I've needed new deck plates for my Courier after building several that have failed. This was trying to follow the one existing deck that came with the hull. All have failed in one way or another, don't ask. Bored at work one day I looked up making carbon fiber sheets and it didn't look to hard. I have had a roll of it around for a few years now and have used some up but thought dang I will have enough to make a few sheets for new decks. I got home from work today and started laying everything out and started thinking I hope I don't morph into Alan!

Using the original deck as a template I cut out the shape of it and then decided to use blue tape on the edges but that turned out a disaster so switched to just making square blanks that I'll cut and shape later when they cure.

What amazed me was because I was laying four layers on it ate up the roll of cloth pretty quick. If this works I'll have to order another batch of CF to make a second deck. Much like steam bending wood I have absolutely no idea of what I'm doing but figure it is worth the try. I use West System because it is available local but this time I bought a can of 205 quick hardener vs the usual 206 slow.

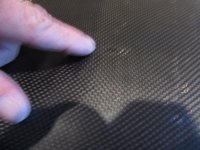

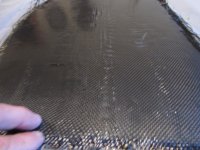

Basically I cut 4 pieces of the same size, smeared the first with resin then laid the second on and using a brush smoothed that into the first layer with a touch of resin, added the third and added a healthy dose of resin and worked it into the other layer and then the fourth layer I smoothed out with a light layer of resin which I smoothed out so no air bubbles appeared. Peel Ply on top of that and am letting it sit.

Now, I laid everything on a large piece of plexiglass but had no idea if resin would stick to that so going to EpoxyWorks website they state that 3 mil plastic will act as a release so I went with that as I had it on hand.

Here's a link to making DIY sheets: http://www.youtube.com/watch?v=3uhR4jdFiS4

Link to Epoxy Works and release options: http://epoxyworks.com/index.php/what...poxy-to-stick/

I really like trying new things whether they fail or not, hoping for a NOT fail this time.

Not sure why the photos came out in sequence backwards but basically what I started with to peel ply steps. Sorry bout that.

Using the original deck as a template I cut out the shape of it and then decided to use blue tape on the edges but that turned out a disaster so switched to just making square blanks that I'll cut and shape later when they cure.

What amazed me was because I was laying four layers on it ate up the roll of cloth pretty quick. If this works I'll have to order another batch of CF to make a second deck. Much like steam bending wood I have absolutely no idea of what I'm doing but figure it is worth the try. I use West System because it is available local but this time I bought a can of 205 quick hardener vs the usual 206 slow.

Basically I cut 4 pieces of the same size, smeared the first with resin then laid the second on and using a brush smoothed that into the first layer with a touch of resin, added the third and added a healthy dose of resin and worked it into the other layer and then the fourth layer I smoothed out with a light layer of resin which I smoothed out so no air bubbles appeared. Peel Ply on top of that and am letting it sit.

Now, I laid everything on a large piece of plexiglass but had no idea if resin would stick to that so going to EpoxyWorks website they state that 3 mil plastic will act as a release so I went with that as I had it on hand.

Here's a link to making DIY sheets: http://www.youtube.com/watch?v=3uhR4jdFiS4

Link to Epoxy Works and release options: http://epoxyworks.com/index.php/what...poxy-to-stick/

I really like trying new things whether they fail or not, hoping for a NOT fail this time.

Not sure why the photos came out in sequence backwards but basically what I started with to peel ply steps. Sorry bout that.