As some of you know, we are moving into dip-net season. Some of you saw my offerings while outfitting my own “dip ship”; and now i have a young family who are excited about the prospect of putting up a bunch of red’s and i‘m getting to mentor them along the way.

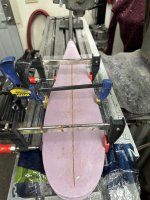

I knew a lady with an old Coleman 17ft canoe that had a pretty good leak in the bow, so we bought it right and right now we’re repairing and outfitting it for the soon to be season opener. These folks can spell canoe but that’s about it, so this is a lot of fun for both of us.

While trying to cover all the bases i realize how much i normally take for granted so i catch my self slowing down and backing up a lot. They are good students and we will be ready in time. I intend to haul all the gear to the lake and give them some hands on as well. Who would have though this old Coleman could be so much fun?

I knew a lady with an old Coleman 17ft canoe that had a pretty good leak in the bow, so we bought it right and right now we’re repairing and outfitting it for the soon to be season opener. These folks can spell canoe but that’s about it, so this is a lot of fun for both of us.

While trying to cover all the bases i realize how much i normally take for granted so i catch my self slowing down and backing up a lot. They are good students and we will be ready in time. I intend to haul all the gear to the lake and give them some hands on as well. Who would have though this old Coleman could be so much fun?