I trim the cloth to around 2" past the shear. Save that cloth, as you will find uses for it ! It's good to laid your cloth on a Bias.

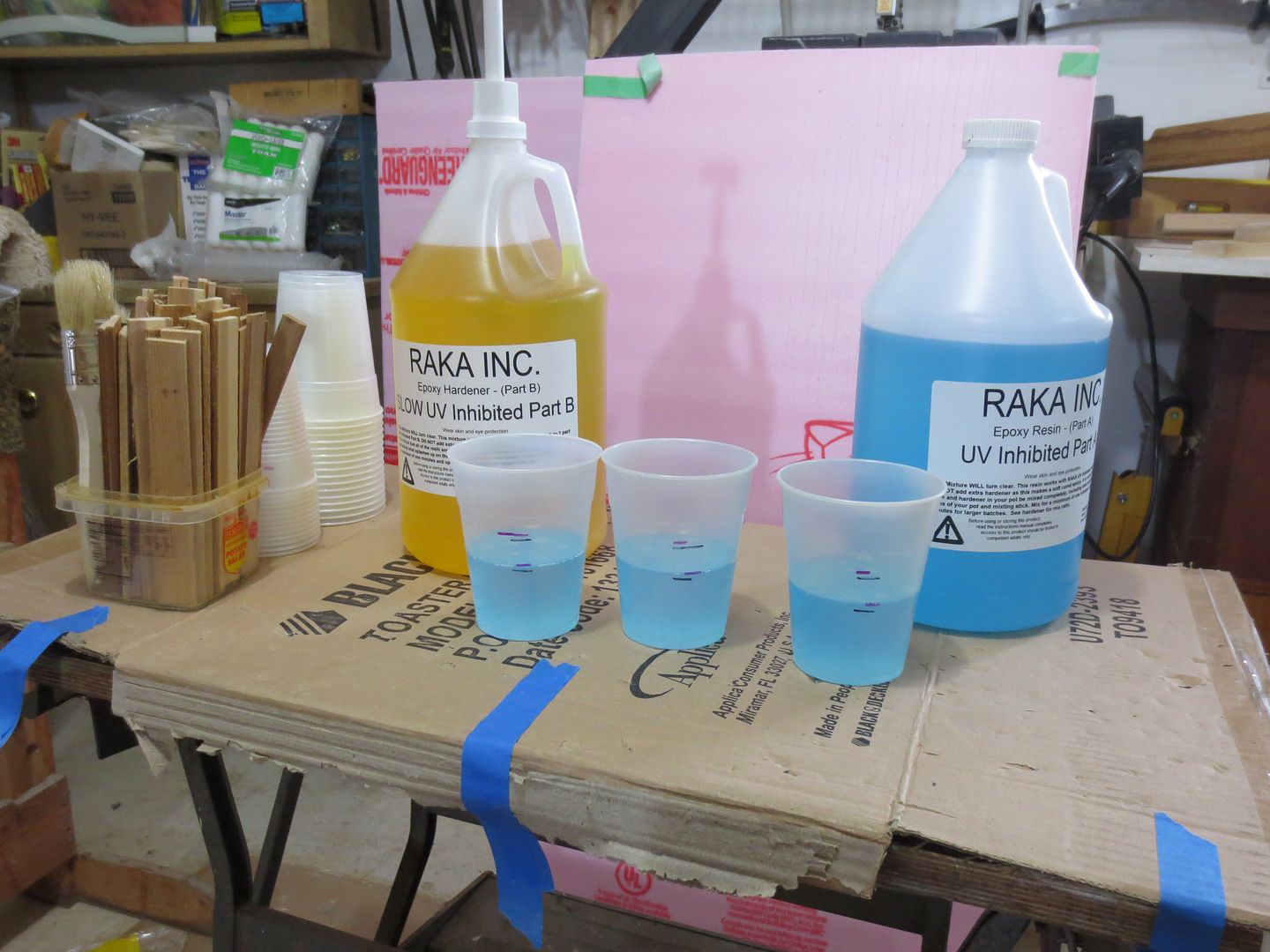

I like to mix up 9 oz batches, ONE at a time. It seems just about right for timing. If you mix too big a batch, it could kick over on you, before you get it on the hull !

I would prefill 5 cups with 6 oz of resin, for a canoe the size of yours. Then all I have to do is add hardener, when needed fon the next cup.

I use clear smooth sided 16 or 20 oz cups from Walmart. I premark them..

Notice the different marks ? I double checked the black marks with a more accurate measuring cup. The top lines are correct.

I premark enough cups to easily do all the coats on my canoe.

We all have slightly different methods, this has worked great for me !

I would guess your wet out coat to take 5 or 6 9 oz batches. Maybe 4 cups for the next fill coat. It varys with your method of application.

If you have all ready applied a seal coat, and are waiting a week to wet out the cloth, I would sand the hull lightly with say 220 grit paper. This will do two things, one, insure a good bond, and remove any imperfections. Run your hand over the hull. It will find any imperfections, and I can almost guarantee there are some ! They will prevent your cloth from laying tight against the hull. You won't be happy later when you sand the entire hull !

What resin are you using, and how are you going to apply it to the hull?

Maybe put some plastic on the floor ?

Looks great ! I'd love to be there to help you glass !

Jim