method. Recurved ends often require the stair step method.

I, like Muskrat, fall for the beauty of following the shearline method. In Alan's and my discussion, each method puts the stress on the strip in different places.

Following the shear is a time saver for me, especially with the solos, and relatively mild tumblehomed hulls I build.

We also entered into discussion of splicing strips. Need to start another thread on this one. ! HA !

Bead and cove is still the best thing since sliced bread !

Jim

Have to agree that design can dictate the stripping method. Recurve ends often require the stair step method.

Jim

I would think that would depend on whether going with inner stems or not. As for splicing, if you are doing staples then you can either butt joint or scarf, if doing no staples, then go with scarfs. I doubt it matters either way since the wood is only a core for the glass layers, but for some of us it is more aesthetically pleasing to not have butt joints.

As for splicing, if you are doing staples then you can either butt joint or scarf, if doing no staples, then go with scarfs. I doubt it matters either way since the wood is only a core for the glass layers, but for some of us it is more aesthetically pleasing to not have butt joints.

Since we're both die hard butt and staple men we were debating the merits of splicing over the form or between them.

Alan

Since we're both die hard butt and staple men

The Plaid Prancer approves this message.

I almost always start at the 4" waterline (or design displacement waterline), and work my way down to the sheer, and up to the keel. Oh, and I strip one side at a time...

Then repeat the process on the second side, after trimming the stems and keel line

I like my strips parallel to the water. And most of my boats have low rise sheer lines.

As far as butt vs scarf, I must admit I'm a butt guy, always have been!

Then repeat the process on the second side, after trimming the stems and keel line

I like my strips parallel to the water. And most of my boats have low rise sheer lines.

As far as butt vs scarf, I must admit I'm a butt guy, always have been!

Stripperguy

I have a few questions.

What do you use to pull your staples ? I see it looks like you use an electric stapler. Does it sink the staples into the strip ?

I wonder if stripping one side at a time causes any distortion to the stems ? I would think the side you are stapling would pull on the stem forms.

Lastly, once you are done glassing, and want to remove the hull from the forms, how do you remove the screws holding the forms to the strong back ?

Lastly ! How far are you from the Twin Cities ? Alan and I will both be at Mid West Mountaineering's Spring Expo. It would be great to meet up !

Jim

I have a few questions.

What do you use to pull your staples ? I see it looks like you use an electric stapler. Does it sink the staples into the strip ?

I wonder if stripping one side at a time causes any distortion to the stems ? I would think the side you are stapling would pull on the stem forms.

Lastly, once you are done glassing, and want to remove the hull from the forms, how do you remove the screws holding the forms to the strong back ?

Lastly ! How far are you from the Twin Cities ? Alan and I will both be at Mid West Mountaineering's Spring Expo. It would be great to meet up !

Jim

Stripperguy

I have a few questions.

What do you use to pull your staples ? I see it looks like you use an electric stapler. Does it sink the staples into the strip ?

I wonder if stripping one side at a time causes any distortion to the stems ? I would think the side you are stapling would pull on the stem forms.

Lastly, once you are done glassing, and want to remove the hull from the forms, how do you remove the screws holding the forms to the strong back ?

Lastly ! How far are you from the Twin Cities ? Alan and I will both be at Mid West Mountaineering's Spring Expo. It would be great to meet up !

Jim

Jim,

I'd love to meet you and Alan sometime...I'm sort of retired now, MDB and I do like to travel. I am right next to Albany, NY, so I'm about 45 minutes from the ADK's and about 1003 minutes from Des Moines. I do plan to attend a forum meet/paddle in May, but it's a different forum and in Newcomb, NY (heart of the ADK's)

For pulling staples, I have a sharpened can opener (remember those?). When I built a stripped sailboat, I used an air stapler and needed to use a modified offset screwdriver to pull the 1" long staples. (screwdriver was a 9th grade shop project)

I generally use a stubby strip to protect the hull from the can opener fulcrum.

The electric stapler could easily drive the staples well below the surface. But remember that Newton dude and his suggestions? (some people call them laws)...if you don't hold the stapler too firmly, then it can't react all of the driving force and the staples will stay above or at the surface. It's definitely a practiced skill.

My stem forms are securely attached to the #1 and #last forms, as well as pinched in place with a couple screws in the strongback on each side. I haven't had any noticeable distortions, but the way that I strip puts little stress on the stem form in the transverse plane. I do occasionally staple a strip or two on the second side while I strip the first side, just in case. I'm definitely a suspenders/belt/rope kind of guy. (remember, I spent 30 years in R & D, mostly DOD stuff)

When I'm ready to pop a glassed hull off the forms, I remove the carriage bolts that hold the forms to the strongback. Nuts are always on the underside of the strongback. Stem form and #1 form are a unit, and usually stay in the hull during the flip, whether I want that or not.

I find it fascinating that we have all developed and honed our individual methods, and yet we have so many similar techniques.

I really enjoy the give and take here. Even though I've been building strippers since 1978, I still have learned quite a few tricks from these shared build threads.

Thanks ! I love sharing methods. I have learned SOO many things from beginners, as well as the more experienced !

Since 78. You are way ahead of me. So I'm guessing you were in the Polyester resin days. I did one Polyester canoe, and epoxied every one since.

Here's a pic of a staple puller, that a beginner introduced me to. They are a real tool ! I have an old "Hamm's Beer" can opener. Yes sharped, and wrapped with many layers of red tape.

My canoe building model demonstrating the pullers use.

Jim

Since 78. You are way ahead of me. So I'm guessing you were in the Polyester resin days. I did one Polyester canoe, and epoxied every one since.

Here's a pic of a staple puller, that a beginner introduced me to. They are a real tool ! I have an old "Hamm's Beer" can opener. Yes sharped, and wrapped with many layers of red tape.

My canoe building model demonstrating the pullers use.

Jim

I bought a staple puller like Jim has but I prefer using a simple pair of pliers. Since the staple heads are all proud just grab and yank. The puller worked nice but I like to move fast and too often the staple I pulled would get hung up in the mechanism and be stuck underneath the puller. It would take me two or three more staples to realize this and by then it would leave some nice dents in the hull.

For the pliers method grab the handle with both hands and quickly jerk the staple straight out, no prying. Sometimes it helps to twist it back and forth slightly before pulling to loosen it up.

Fun hearing how everyone else does it.

So back to butt jointed strips: Where does everyone make the joint? I like to do mine over the form. Of course on the forms towards the stems, where the strips only contact one edge of the form, the strips don't join properly. But since the staples aren't driven flush I can pull the strip out slightly until it's lined up with the other and the tension from the staple leg holds it in place.

I also put in the staples sideways instead of vertical where the strips join so one leg catches each strip. The staple looks like this . . instead of like this :

Alan

For the pliers method grab the handle with both hands and quickly jerk the staple straight out, no prying. Sometimes it helps to twist it back and forth slightly before pulling to loosen it up.

Fun hearing how everyone else does it.

So back to butt jointed strips: Where does everyone make the joint? I like to do mine over the form. Of course on the forms towards the stems, where the strips only contact one edge of the form, the strips don't join properly. But since the staples aren't driven flush I can pull the strip out slightly until it's lined up with the other and the tension from the staple leg holds it in place.

I also put in the staples sideways instead of vertical where the strips join so one leg catches each strip. The staple looks like this . . instead of like this :

Alan

OK, back on track ! Between the forms. No staple needed with the clamp, at least not at the butt joint. It would just be a hindrance.

Here's a pic.

There is plenty of room for the next strip to fit beneath the clamp. Once the next strip is on, no need for the clamp and blocks.

The beauty of bead and cove, alignment made easy.

The blocks are wrapped in packing tape, to prevent sticking.

Simple, and effective method. And no hang ups when I sand or scrape. The real trick is to make the splice in a low stress area.

Jim

Here's a pic.

There is plenty of room for the next strip to fit beneath the clamp. Once the next strip is on, no need for the clamp and blocks.

The beauty of bead and cove, alignment made easy.

The blocks are wrapped in packing tape, to prevent sticking.

Simple, and effective method. And no hang ups when I sand or scrape. The real trick is to make the splice in a low stress area.

Jim

Last edited:

OK, back on track ! Between the forms. No staple needed with the clamp, at least not at the butt joint. It would just be a hindrance.

Here's a pic.

There is plenty of room for the next strip to fit beneath the clamp.

Jim

Oh yeah. I wasn't even thinking about room for the next strip to fit between the jaws. That would work just dandy.

Alan

Keep talking, you guys. By the time I get around to doing my first, I will be well educated!

Since we're on a roll how does everyone treat the stems when fiberglassing? I wrap mine. I'd show pictures of the process but I checked and don't have any. Probably because my hands are slathered with epoxy at the time and taking pictures is the last thing on my mind.

Alan

Alan

Outer stems, I cut the main layer flush with the ends, While it is still wet, I lay on two bias strips. The big one first.

The inside, I overlap the two sides. I glass the entire inside, when I'm happy, I address the stems. If I try and glass the stems as I work the main layer I always get into to trouble.

There are many videos out there. Some so fast, you can't make heads or tails of them ! Some skip the parts that are the most troublesome.

We need to get together and video the glassing of your little canoe !

Jim

The inside, I overlap the two sides. I glass the entire inside, when I'm happy, I address the stems. If I try and glass the stems as I work the main layer I always get into to trouble.

There are many videos out there. Some so fast, you can't make heads or tails of them ! Some skip the parts that are the most troublesome.

We need to get together and video the glassing of your little canoe !

Jim

Stems are always wrapped with multiple layers of bias cut glass, some hulls get a last layer of Dynel.

Inside, the stems are not pretty. I generally use a full length of fiberglass, and fold/trim the stems in as carefully as possible. Always cut and fit dry.

Ultimately, I (or an unfortunate helper) end up sticky to my forearms.

I offer this photo sequence, with the pigmented resin, there is plenty of contrast to show how the bias cut cloth wraps the compound curves at the stems.

Disclaimer: My son Josh did not actually lick the resin!!

Inside, the stems are not pretty. I generally use a full length of fiberglass, and fold/trim the stems in as carefully as possible. Always cut and fit dry.

Ultimately, I (or an unfortunate helper) end up sticky to my forearms.

I offer this photo sequence, with the pigmented resin, there is plenty of contrast to show how the bias cut cloth wraps the compound curves at the stems.

Disclaimer: My son Josh did not actually lick the resin!!

Similar threads

- Replies

- 1

- Views

- 339

- Replies

- 73

- Views

- 9K