undecided on the substrate. I did like your cedar substrate carbon wrapped gunnels.

For a 16.5' boat they seem to run about 5 pounds by the time it's all said and done.

Alan

undecided on the substrate. I did like your cedar substrate carbon wrapped gunnels.

Partal is just a brand name for PVA, at least that's my understanding.

The wood core, is a lot of extra time and work. CF Nokomis has a fairly flat bottom, but it's plenty stiff now.

Love the Experimentation going on !

I have yet to install flotation chambers, but CF Nokomis, at 16'4'', is up to 30# with the wood insert glassed.

Trim weight is the real key to keeping these hulls light. I'm still debating this, in my mind.

My compliments as to the clean work area ! My Wife has even offered to come down and clean mine ! She's TOO Good !

Jim

For a 16.5' boat they seem to run about 5 pounds by the time it's all said and done.

Alan

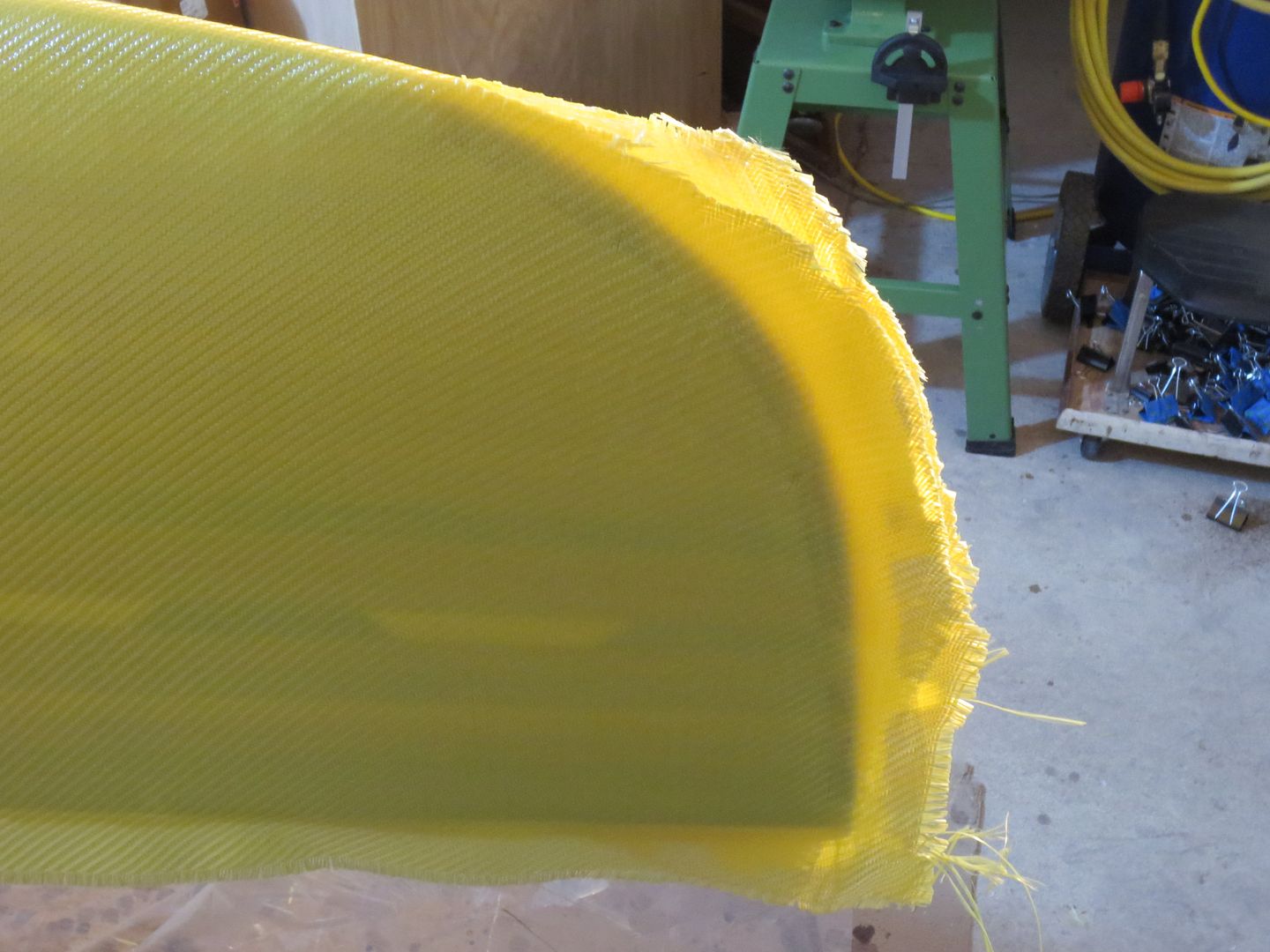

Dang Stripperguy, you don't waste any time. Looking good so far. For the stems, ever thought of molding one layer of fabric on the stripper stem, then attaching it with more layers onto the shell?

I use 4 mm Lantor Coremat for my ribs in 3 inch strips with two layers of kevlar over top. It is much lower profile than commercial ribs or cores. So far they have worked great. No oil canning, but still plenty fexible when sliding over or coming to abrupt halts on rocks. That is on a layup of 2 layer 6 oz s glass and 1 layer 9 oz stitched kevlar. If I didn't have extra around I probably would have used 2 mm on my last project instead. The coremat does soak up a lot of resin but that ends up making it part of the laminate, which I don't worry about delaminating like a foam core rib. Just some food for thought.

No, I did not think of molding some stem pieces first...I wish I did, that's an eggsalad idea!

I agree. Great idea.

Hmmm, "eggsalad idea"? That must be an east coast thing.

Alan

Wow SG! I am looking forward to the rest when you return!

Jason

You're selling your house with a boat under construction!? Put that house sale on hold, you've got a more important project to finish.

I don't build in flotation. I probably should put in some small tanks for when I can't be bothered with air bags, but then they would get in the way of the bags when I need them. It's a quandry. If I have to self rescue in deep water I want more than the tanks could provide. In shallow water I don't think I need any floation since the boat can't sink anyway, or at least not deep enough to cause a problem.

It's interesting in drift boats they don't use any flotation with the theory that they'd rather the boat sink and stick to the bottom so there isn't a moving hazard that a floating person could hit or get pinned by.

SG, the canoe keeps coming along nicely. It's probably too late already, but if you don't want that foam to stay in the stems you should be able to dissolve it with acetone or other solvent.