Or at least I hope it will be. Every fall I have grand plans to work in the shop on my many projects but the cold and dark usually win and I end up being a bum just sitting in the house reading books and eating.

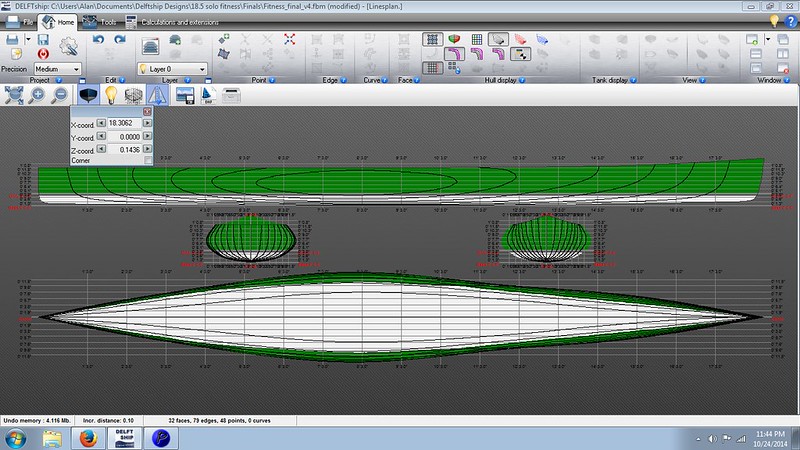

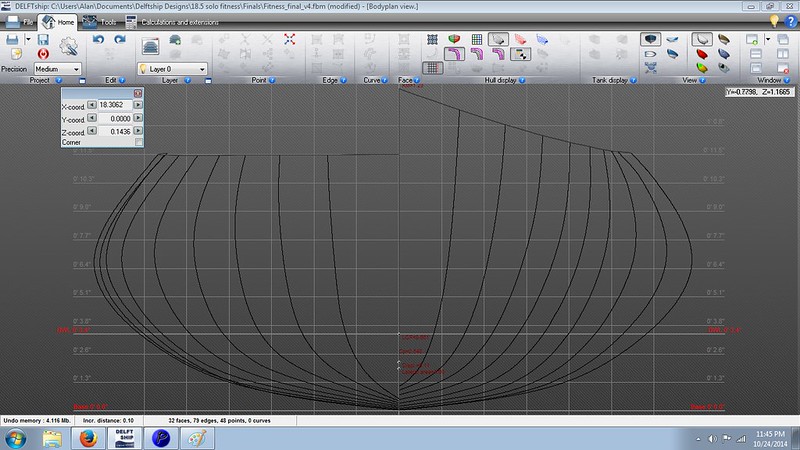

To help keep me motivated I just ordered 100 board feet of red cedar and 25 board feet of cherry. Hoping to get at least 3 canoes built before the thaw. I'd really like to get one done while there is still a spot or two of open water to see if it will work or needs to be redesigned.

Finally started working on getting my shop organized this past weekend. Last January I'd cut out all the fronts, backs, and sides for 35 drawers that need to go in the shop cabinets. That's where they sat until yesterday when I got all the dadoes cut, cut out the bottoms, and started putting them together. Hopefully that project will be done by the weekend and then I can start putting stuff away. I'll probably build a second strong back as well this weekend. Need to hang a couple more lights too. Hopefully the weekend after that will see another stripper taking shape!

Alan

To help keep me motivated I just ordered 100 board feet of red cedar and 25 board feet of cherry. Hoping to get at least 3 canoes built before the thaw. I'd really like to get one done while there is still a spot or two of open water to see if it will work or needs to be redesigned.

Finally started working on getting my shop organized this past weekend. Last January I'd cut out all the fronts, backs, and sides for 35 drawers that need to go in the shop cabinets. That's where they sat until yesterday when I got all the dadoes cut, cut out the bottoms, and started putting them together. Hopefully that project will be done by the weekend and then I can start putting stuff away. I'll probably build a second strong back as well this weekend. Need to hang a couple more lights too. Hopefully the weekend after that will see another stripper taking shape!

Alan